PLM and ERP are two topics that always can trigger an interest from industrial companies and software vendors. The ubiquitous expansion of ERP systems (show me a large enough OEM that is not trying to answer the question of what to do with ERP) makes many companies to think that ERP is a starting point of all business processes. At the same time, the growing complexity of product development brings questions about how to organize engineering and product information, how to manage traceability between engineering and manufacturing BOMs and how make design engineers aware about business and supply chain factors that can impact the design. All these and many other related questions are always triggered when the “PLM-ERP” discussion is kicked off.

My attention was caught by Prof. Dr. Jörg W. Fischer LinkedIn article with a bold statement saying that we (Prof. Dr. Jörg W. Fischer and Martin Eigner finally “solved PLM & ERP”). You can see the cool picture below and the link to the article.

Here is the passage from the post that I found interesting:

What we repeatedly notice in industry discussions is the enormous increase in the complexity of discussions around digitalization, PLM, ERP, CPQ… 🤯 We are experiencing a level of complexity that companies can hardly manage anymore. Humanity has repeatedly proven that it can solve complex problems when they are described precisely and made teachable and understandable. This is a task for science, i.e., for professors.

In this case, not for classical research science, but for applied science in the transfer to industry. Interestingly, the approaches we need to use are derived more from the humanities, i.e., specifically from the science of logic according to Hegel, rather than from precise sciences like engineering. 🧠🔍

It is about defining a level of language in a suitable level of abstraction that allows a uniform, neutral (i.e., IT-system-neutral) discussion of the issues. Since this does not exist today, it is impossible to create precise maps of what is. One could say that we are in business science, in PLM and ERP, in a time like Columbus, when no map of the world existed, and it was not certain whether one would fall off the edge of the world. 🌍🗺️

We are convinced that we have found a fundamental methodology on whose basis a complete and consistent mapping system for companies can emerge, from strategy development to implementation. If we have succeeded – and we are very confident – then I think we can claim that we have solved PLM & ERP. At least in part 😊

To learn more about the methodology, here is the link – Maps for Enterprises: the first continuous enterprise model end-to-end, seamless & consistent, based on Theory of Aggregation and Resolution Layers.

