Last week, I attended Autodesk University 2024 in San Diego. I came to share OpenBOM experience of building digital workflows and integrating Fusion data into downstream data flows including procurement and vendor communications.

But, besides that, AU 2024 was a great opportunity to explore Autodesk’s latest advancements in design, manufacturing, and data management—areas that align closely with my interests and topics I follow for many years.

AU 2024 manufacturing keynote and PLM summit offered a good insights into Autodesk’s strategic direction, especially in how they plan to tackle the growing complexity of product development and the acceleration of manufacturing demand.

Autodesk Fusion is a central piece of the strategy and, as it was mentioned by Jeff Kinder, Autodesk Senior Vice President of Design and Manufacturing shared in his AU 2024 main keynote presentation.

Below are some of my takeaways and news about key themes and what I think about the future direction Autodesk is taking.

AU Design and Manufacturing Keynote: Accelerating Innovation Using Data

The keynote from Srinath Jonalagadda set the stage by discussing the enormous growth of the $10 trillion manufacturing industry, which is expected to rise to $16 trillion. The key challenge manufacturers face today is balancing the acceleration of demand with the increasing complexity of products.

Srinath highlighted a fundamental question: How can manufacturers use data to change collaboration, unlock the full potential of AI, and innovate faster? Here are my key lesson learned:

