In the previous article, Rethinking Change Management: Orchestrating Complexity Across Systems & Disciplines, Part 1: Collaborative Workspace, I explored how the modern landscape of product lifecycle management (PLM) demands collaborative environments that can handle complexity across diverse disciplines. PLM methodologies have evolved to encompass various teams across the entire organization, including customer service, marketing, and sales, to enhance productivity and responsiveness.

In a few examples, I demonstrated how traditional change management, which focuses on file check-in/check-out and is largely derived from file-based change operations, is becoming inefficient. New technologies and approaches, such as “collaborative workspaces,” offer more efficient solutions. These innovations help manage data and change processes more accurately, prevent bottlenecks, accelerate the speed of change, and enhance impact analysis during the change process.

I want to connect the evolving concept of single source of truth to the modern approaches in change management. There are a few article to mention before related to the discussion about single source of truth (SSOT). I think those are important to see a broader picture change management evolution. Here are some of them.

The Variable Source of Truth in PLM by Jos Voskuil

PLM single source of truth evolution and data management (Beyond PLM)

Evolution of Single Source of Truth: From Files and Folders to Product Knowledge Graphs (Beyond PLM)

From a Monolithic PLM Landscape to a Federated Domain and Data Mesh by Yousef Hooshmand

I want also to mention the following Share PLM podcast where Yousef Hooshmand speaks about evolution of change control and the concept of single source of change (I will use it later).

SharePLM Podcast Episode 6: Revolutionizing PLM: Insights from Yousef Hooshmand

In my article today, I want to dig more and discuss the next critical component of modern change management: evolving the Single Source of Truth (SSOT) to meet the needs of product development while coordinating across multiple systems, departments, and organizations. I also aim to explore how the new concept of a single source of truth is deeply intertwined with digital transformation and related concepts, such as the digital thread.

Traditional Product Lifecycle Management (PLM) with PDM Roots

A traditional approach in Product Lifecycle Management (PLM) helps companies to manage the entire lifecycle of a product, from its initial concept through to its retirement. This is what you can read in many publications and materials about PLM explaining how supports integration and analysis of data from various sources, including customer feedback, product performance metrics, and market trends, to drive meaningful improvements and innovations. By leveraging PLM software solutions, organizations can maintain a common record of enterprise product data, such as parts and material requirements, engineering changes, workflows, and regulatory compliance. This centralized repository of product data facilitates seamless collaboration among teams, ensuring that all stakeholders are working with the most up-to-date information. As a result, PLM enhances efficiency, reduces errors, and accelerates the product development process, ultimately leading to more successful product lifecycles.

While everything I said above was mentioned many times, the reality of many manufacturing companies that such an idealistic picture relies on a specific concept of a “single source of truth”. Behind such a fancy word, traditional PLM system holds a “single SQL database” to become a single repository of the product data.

The approach of a single repository goes back to a traditional MCAD driven PDM system that stored files and metadata in that database. With a growing complexity of products and processes such an approach is quickly becoming outdated. A combination of multiple systems mechanical design, electronics, software brings questions about organization of the data distributed in multiple systems. Even more, each modern CAD system (MCAD, ECAD, etc) comes with its own “data management” solution and separate design changing process.

The Limitations of Traditional Product Lifecycle Management SSOT

The concept of a Single Source of Truth (SSOT) has long been defined as the key element of effective PLM and change management. By centralizing product data, SSOT promises consistency, traceability, and efficiency. However, as products become more complex, more teams are involved, people are working in different time zones, traditional SSOT models face significant challenges. Here are limitations of traditional SSOT model:

- Complex Data Structures: Many SSOT implementations rely on rigid, file-driven hierarchical data models that struggle to accommodate complex relationships represented in multiple systems and coordinate changes using traditional check-in/out process

- Siloed Change Implementation: Even within a centralized system, data silos persist when SSOTs are isolated within specific domains (e.g., MCAD, ECAD, ALM, ERP, MES, and others).

