Summer is a great time to catch up on PLM reading. What is on the top of the mind of manufacturing enterprises these days? Choosing “the right PLM” is still a dominant theme in many publications. It is natural. Companies are looking how to chose the right strategy and bring right tools to implement their PLM strategy and digital transformation? I stumble on many tables and comparisons. What are the tools that can help you to fulfill your PLM strategies. Here are just a few examples of these, but I think they represents the trend.

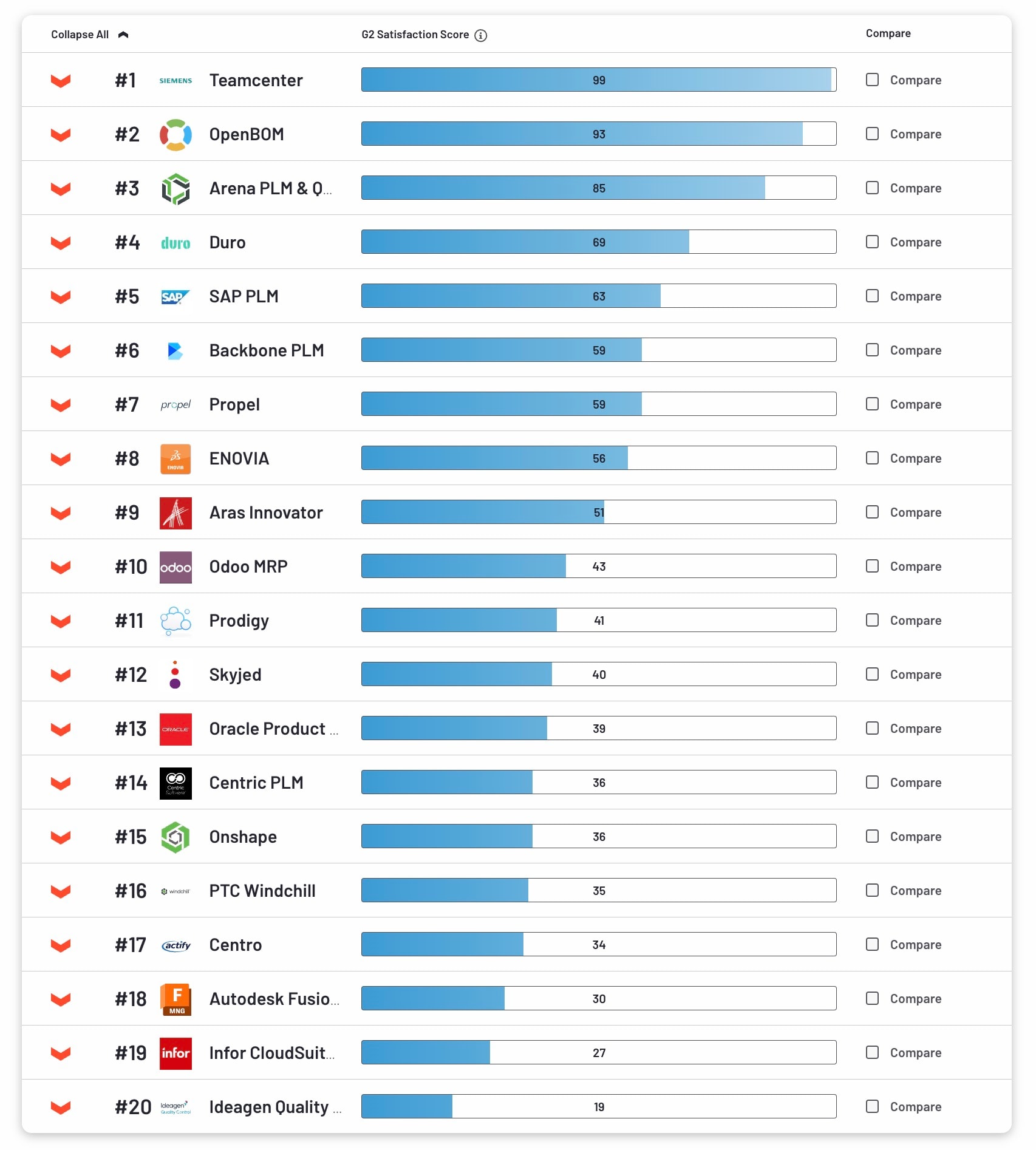

In the social world, everyone looks “who is using what”. A great strategy built by G2 (aka “yelp for business software). You can see PLM G2 ranking more than 60 PLM software product lifecycle products with top 20 PLM solutions for product data management, quality management, document management, production process. While G2 gives you a ranking and helps to make assessment of functions, choosing the right product is not a simple thing. The good thing about G2 comparison is that it ‘socially driven’, which gives you a confidence of independence.