Seamless Data Connectivity: The Foundation for Future Innovation

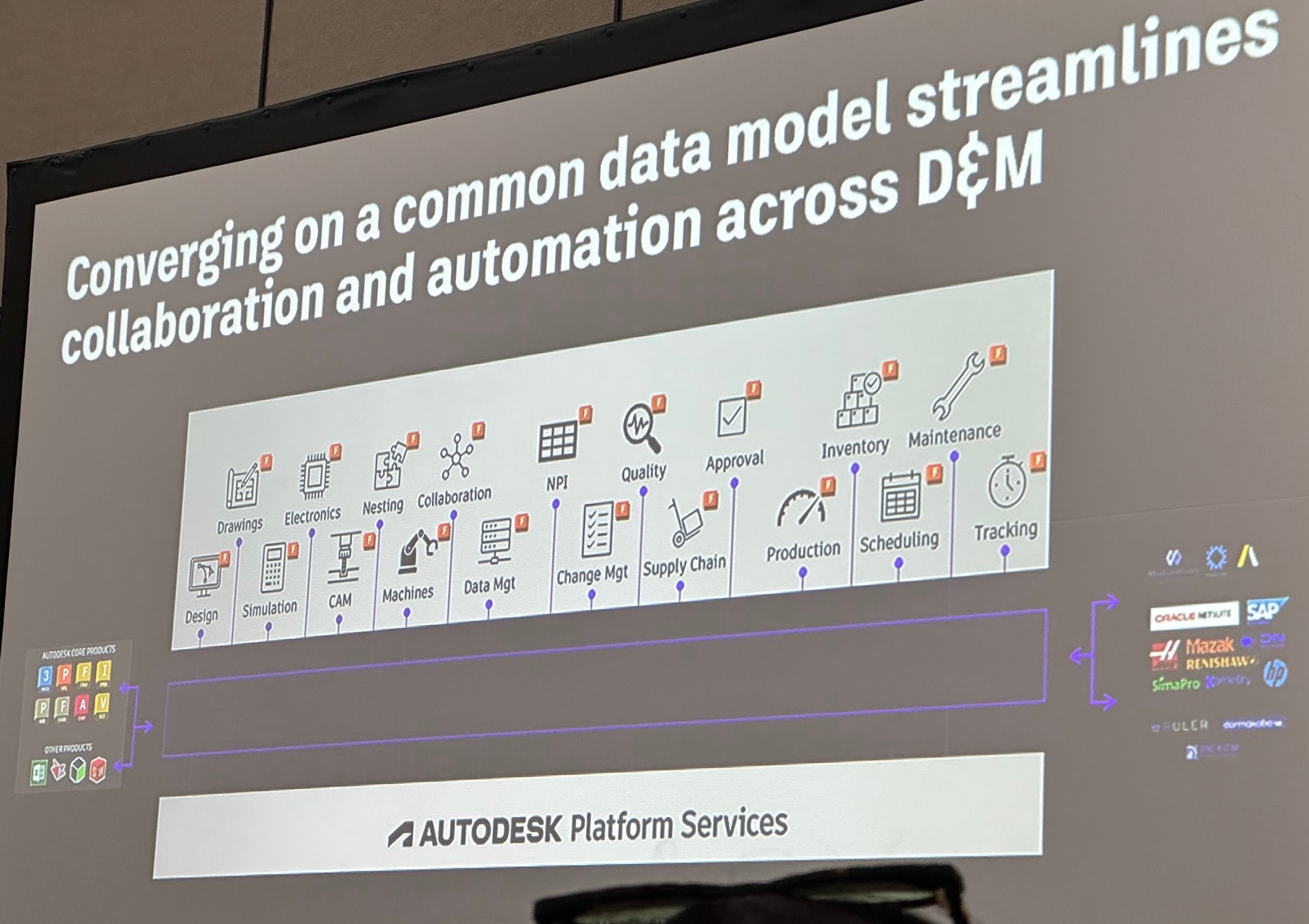

One of the major themes of the keynote was how manufacturers can connect data across systems to eliminate silos and create a unified digital thread. Autodesk speaks about how data can be unlocked and instead of living in different file formats live in a digital thread that spans the entire lifecycle—from design, to production, to construction. This integrated flow of data is critical to enabling digital transformation. And Autodesk Fusion platform is a strategy to make it happen.

The importance of connected data cannot be overstated. In fact, the entire premise of digital transformation relies on breaking down silos, so that data can be connected and flow freely and be used efficiently. This enables companies to streamline their operations, allowing for faster and more flexible manufacturing processes.