- Limited Interoperability: While interoperability between system exists, it is often limited to simple “syncs” when some subset of the data from one system is “copied” to another system. It creates many “sync” processes with the lack of robust mechanisms to control what part of the data is going under the change and how to prevent data goes out of sync in the process of change approvals across the digital thread.

- Change Complexity: Managing changes across systems and disciplines often reveals gaps in preserving a SSOT (database) implementations, where asynchronous updates and disconnected workflows result in errors and complex conflict resolutions based on the events happening in multiple systems.

In multiple conversations with engineering and manufacturing teams, I discovered challenges in creating a cohesive and transparent change management process to coordinate changes and approvals.

To address these limitations, the SSOT concept, originally developed in the 1990s for MCAD-based PDM systems, must evolve from a file-driven product structure to a modern, dynamic data model and collaborative workspace.

Engineering Change Management Evolution

Engineering Change Management (ECM) is an important component of Product Lifecycle Management (PLM) that focuses on managing changes to a product’s design, manufacturing process, or documentation.

Here is a traditional model of ECM process. It typically begins with identifying the need for a change, followed by the creation of an Engineering Change Request (ECR). This request is then reviewed and approved by a Change Control Board (CCB), which ensures that the proposed change will not negatively impact the project timeline or costs. Once approved, the change is implemented and communicated to all relevant stakeholders.