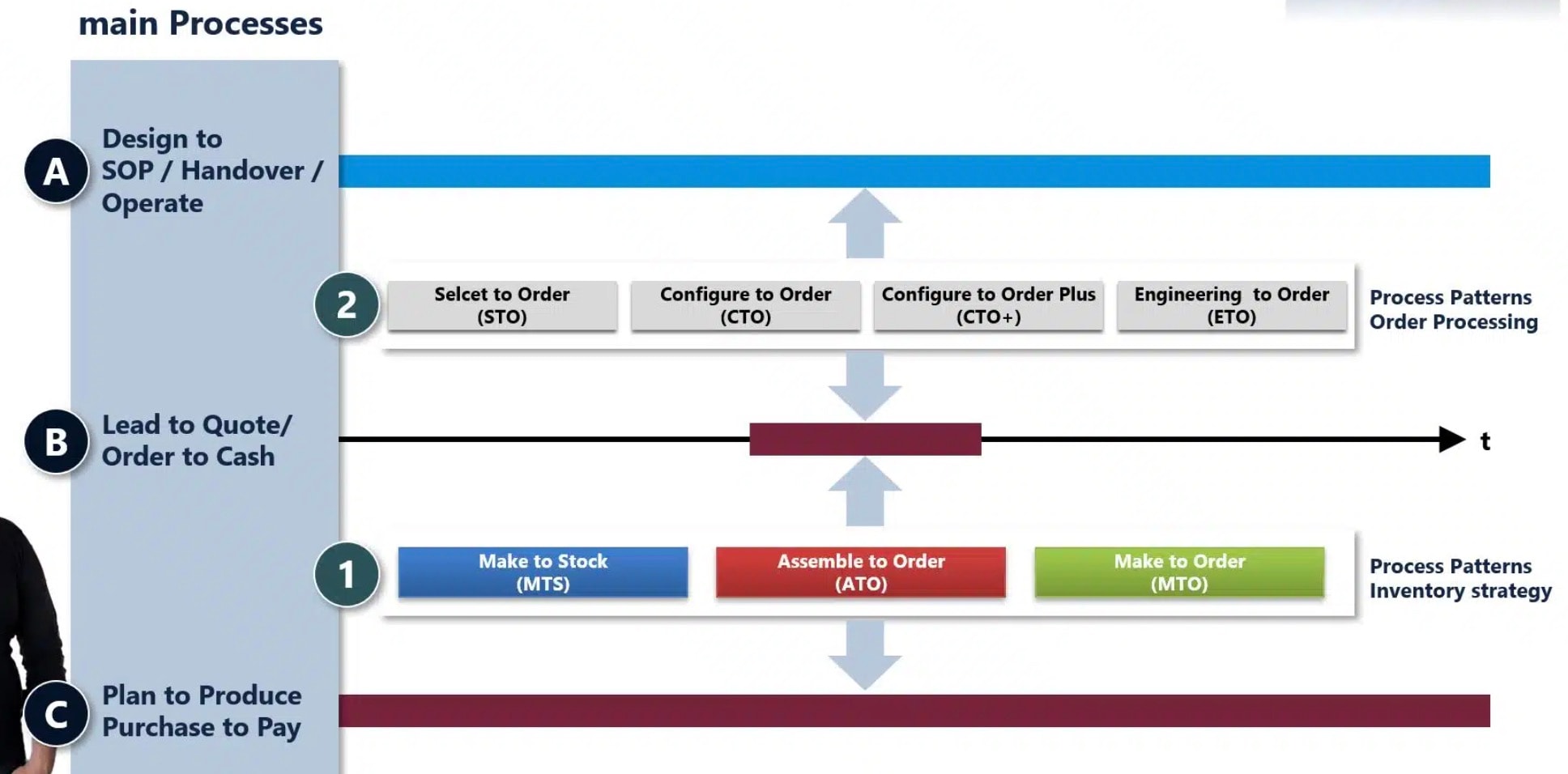

The main point in the presentation is that end-to-end processes don’t exist alone, but integrated between each other (which makes PLM and ERP to work together) via a set of more granular processes with information architecture that is needed to support it.

The presentation and video made me think about possible challenges and potential solutions to undertake to implement this approach, which leads to the question of intertwined PLM and ERP software environment. Solving the challenges associated with PLM and ERP involves creating a cohesive environment where product data and business processes are seamlessly integrated.

Here’s my take on how to achieve that:

Understand the Core Challenges both PLM and ERP

Each system in the PLM+ERP equation comes with a baggage of challenges. You need to acknowledge them to understand the level of complexity each of these systems is managing:

Here is my take on the top 5 PLM Challenges:

- Data Management: Ensuring accurate, consistent, and accessible product data across all stages.

- Collaboration: Facilitating seamless communication and collaboration among engineering, manufacturing, and other departments

- Process Optimization: Streamlining product development processes to reduce time-to-market and improve product quality.

- Compliance and Traceability: Ensuring products meet regulatory requirements and maintaining traceability of changes throughout the product lifecycle.

The last one is actually hitting the main point of “PLM+ERP solver”. It is all about integration. Integrating PLM with other systems like ERP, CAD, and SCM to create a unified and efficient workflow is the challenge to solve to built a cohesive solution.

Here is my take on the top 5 ERP Challenges:

- Data Accuracy: Maintaining accurate and real-time data across all business functions to support decision-making.

- Process Efficiency: Streamlining and automating business processes to improve efficiency and reduce operational costs.

- Scalability: Ensuring the ERP system can scale with the business as it grows and adapts to changing needs.

- User Adoption: Facilitating user training and adoption to maximize the system’s benefits.

And, exactly how with PLM, there is a main “PLM+ERP” point – system integration. It is about ensuring ERP systems work seamlessly with other enterprise systems like PLM, CRM, and SCM.

