In this fourth installment of the “Rethinking Change Management” series, we dive into the technical architecture and workflow underpinning a modern collaborative workspace for change management. Building on the concepts introduced in the earlier articles, this piece focuses on the architectural components and a step-by-step workflow that redefines how product data is managed and updated in a collaborative environment. By leveraging advanced technologies and a flexible data model, along with robust document management practices, organizations can scale their change management practices beyond the traditional PDM / PLM check-in/out model.

Review previous articles I wrote in this series of articles.

Why To Rethinkg Product Lifecycle Management (PLM) Change Management

Product Lifecycle Management (PLM) is a strategic business approach that oversees the entire lifecycle of a product, from its initial concept through to its disposal. PLM integrates people, data, processes, and business systems, creating a cohesive product information backbone for companies and their extended enterprises.

However, current PDM/PLM best practices were invented 20+ years ago and rooted back to a traditional PDM services managing CAD files. These days, I can see the need in the invention of a new and holistic approach to manage product information, coordinate between teams and different engineering systems involved into product design and development. An implementation of the new approach includes the following advantages comparing to existing paradigms of PLM and change management.

- Improved Collaboration and Communication: new approach facilitates seamless interaction among teams and stakeholders, breaking down silos and fostering a collaborative environment.

- Increased Efficiency and Productivity: By streamlining product development and manufacturing processes, new change management uses new mechanisms to help users to work faster and boosts productivity.

- Better Decision-Making: Access to accurate and up-to-date product information enables informed decision-making, reducing errors and improving outcomes. New data management capabilities including product knowledge graph, queries and analytics bring new perspective in the decision making.

- Reduced Costs and Improved Profitability: Providing a holistic product data representations (unlike design siloes), the new change management process can support better change reasoning with cost and supply chain optimization impacting directly design and manufacturing operations.

Key Elements of the Collaborative Workspace Architecture in Product Lifecycle Management

The following five architectural components form the foundation for implementing change management processes in a collaborative workspace:

- Databases and Polyglot Persistence Architecture A multi-database approach ensures optimal storage and retrieval of diverse data types. Polyglot persistence allows the system to leverage relational, graph, and document databases based on the specific requirements of the data being managed.

- API and Integration Services These services provide seamless connectivity between the collaborative workspace and other enterprise systems, including CAD, ERP, and legacy PDM/PLM systems. They enable data sharing and synchronization across platforms, ensuring consistency and traceability.

- Data Model and Product Knowledge Graph The Product Knowledge Graph is a flexible and scalable data model that captures the complex relationships between components, assemblies, and associated metadata. Its graph-based structure ensures adaptability to evolving data and workflows.

- Collaborative Workspace A dynamic environment where users interact with shared data in real-time. This workspace allows multiple users to contribute simultaneously, applying changes to the product data without locking others out. Think of it as a “Google Doc” for product data management. This environment facilitates the integration of engineering data, allowing for real-time updates and collaboration.

- Workflow Services These services handle the routing and approval mechanisms, enabling structured and ad-hoc workflows. From simple routing for approvals to complex processes involving multiple stakeholders, workflow services provide the backbone for managing change requests and approvals. These services support engineering change management by ensuring built-in governance and traceability.