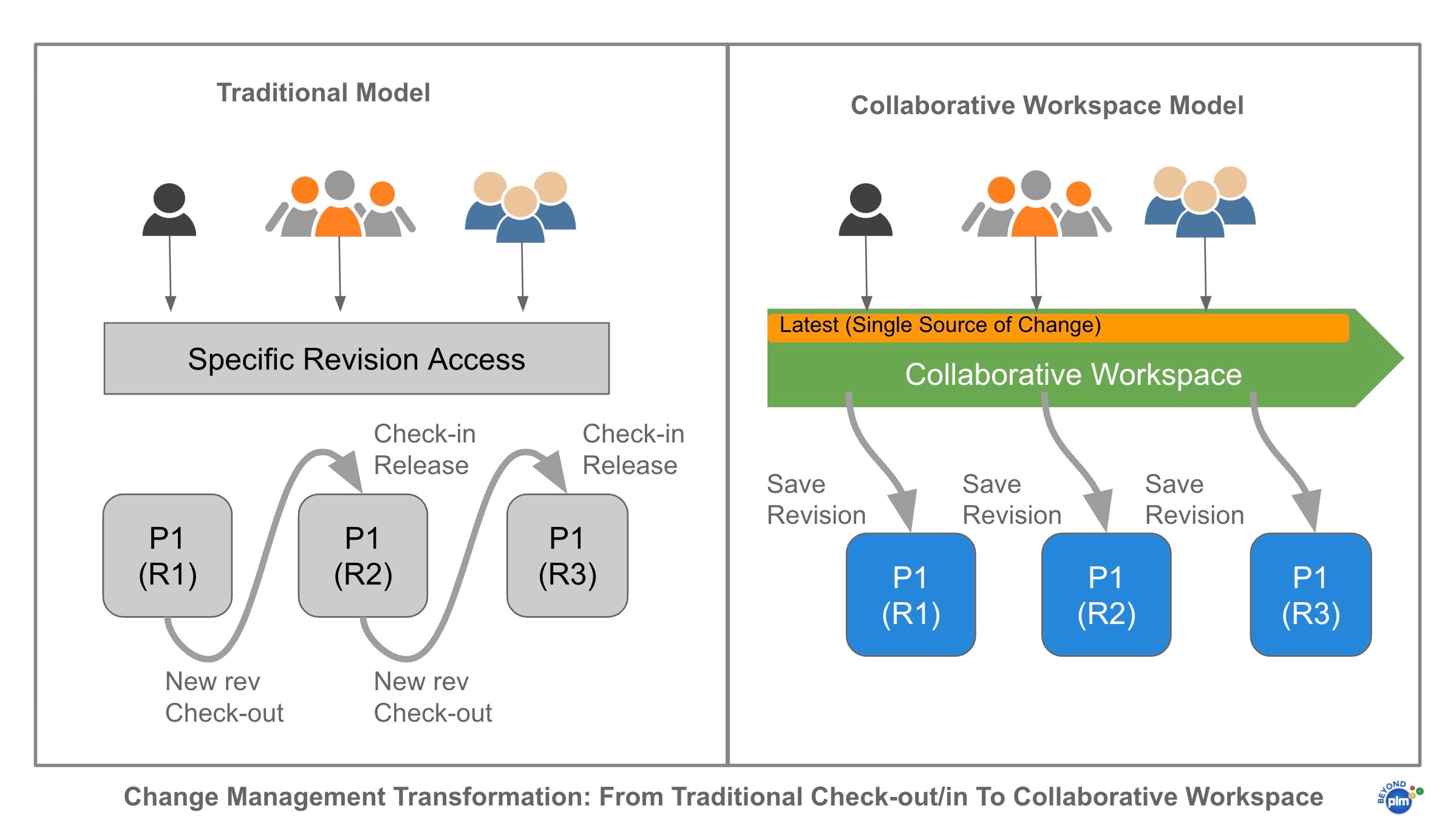

A traditional mechanism of change management, creates a revision (often during the check-out process), which then allow to perform changes (eg. in CAD design) and then confirming the change using check-in process. The complexity of coordinating between multiple systems and disciplines makes this process very complex and hard to synchronize. Each system independently might be responsible for changes of a specific subsystem, assembly, or components allowing to control a single specific change. A collaborative workspace approach can help to bring all these changes together for review and approvals.

Collaborative Workspace with Shared Data Model as the Single Source of Change

The Collaborative Workspace, as introduced in the first part of this series, plays a role of collecting information between teams and users and manage “best so far” or “latest” representation of the product information. Such a workspace technically represents a virtual single source of truth while multiple systems (eg. each CAD PDM or other systems, or even a user) control changes of individual elements. A collaborative workspace can manage role-based access to allow to all data to be presented in a cohesive way, but changed only by specific users or systems to support a single source of change (for example a geometry can be changed only by cloud CAD/PDM system connected to this workspace). At the same time, a collaborative workspace provides a shared environment where stakeholders can collaborate in real time before an approval of change happens and a baseline is saved.

Here are benefits of the approach:

- Centralized access to the latest data and change candidates

- Transparent workflows that capture the rationale behind changes

- Cross-disciplinary participation in change reviews and approvals

- Real-time updates synchronized across all connected systems

This unified approach bridges the gap between the siloed systems with traditional change management processes (eg. check-in/out) but also integrated online with new cloud-based CAD/PDM systems. Changes initiated in the Collaborative Workspace are instantly propagated through the federated data model representing SSOT, ensuring consistency and traceability throughout the product lifecycle.

Modern SSOT & Change Process Using Collaborative Workspaces

A collaborative workspace approach is capable of integrating data from multiple systems and teams using a concurrent asynchronous mechanism. It must support federated data modeling, enable multiple team members to review data in real time with contextual relevance to product features, designs, and requirements, and facilitate coordinated and connected decision-making and approval processes across teams. Here are main characteristics of this new approach.

Flexible and Contextual Data Models

An evolved SSOT recognizes that different stakeholders require different views of the same data. Engineers, manufacturers, and supply chain professionals need tailored representations to work effectively. Contextual data models enable tailored representations that simplify complex datasets and enhance product development processes. Contextual data models enable:

- Multiple engineering disciplines (mechanical, electronics, software)

- Multiple data model representations (e.g., EBOM, MBOM, SBOM) linked by a common data model.

- Role-specific views to control data access by group of people

- Advanced querying and filtering to slice and dice the information (eg. where used query, flattened rollups, dependencies analysis, etc.)