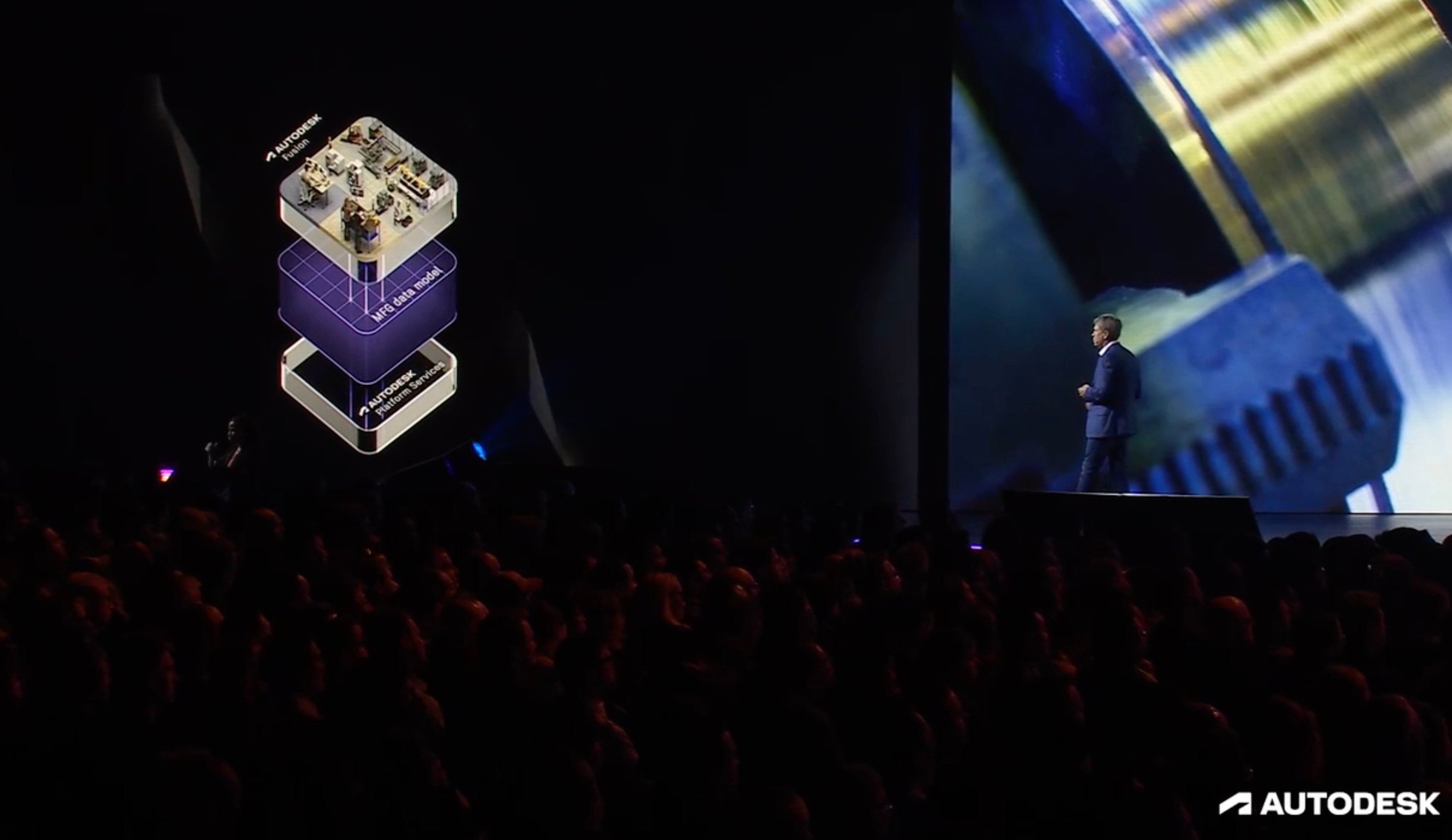

Autodesk’s approach is to perform a series of incremental improvements. The foundation of the platform is Autodesk Platform Services (APS). With unified data model and granular MFG Data Model and other data models, Autodesk is growing its capabilities to manage information in a centralized form. It’s not about one giant leap but rather small, continuous steps driven by connected data and AI.

Autodesk Fusion: Revolutionizing Industries with a Data-Driven Approach

Fusion is positioned as the key of Autodesk’s manufacturing strategy. The platform connects design, manufacturing, and simulation into a cohesive environment, allowing data to be shared across multiple companies and departments. This collaboration is key for driving efficiency, enabling innovations like digital twins—virtual models that mirror the physical product.

These digital twins are becoming foundational in industries that require real-time data to make smarter decisions. The digital twin, combined with a connected digital thread, serves as the launchpad for AI-driven innovations. As data sets are gathered and analyzed across various stages of product development and operations, AI can generate new insights that wouldn’t be possible otherwise.

In the long term, Autodesk’s strategy of coupling digital twins with AI will become a critical aspect of their broader vision for innovation.

Data Utilization: An Untapped Opportunity

Derrek Cooper, VP of Cloud Data and Process Lifecycle Management shared an interesting statistic: 68% of the data companies generate is unused. This represents a massive untapped opportunity. Connecting, organizing, and using that data is where real power lies, and Autodesk’s Fusion platform is designed to facilitate this transition.