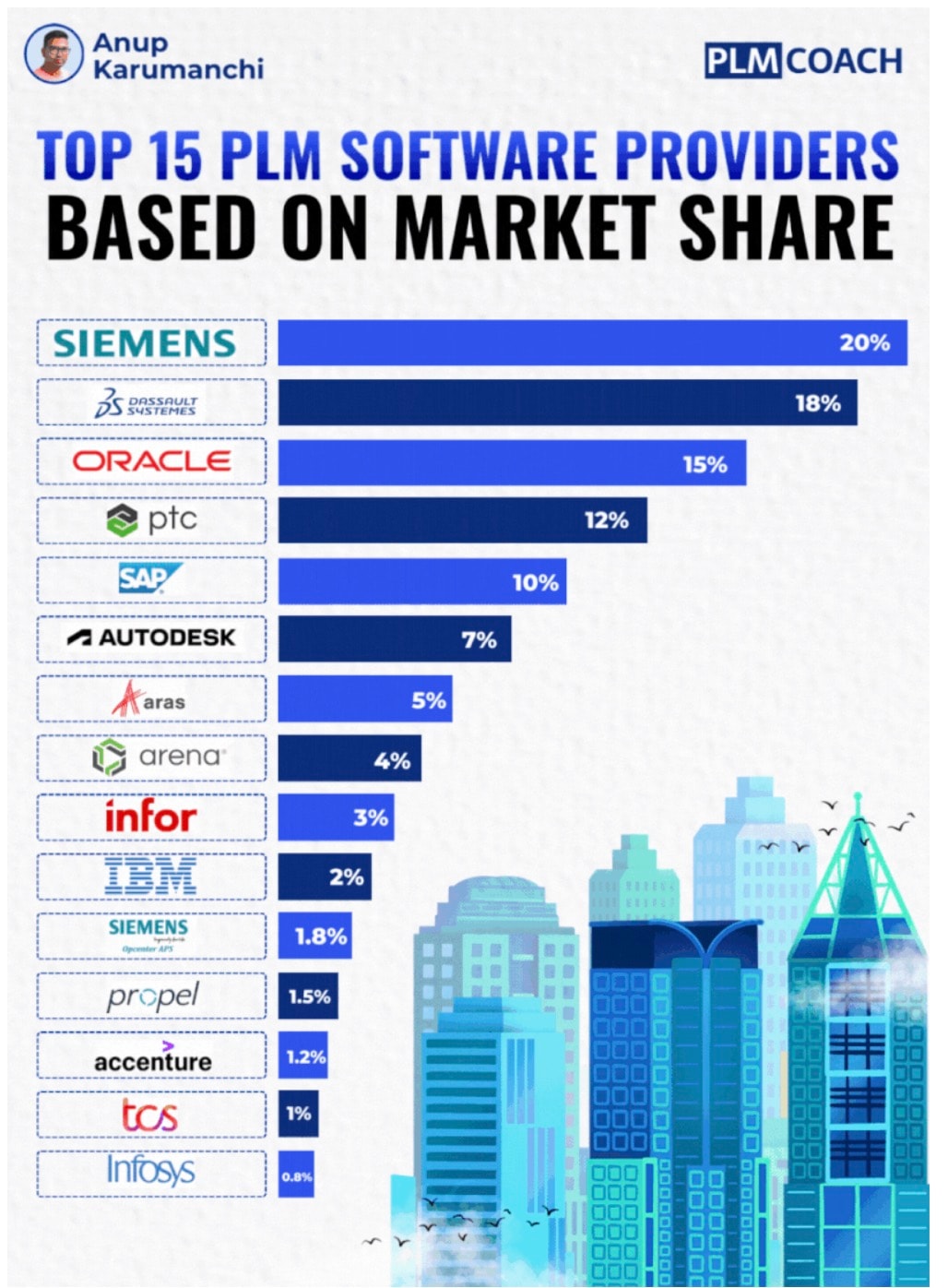

Another angle of comparison is money. Comparing by market share is another approach. Some of these comparisons trigger questions when you attempt to bring known data points and calculate the market numbers top down and bottom up. The holistic approach is needed here. Here is an example I captured from Anup Karumanchi, PLM coach.