Sample Scenario To Explain How Collaborative Change Management Process Can Work

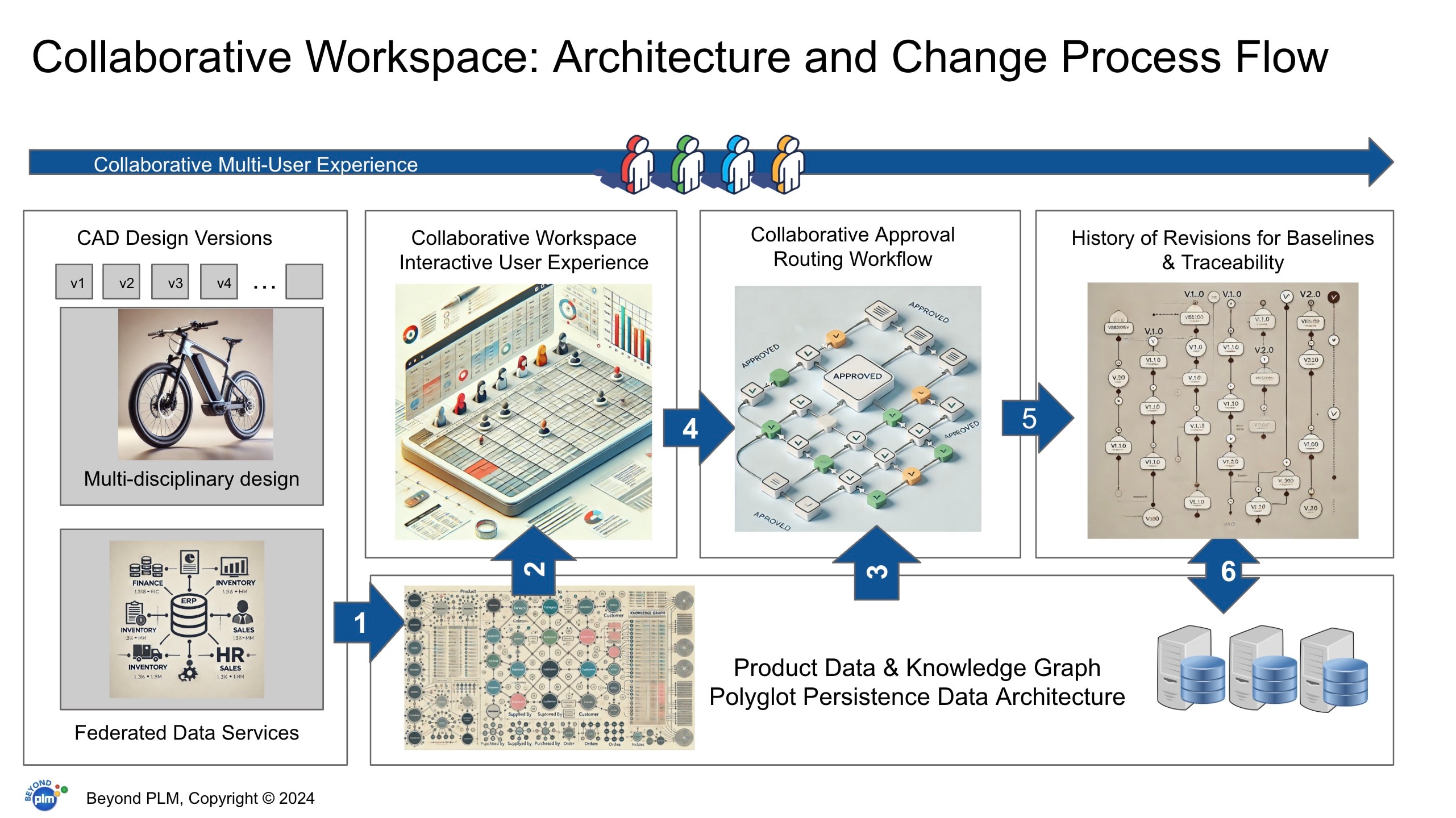

To explain more in details the entire process, I draw the following diagram that can demonstrate new collaborative change management process and how all pieces fit together.

Below is a six-step workflow scenario illustrating how the collaborative workspace supports change management processes.

- Sharing and Retrieving Design Data

- Users can retrieve design data, engineering data, and all product related data from various sources, such as CAD files with version control, cloud-based CAD platforms, traditional PDM systems, or modern design management solutions.

- This step ensures all relevant data is available and up-to-date for collaborative work.

- Integrating design and engineering data is crucial to make informed design decisions that align with sustainability goals.

- Forming a Product Data Representation

- Data is structured into a Product Knowledge Graph (PKG), which provides a flexible and comprehensive representation of the product. The future use of PKG will foster AI services to use the data directly from the collaborative workspace to co-develope and improve.

- The graph captures components, assemblies, dependencies, and metadata, forming the foundation for collaborative workflows.

- Exposing Data to a Collaborative Data Space

- The product data is shared in a collaborative workspace where users can propose and apply changes seamlessly.

- Similar to platforms like Google Docs, Figma, Onshape, or OpenBOM, this space allows for real-time collaboration without disrupting other users’ activities.

- Performing Approval Flow

- Changes undergo an approval process, which can range from simple routing mechanisms to sophisticated workflows involving multiple approvers.

- Workflow services ensure that the process is transparent and traceable.

- Saving a Baseline (Revisions)

- Once approved, an immutable snapshot of the product data is saved in the Product Knowledge Graph.

- This baseline includes specific revisions of assemblies, sub-assemblies, and parts, preserving a consistent state of the product.

- Browsing Revision History

- Users can explore the revision history within the Product Knowledge Graph.

- This feature provides traceability and insight into past changes, enabling better decision-making and compliance.

- PLM software provides the tools necessary to track and manage these revisions effectively.

Future of PLM and Lifecycle Technology

The future of PLM technology is both exciting and rapidly evolving, driven by the adoption of new data management capabilities, collaboration, analytics and AI. The new change management approach and rethinking the way companies are managing product data and changes allows to companies to gain better visibility into their products and processes, enabling more informed decision-making based on real-time data.

Key trends shaping the future of PLM technology include:

- Cloud-Based PLM Solutions: The increasing use of cloud-based PLM solutions enhances collaboration and scalability, allowing teams to work together seamlessly from anywhere in the world.

- Integration with Other Business Systems: PLM is becoming more interconnected with enterprise resource planning (ERP) and supply chain management (SCM) systems, creating a unified approach to managing business processes.

- AI and ML Integration: The use of AI and ML to analyze product data is revolutionizing product development and manufacturing processes, leading to smarter, data-driven decisions.

- Digital Thread and Digital Twin: The growing importance of digital thread in product design and development is enabling more accurate information capture and traceability to support better product outcomes.

By staying ahead of these trends and adopting the latest PLM technologies, companies can enhance their competitiveness, reduce costs, and increase profitability in today’s fast-paced and rapidly changing business environment.

What is my conclusion?

The main differentiator of a new change management in a collaborative workspace lies in its ability to enable multiple users to contribute simultaneously to the change process of product information. By eliminating traditional bottlenecks like file check-out/in and locking, this approach speed up product development and accelerates the change management process. Once changes are finalized, an immutable snapshot is saved, preserving the revision for future reference.

This architecture scales change management from simple PDM workflows to managing large, interconnected subsystems of information. The combination of a Product Knowledge Graph, collaborative tools, and robust integration services creates a foundation for agile, efficient, and scalable change management—a critical capability for modern manufacturing and engineering organizations. A PLM system provides real-time access to critical data for various stakeholders, facilitating better visibility, communication, and integration among teams.

Stay tuned for future articles in 2025 – I think the topic will be one of the key topics to speak about new PLM and change management architecture in 2025. Rethinking PLM and change management is an important thing. Most of the systems and approaches we have today was designed back 20-25 years ago. The time for new collaborative systems with advanced and flexible data management capabilities to come. Just my thoughts…

Best, Oleg

Disclaimer: I’m the co-founder and CEO of OpenBOM, a digital-thread platform providing cloud-native PDM, PLM, and ERP capabilities. With extensive experience in federated CAD-PDM and PLM architecture, I’m advocates for agile, open product models and cloud technologies in manufacturing. My opinion can be unintentionally biased.