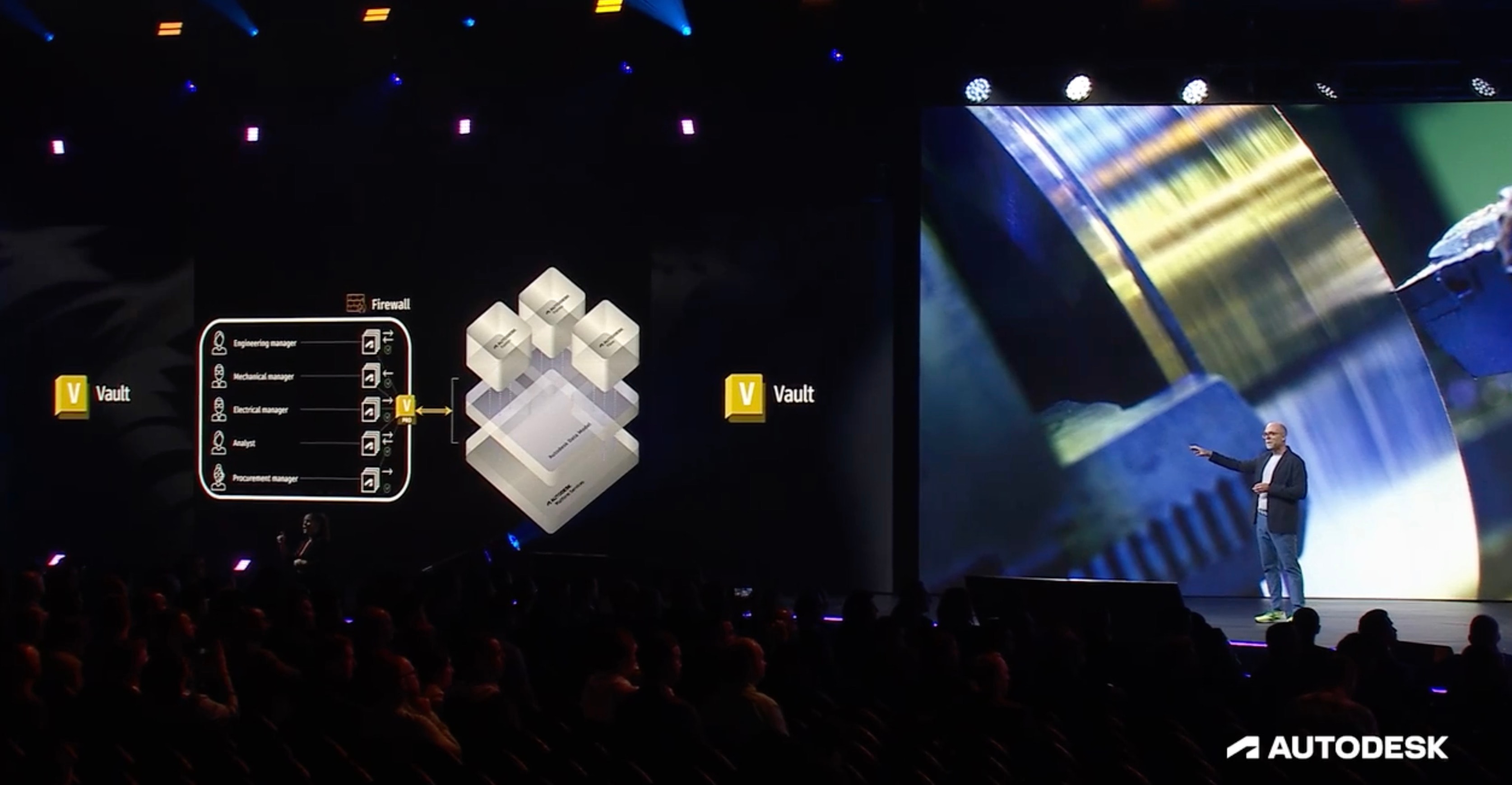

Autodesk is focusing on creating solutions that connect and utilize data more effectively. The Autodesk Vault, for example, can now connect seamlessly with Fusion 360 via the Autodesk Platform Services (APS).

This means that data can flow from one system to another, creating a strong foundation for future innovation. Autodesk emphasized future development of Autodesk Vault web enablement allowing to share data with everyone using Web APIs

This integration is not just about connecting Autodesk’s existing products; it’s about building a future-proof platform for data management and AI capabilities.