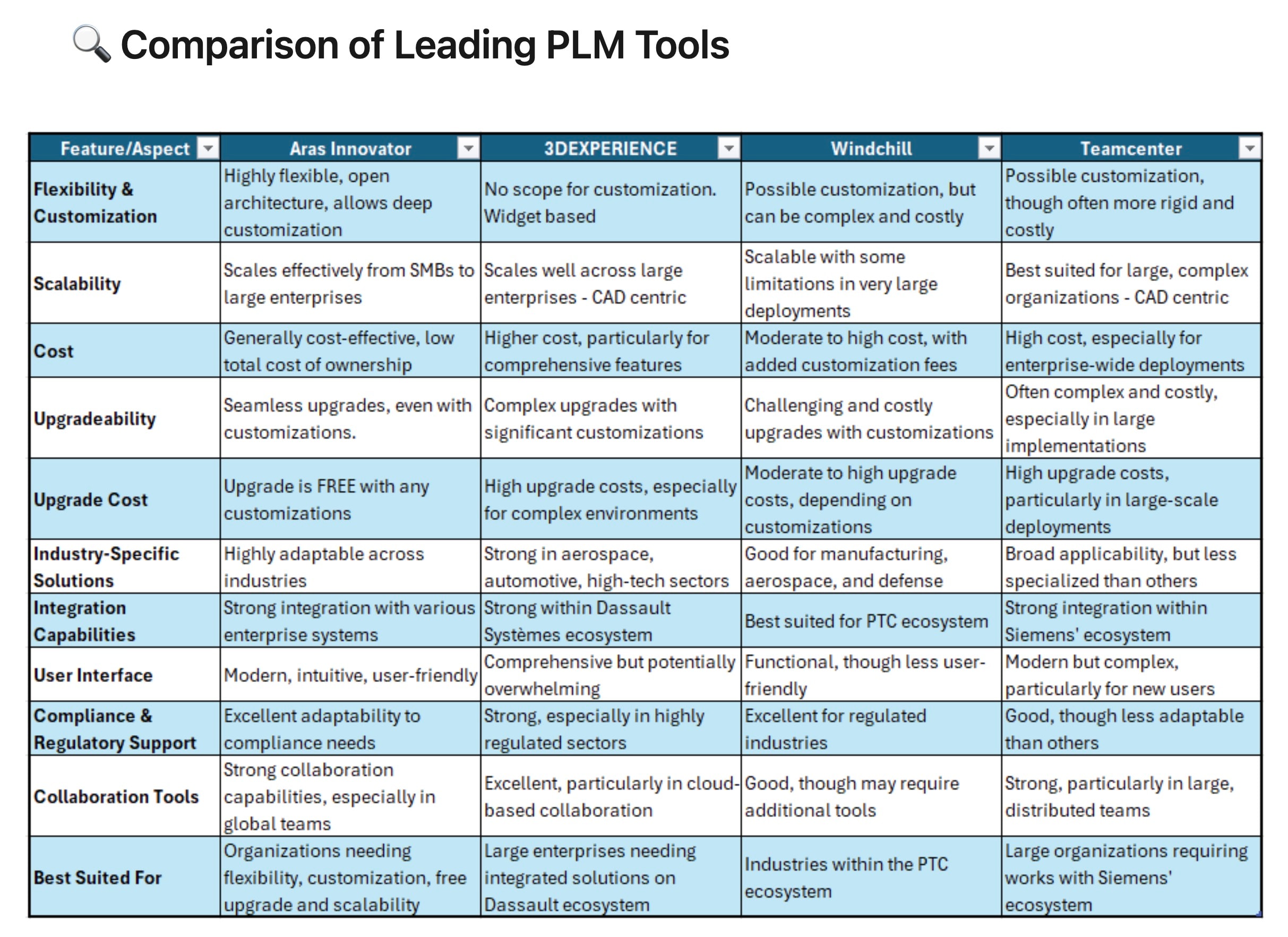

A proven strategy for ages is “to buy from IBM”. It never fails. Therefore, consultants offer comparison of leading PLM providers. Learning from specialists that offer a comparison of tools is another approach. Here is an example of such leading PLM tools comparison offered by Vasant PADHIYAR.

After reading and making analysis of these and other materials, I found that in most of the cases, companies and consultants are offering you how to align your strategy with one or another tool. The next step after selecting the tool is to align all your needs for this tool is almost an inevitable approach.

The quintessence of this comparison so called “Best Suited For” demonstrates, in my view, one of the biggest challenges of PLM industry status quo. Except of “Aras” that good for flexibility (who doesn’t need flexibility), all three others says “best for me”. Basically it says “pick me and your PLM will be all set”.

The thing I found missed in most of these comparison is how a PLM solution is capable to support a specific process in a company. At the same time, each tool provider, especially leading PLM providers are focusing on how to cover the largest “monolithic” scope of functions.

It made me think about possible alternatives and, especially, about the approach that will allow to break the status quo of monolithic PLM software and architectures.

