The 2023 is almost in the books and now it is a great time to share more about what I learned during this year. Most of my focus was spent on continue building and growing OpenBOM. If you haven’t heard about OpenBOM, check it out. The platform has grown to support many small and medium size manufacturing companies, engineering teams and new product development process of larger enterprises. To read more about OpenBOM, you check OpenBOM blog.

Talking to many manufacturing companies and engineers during this year, I gathered a lot of information about how these companies work, what systems they use today, what problems they have and how they try to solve the problems as well as what solutions, services and systems they are looking for.

In my article today, I want to talk about 7 areas related to manufacturing and engineering software. In particular I keep my passion close to the topic of data management and use of data for different purposes. But some of these topics such as education and establishment of the right playbook to implement product data management and product lifecycle management software are so important in the modern state of business systems development, so I decided to share my thoughts and perspective on education and system adoption and implementation methodology of document management systems in manufacturing process and modern PLM software.

PLM Education

One of my fundamental observation of working with engineers and manufacturing companies for the last few years, was a misalignment of existing paradigms of data management and level of education demanded by complex data management software. Here are three important things to keep in mind:

- Status quo: big distance between existing file/folder/spreadsheet/email paradigm and enterprise data management software (PLM/ERP). The first explains the data dilemma and why engineers and manufacturing companies struggle to find a time for data management.

- Enterprise software such as product lifecycle management (PLM software) and various ERP/MRP systems focusing of supply chain, process management and business processes remain insanely complex and requires strategic planning, heavy IT and services to get them up to speed to organize an entire product lifecycle and integrated data sharing.

- The complexity of modern product development is continue to grow and hit engineering and manufacturing team by the need to manage complex data about products (mechanical, electronics, software, systems). Engineers and companies struggle to get themselves organized with data without significant help from outside.

Altogether, education is very much demanded in all places starting from how to build a strategy for data management and digital thread and ending up with organizing processes and finding ways to streamline collaboration and communication.

Today, most of companeis think about data management as either files/folders/mails or complex enterprise system. What can help here is to focus on education earlier in the process, bring materials and classes to schools and educate engineers about importance of data management.

Why PLM playbook is important?

Moving from fundamental education about data management and process organization, I want to come to a more specific things – how to help manufacturing companies to plan strategically about brining PLM solutions and organizing engineering data to change the processes.

The topic caught my attention after I’ve seen so many PLM and other IT solution implementations fail because of the bad strategy and implementation planning. A typical problem I’ve seen is companies “jumping into implementing a solution” without making an alignment between existing processes and systems, not focusing on process improvement and people first before brining system to manage data and changing processes without changing the organization.