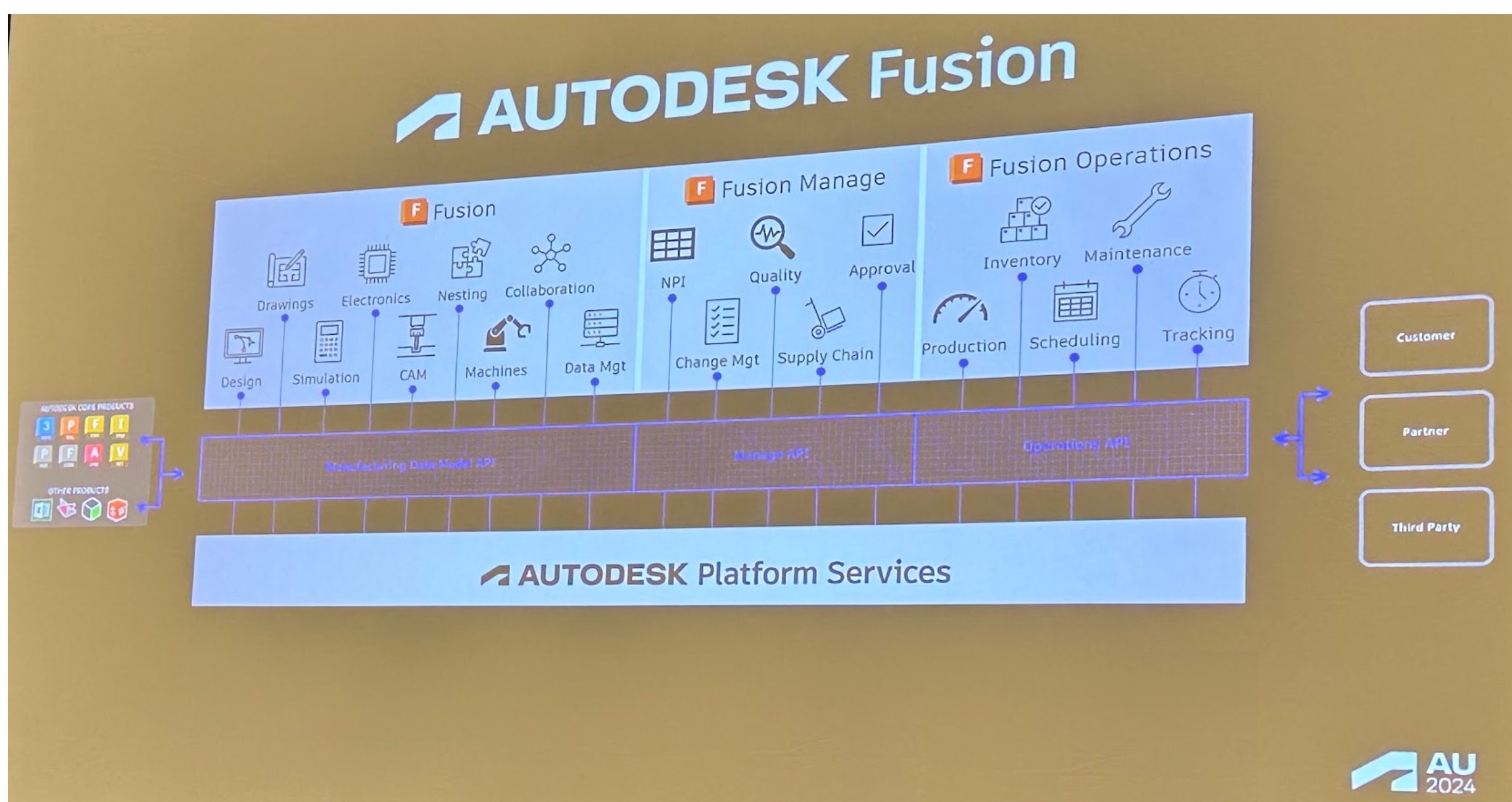

The PLM strategy of Autodesk includes combining Fusion platform, Fusion Manage and Operations services. I captured following slides from PLM Summit and Data Management roadmap.

The new foundation of strategic PLM and data management development includes building unified data layer on top of APS covering multiple models with the core MFG Data Model.