Collaborative & Federated Change Architecture

Rather than centralizing all data in a single system, a federated SSOT connects multiple systems and data sources while maintaining a unified view of the product’s lifecycle. This approach leverages graph-based data models to dynamically link objects and attributes, enabling:

- Real-time changes across multiple data elements done by multiple users simultaneously

- Cross-disciplinary data visibility and asynchronous updates without the need to lock the structure for synchronization

- Seamless integration with existing tools and platforms both file based and cloud-based services (eg. CAD, PDM, ERP, Supply chain)

Baseline Traceability and Revision Control

In the new paradigm, the core revisioning (baseline) change management process occurs once the information is collected, reviewed, and validated by multiple users and teams. Such a process allows to “snapshot” the data into micro-changes and organize a granular data representation that can be referenced for tracking history and revisions. The granularity of baselines can be different and dependent on the lifeycle type (eg. file based change and item based change can be different, minor and major revisions can be used, effectivity specific changes can be captured using flexible and contextual data model.

Baseline change mechanism allows the following functions:

- Granular baselines for each data objects (eg. item, assembly, file, etc.)

- Change propagation bottom up and top down in product structure to support revision interchangeability

- Revision data structure visualization and comparison

- Manual and automatic conflict resolution

The following picture illustrates the transformation from direct revision control via check-in/out and new revision process to collaborative workspace.

Digital Thread and Supply Chain Collaboration

These two topics are becoming extremely important for model complex products and manufacturing environment. Supply Chain Collaboration is more critical than ever. PLM solutions enable supply chain partners to collaborate in real-time, sharing product data and design information to ensure that all stakeholders are aligned and working towards the same goals.

The evolved SSOT is not just a repository; it is a critical enabler of the digital thread organization and supply chain collaboration. Combined with multi-tenant architecture and flexible data model to support federated links, this approach allows to linking every stage of the product lifecycle—from requirements to design, manufacturing, and service—the SSOT provides the backbone for:

- End-to-end traceability.

- Enhanced decision-making through real-time data access.

- Collaboration across supply chains and the partner ecosystem.

By providing a robust and flexible data model a collaborative workspace allows to share product data in a real time to facilitate seamless communication and coordination among manufacturers and their supply chain partners. This collaborative approach not only reduces errors but also enhances overall performance, enabling organizations to respond more quickly to market demands and deliver high-quality products to their customers.

What is my conclusion?

The evolution of the data management technologies and introduction of collaborative workspace representing a novel change management approach can simplify the process of capturing and controlling changes in complex engineering and manufacturing data structures. Collaborative structured data model used for real time collaborative process to capture all changes done by multiple applications and users represents an approach where all changes can be captured and coordinated in real time. This process replaces an old traditional method which is based on revision driven operations such as check-out/in with the need to perform simultaneous changes in multiple systems (eg. multiple CAD designs, complex multi-disciplinary system, contract manufacturing and other use cases)

By introducing a federated, contextual, and collaborative PLM change management software, organizations can transform their change management processes into a seamless, collaborative experience that accelerate change process and improve efficiency. By anchoring the SSOT in a Collaborative Workspace, businesses can ensure that multiple changes performed by different people and multiple sources of changes are fully integrated, transparent, and adaptable to the complexities of today’s digital environment.

In my next article about Rethinking of Change Management, I will explore how collaborative workspace approach is capable to connect multiple structures with new changes connected to previous revisions and how files and existing CAD/PDM software can be integrated with a modern Collaborative Workspace approach. As we look forward to your comments and feedback, I want to learn what best practices and techniques you use for solve complex change management scenarios using different technological approaches.

Just my thoughts…

Best, Oleg

Disclaimer: I’m the co-founder and CEO of OpenBOM, a digital-thread platform providing cloud-native PDM, PLM, and ERP capabilities. With extensive experience in federated CAD-PDM and PLM architecture, I’m advocates for agile, open product models and cloud technologies in manufacturing. My opinion can be unintentionally biased.