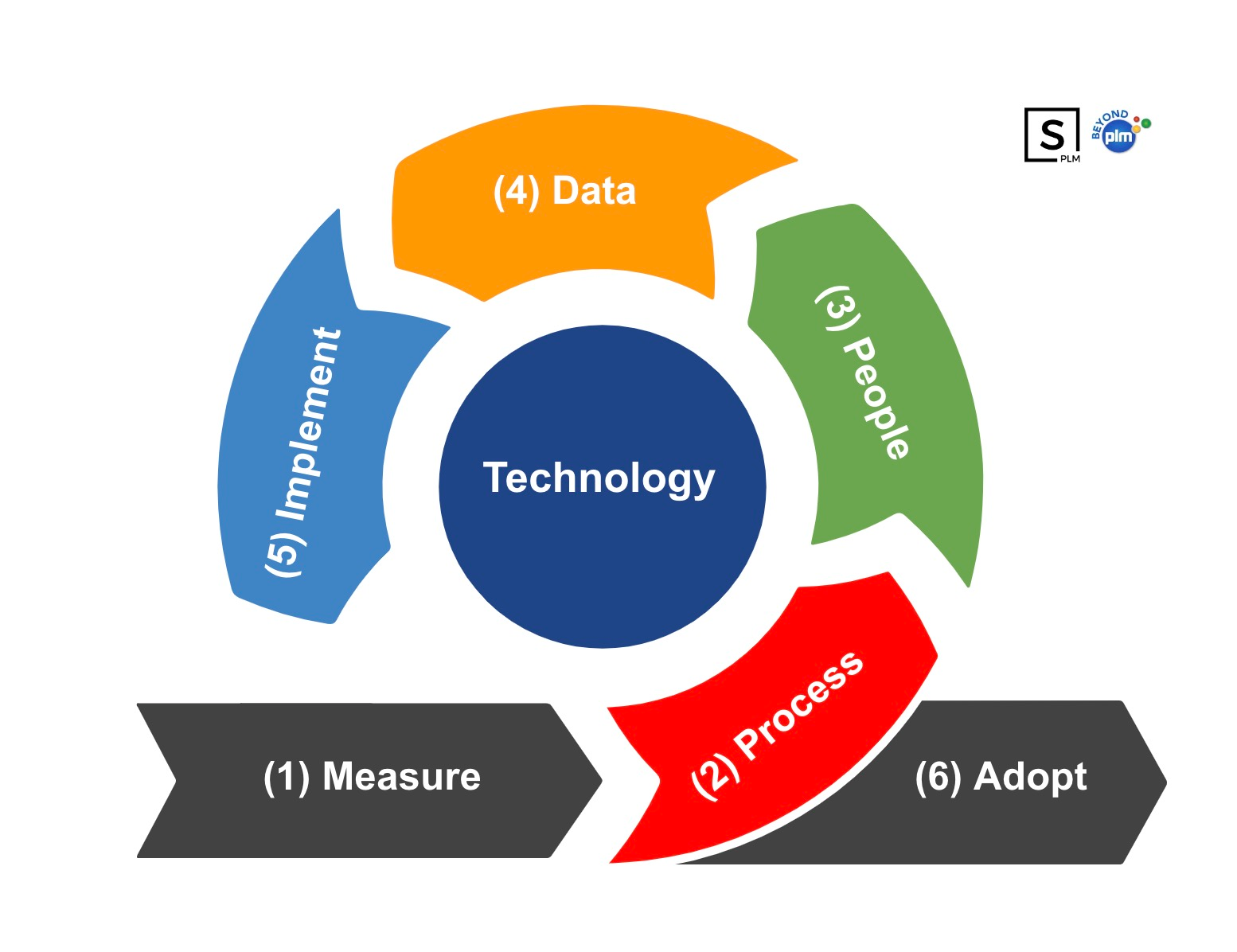

I wrote about it in my article PLM playbook: mastering strategic and tactics for unstoppable PLM implementations. Check the article, it has a few other links you might find useful.

The main point I want to leave you with is that implementation of PLM and other data management systems requires planning that starts before you decide what software to bring to solve it. You should avoid the approach of brining “a solution” before understanding the problem and building a framework that can help you. It includes, analysis of existing manufacturing process (ETO, BTO, CTO, etc), analysis of existing systems, data sources and crafting a plan. Although a technology plays a central part in making all these things happen, software alone won’t help you much and ofter will make your life even more complex. I’ve seen companies implementing expensive PDM systems just to discover that it is not what they are looking for.

Will “free PLM” make a powerful comeback using AI?

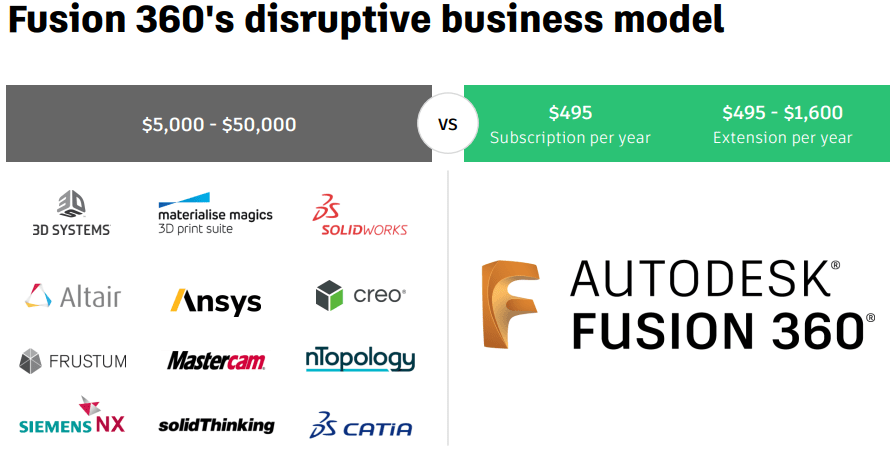

The story of a free software is interesting. Massive adoption of modern business models such as advertising, open source and free software combined with services, was driving a lot of attention for the last 10-15 years in the industries. CAD, PDM and PLM software had some ups and downs in this space. Aras Innovator introduced their “enterprise open source” back in 2007, which was a free download with the ability to develop community software and subscription model. It was a big success , which jumpstarted Aras to large investments from PE firms and led to acquisitions by GI Partners . A few years later, GrabCAD made a splash by gathering a few millions engineers under GrabCAD community umbrella and sold to Stratasys. At certain moment of time, Onshape (later acquired by PTC) was providing Onshape community solution for free. Already after acquisition, Onshape greatly expanded their educational program for free and now also provides Onshape Discover Program free for 6 months. Last, but also very important is Autodesk Fusion360, which was free and still free for many group of users. Autodesk Fusion disruptive business model explains the way Autodesk plan to expand their market presence.