The Role of AI in Accelerating Design and Manufacturing

Steve Hooper, VP of Design and Manufacturing Cloud Solutions spoke about the future role of AI, particularly its ability to drive innovation by speeding up design processes. AI tools, such as those embedded in Autodesk Fusion, allow for more rapid iteration and expansion of ideas, particularly in design.

Autodesk has been actively integrating generative AI into its platforms, allowing users to accelerate the creation of new forms and structures. A few notable enhancements that were mentioned include:

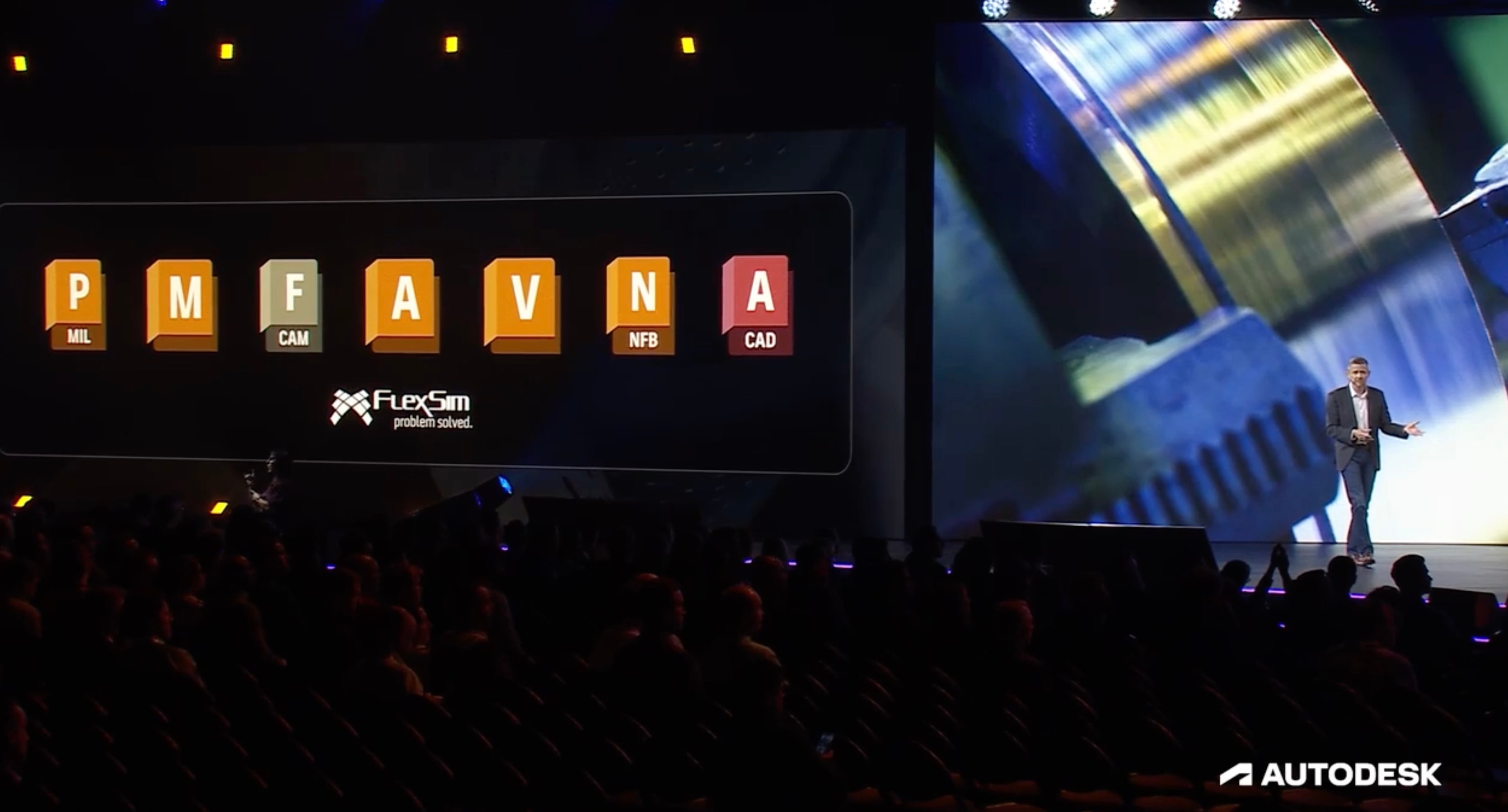

- NOVASTA acquisition: Autodesk’s move to integrate NOVASTA strengthens their AI capabilities across the Fusion platform.

- MakerSite integration with Inventor: This partnership enhances materials intelligence and sustainability analysis during product development.

- Paperless Parts integration with Fusion: This enables manufacturers to quote parts more efficiently by automating costing and streamlining communication between designers and individual shops.

These partnerships and acquisitions are steps toward creating a more powerful and integrated ecosystem for innovation, helping companies optimize their processes and innovate faster.

Tool Enhancements for Better Collaboration and Performance

Autodesk also introduced several enhancements in Inventor and Fusion that improve tool performance and collaboration capabilities. Fusion’s support for electronics design and simulation, along with its integration of mechanical and electronic systems. The ability to collaborate across these domains within one platform simplifies the development process and reduces errors.

Further, Fusion’s AI tools—such as sketching constraints, generative dimensions, and integrated CAD capabilities—continue to push the boundaries of what’s possible in design.

These tools not only enhance the design process but also improve collaboration, enabling teams to work more efficiently.

Autodesk AI is a foundation of automation in drafting and other capabilities

My Reflections on Autodesk’s Design and Manufacturing Strategy

Autodesk’s strategy is focused on creating a fully integrated platform where data becomes the backbone of innovation. By connecting cloud and desktop tools such as Inventor and Fusion 360, Autodesk aims to enable collaboration across mechanical, electronic, and even architectural disciplines.