Develop a Unified Information Model

The way to solve problems of PLM to ERP integration, connecting computer aided design (CAD software), enterprise resource planning (ERP software) and supply chain management (SCM), connecting all these disciplines to an overarching product lifecycle management and business management software is where the complexity Prof. Dr. Jörg W. Fischer is talking about.

From my perspective, creating a unified information platform that integrates PLM and ERP functionalities is the first step towards solving these challenges. This platform should act as a single source of truth for all product and business data. The benefits include improved data accuracy, reduced redundancies, and enhanced collaboration across departments.

Ensure Data Synchronization

Data consistency and synchronization between PLM and ERP systems are crucial to avoid discrepancies and redundancies. Implementing a robust data management strategy that includes real-time data updates and automated synchronization processes ensures that all departments have access to the most accurate and up-to-date information.

The core for integrated system and end-to-end processes is to introduce a unified product model that is capable to withstand both PLM and ERP software system connectivity. The information model that is capable to connect design tools, product design (mechanical and electronic), project management, BOM management, technical drawings, CAD technology, manufacturing planning, detailed design, data management, manufacturing methods, production scheduling, supply chain and many other disciplines together.

Automate Workflows

Automating workflows that span both PLM and ERP processes can significantly enhance efficiency and reduce manual intervention. Automated workflows ensure that tasks are completed faster and with fewer errors, leading to improved productivity and reduced operational costs.

Workflow is not a new technology in both PLM and ERP. However, usually it runs in an isolated way in one of the systems. How workflow system can be automated using integrated information model is a question that needs to resolved.

Enhance Collaboration

Improving collaboration between departments that rely on both PLM and ERP data is essential. This can be achieved by implementing collaboration tools that facilitate communication and data sharing among engineering, manufacturing, procurement, and other departments. Enhanced collaboration leads to better decision-making and faster problem resolution.

Leverage Advanced Analytics

Utilizing advanced analytics to gain insights from combined PLM and ERP data supports strategic decision-making. Analytics tools can help identify trends, uncover inefficiencies, and predict future outcomes, enabling companies to make informed decisions that drive business success.

Focus on User Adoption

Ensuring that users are adequately trained and comfortable with the integrated PLM and ERP system is critical for maximizing its benefits. Providing comprehensive training programs, user-friendly interfaces, and continuous support helps facilitate user adoption and engagement.

Prioritize Scalability

As businesses grow and evolve, their PLM and ERP systems must be able to scale accordingly. Choosing scalable solutions that can adapt to changing business needs ensures long-term viability and supports ongoing growth and innovation.

Implement Robust Security Measures

With the integration of PLM and ERP systems, data security becomes even more critical. Implementing robust security measures, such as encryption, access controls, and regular security audits, helps protect sensitive data and ensures compliance with regulatory requirements.

Conclusion

Solving the challenges of PLM and ERP requires a holistic approach that involves creating a unified information model ensuring data synchronization, automating workflows, enhancing collaboration, leveraging advanced analytics, focusing on user adoption, prioritizing scalability, and implementing robust security measures. This unified product model (or service) can become a bridge for integrated end-to-end processes Prof. Dr. Jörg W. Fischer is talking about. By addressing these areas, companies can achieve seamless integration of PLM and ERP systems, leading to improved product development, operational efficiency, and overall business performance.

In my earlier articles, I discussed the need for integrated product model and how such a model can become a foundation for digital thread. In another article, I discussed how to bring a new digital model instead of multiple BOMs. My last article gives you an example about how to build a graph-based model to resolve complexity of PLM and ERP integration.

Incorporating modern solutions like cloud technologies and open product models can further enhance the effectiveness of PLM and ERP integration, enabling businesses to stay competitive and agile in today’s dynamic market environment.

Just my thoughts…

Best, Oleg

PS. In my next article, I will speak about practical steps of integration PLM and ERP using unified product information model. Stay tuned.

Disclaimer: I’m the co-founder and CEO of OpenBOM, a digital-thread platform providing cloud-native PDM, PLM, and ERP capabilities. With extensive experience in federated CAD-PDM and PLM architecture, I’m advocates for agile, open product models and cloud technologies in manufacturing. My opinion can be unintentionally biased.