At OpenBOM we provide OpenBOM Design subscription with a free CAD cloud data management for free as well as making our non-commercial and educational subscriptions free.

Industry has mixed feeling about free services and possible ways to monetize them. At the same time, a free service is like water using gravity – always will find a crack to go through. Engineers are continuously looking how to find a free service to use in their practice even tho companies like to pay for software, especially when it comes to the questions of support and business continuity.

Traffic plaid an important role in exchanging a free service for advertising. An interesting question and possible opportunity is to discover how data in the future can provide a source for AI models. Will companies trade a free software in exchange of data and AI?

Files Aren’t Giving Up

A decade ago, cloud CAD and some other software projected the death of files and replacement of files with services and native cloud systems. While, I agree completely with the idea, the speed of projected change is questionable. Although, young generation of users don’t think about “files” as a viable way to manage information and use online systems like Google Docs and many similar, in CAD, PLM, engineering and manufacturing, files are still very legitimate source of information from both work-in-progress as well as release process and downstream operation.

For many engineers, hosted CAD desktop with all familiar features is still preferable compared to a CAD online service and, traditional STEP, PDF, DXF files are still needed in all release and distribution processes for manufacturing planning, contractor work and supply chain. Some of these “preferences” is related to habits and feature richness and some others are part of the regulated and standard processes demanded by companies, contractors and suppliers. The same can be said about beloved “Excel and PDF” files that very often the easiest way to ensure ‘control and ownership’ of the information.

Collaboration and Connectivity

Modern life and business are connected. We stay connected in life and in business. We demand instant information sharing and immediate reactions on our social network messages as well as the information about suppliers’ quotes and customer orders. It is a magical PLM word – collaboration. Collaborative data management, collaborative processes, collaborative PDM and PLM etc. etc. The industry was using this word actively to describe different solutions.

For most companies and teams I was talking to, collaboration and connectivity comes down to a simple capabilities to communicate in the context of work they do and to have an access to the data they need for this work. The changing trend in my view is moving from the large centralized databased to services that are capable to provide an access to the information or perform data changes (ECO/BOM edit), perform tasks (eg. Design review or cost calculations) or focus on a specific process (eg. procurement or part sourcing process)

Old platforms vs new platforms?

There is a growing number of debates about new “cloud-native” systems. According to Gartner, use of cloud-native technologies will be pervasive, not just popular. Gartner analysts said that more than 85% of organizations will embrace a cloud-first principle by 2025 and will not be able to fully execute on their digital strategies without the use of cloud-native architectures and technologies. What does it mean for PLM?

I learned that companies are not necessarily looking how to trade existing old systems for new ones just because of technology. It didn’t happen in CAD centric environments and won’t happen for PLM systems too. Vendors need to offer a fundamentally different transformative way to work. In PLM, it can come as a result of powerful and flexible data management capabilities, flexibility, adaptivity, simplicity or new functions such as, for example, AI capabilities (co-pilot, generative AI, optimizations, analytics).

Large and established PLM software vendors are looking towards vertical integration and “plug-in” new functions to their platforms. New and innovative vendors are more focusing on specialized solutions. At the same time, customers are just looking how to make technologies seamless and painful. The discussions about new vs old systems are getting more specific and granular. Companies are not afraid of solutions that can be connected together (instead of one big platform). I expect future transformation coming to enterprise PLM systems.

How AI will come to engineering, manufacturing and PLM

AI was playing a significant role in business life and systems in 2023. A brutal and broad appearance of ChatGPT was shaken grounds of data management experts and analysts. The questions about “AI contextualization” are everywhere. Every company I speak to is interested in how AI can change current processes and offer a better way to design, generate content, make analysis, and make decision process more effective. However, the first AI solutions will have to solve is to ensure how to build them using customer data and, af the same time, to prevent data from “leaking” outside. Starting from the right data is the key step in building future AI solutions, check for more here. I expect AI to be one of the most interesting topic in 2024.

What is my conclusion?

2023 was an interesting year. I found very interesting to observe how old habits are trying to co-exist with new technological trends and services. In my view, we live in the longest period of time with existing paradigms were stretched to the maximum of what is possible to achieve without applying a significant change in data management principles and the way data and processes are organized. I look forward to 2024 where I expect to grow our understanding how existing legacy PLM systems and habits will be transformed in the new ways of doing business.

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital-thread platform with cloud-native PDM & PLM capabilities to manage product data lifecycle and connect manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.