The integration of Autodesk Vault with Fusion via the APS is a signal that Autodesk is committed to redevelop its data management solutions to be build on top of APS with unified MFG Data Model. This connection ensures that users can access and manage data seamlessly across different environments, which will be critical as the industry shifts towards a more data-centric approach.

It was interesting to see how Autodesk made Vault, and existing two decades old product to scale and become available across multiple application boundaries.

At the same time, it brings many questions about how Autodesk will expand and accelerate their unified data management development to cover multiple aspects and product development and digital thread.

Autodesk’s focus on AI and generative design raises questions about the future of data management. As more companies adopt AI tools, the challenge will be to ensure that data remains accessible, flexible, and scalable for all users, from small manufacturing shops to large enterprises.

What is my conclusion?

Autodesk is making significant strides in delivering a connected platform where data, AI, and collaboration converge. This strategy will be key to helping manufacturers meet the growing demands of complexity and acceleration in product development. As Autodesk continues to build on its data-centric vision, it will be exciting to see how the future of design and manufacturing unfolds. Here are my top 3 takeaways from AU 2024 PLM and data management presentations:

- Connected Data: Autodesk’s Fusion platform goal is to break down silos and enable seamless data connectivity across the product lifecycle.

- Incremental Transformation: Digital transformation is a journey of continuous improvement, expanding of data models and APIs with the foundation of MFG data model and product graphs with each step driven by data and AI.

- AI and Data Are the Future: Generative AI, combined with digital twins and connected data, will be central to driving future innovation.

Autodesk’s approach to data management, AI, and collaboration has the potential to reshape the landscape of design and manufacturing applications. I’m looking forward to seeing how they execute on this vision.

Just my thoughts…

Best, Oleg

Disclaimer: I’m the co-founder and CEO of OpenBOM, a digital-thread platform providing cloud-native PDM, PLM, and ERP capabilities. With extensive experience in federated CAD-PDM and PLM architecture, I’m advocates for agile, open product models and cloud technologies in manufacturing. My opinion can be unintentionally biased.