The Status Quo: Monolithic PLM Platforms Trying to Boil the Ocean

In today’s manufacturing landscape, companies need to have Product Lifecycle Management (PLM) systems to manage everything from design and engineering to manufacturing and service. However, many organizations find themselves cornered to monolithic PLM platforms that attempt to do everything—often with mixed results. These platforms aim to cover every aspect of the product lifecycle, promising a one-size-fits-all solution. But in reality, companies use multiple PLM platforms and struggling to find the right way to build a strategy that can use best software based on their business needs. The attempt to bring a single system end-to-end is like a mirage in a dessert that presented nicely on PowerPoint slides, but never really materialized. At the same time, by focusing an entire product lifecycle on a single product lifecycle management (PLM) platform is limiting companies in their strategy of business processes.

Competing PLM platforms often make ambitious claims about their ability to provide comprehensive solutions that can manage every aspect of product development and beyond. They strive to “broad the scope,” covering an extensive range of functionalities—from requirements management and system modeling to BOM management, manufacturing processes, and service operations. The problem? These monolithic systems are often too rigid, limited to their own ecosystem, complex, and slow to evolve, making it difficult for companies to keep pace with changing market demands and technological advancements. While SaaS is a dominant theme in all PLM architectures these days, unfortunately when it comes to leading brands, it means to host the solutions available for years using one of the hyperscalers (for this topic, the question of multi SaaS PLM strategies is becoming critical).

The Reality: Crafting a Domain-Specific or Vertical Strategy

The reality for many companies is very different from the vision sold by monolithic PLM vendors. Organizations are recognizing the need to build domain-specific or vertical strategies that cater to their unique business needs. Instead of relying on a single, cumbersome PLM platform, forward-thinking companies should be looking for ways to develop targeted strategies that address specific areas of their operations, such as BOM management, system modeling, manufacturing processes, contract manufacturing, or supply chain.

This shift in thinking is driven by the recognition that no single PLM platform can effectively manage the diverse and evolving needs of every business. Companies are increasingly focused on creating specialized, modular solutions that allow them to innovate and respond to market changes more quickly and efficiently.

The Need for Functional Services: Unifying Specific Needs

A possible approach to break monolithic approach is to focus on functional services. These services are designed to address particular domains within the product lifecycle, such as:

- Requirements Management: Ensuring that all product requirements are captured, tracked, and met throughout the development process.

- BOM Management: Managing and organizing the Bill of Materials to ensure accuracy and consistency across departments.

- Model Based System Engineering: Enabling complex system designs and simulations to ensure that products meet performance and safety requirements.

- Manufacturing Process Management: Optimizing manufacturing processes to reduce costs, improve quality, and accelerate time-to-market.

- Contact Manufacturing and Supply Chain: Organizing communication and coordination of BOMs and other information with CMs and supply chain activities.

- Service Operations: Managing after-sales service and maintenance to ensure customer satisfaction and product longevity.

These functional services can be tailored to meet the specific needs of each domain, providing a more focused and effective approach to managing the product lifecycle.

Building a Strategy: Switching from Monolithic Architectures to Focused Services

To successfully transition from a monolithic PLM architecture to a more agile, service-oriented approach, companies need to develop a clear strategy. Here’s how to do it:

- Start with Assessment: Evaluate the current PLM system to identify areas where it falls short. Look for opportunities to decouple services and create more modular solutions.

- Prioritize Domain-Specific Needs: Identify the key areas where focused services can provide the most value. Start by decoupling services in these areas and replacing them with more specialized, agile solutions.

- Implement Horizontal Services for Connectivity: As you develop focused vertical services, ensure they can connect seamlessly through horizontal services. These might include data management, collaboration tools, and integration platforms that enable different services to work together effectively.

- Adopt a Phased Approach: Transition gradually, starting with the most critical areas and expanding as the new architecture proves its value. This approach minimizes disruption and allows for continuous improvement.

- Leverage Cloud and SaaS: Consider using cloud-based and SaaS solutions to gain the flexibility and scalability needed to support an agile, service-oriented architecture.

One of the trending approaches is separating SOR (system of records), SOE (system of engagement), and SOI (system of intelligence). This approach allows you to bring a divers set of services connected with existing PLM monoliths without breaking them.

An important outcome of this strategy is to push the reset button on a legacy data management so popular in PLM systems developed back in 1990s and 2000s.

John Gall’s Law: Building a Complex System from Smaller, Simpler Systems

John Gall’s Law states that a complex system that works is invariably found to have evolved from a simple system that worked.

Gall’s Law states that all complex systems that work evolved from simpler systems that worked. If you want to build a complex system that works, build a simpler system first, and then improve it over time.

Check my earlier articles about PLM simplification and Gall’s law. This principle is highly relevant when moving away from monolithic PLM architectures. Instead of trying to build a complex system from scratch, start with smaller, simpler systems that address specific needs and can be integrated over time.

By focusing on creating and connecting smaller, functional services, companies can build a more resilient and adaptable PLM system that evolves naturally and effectively. This approach reduces the risk of failure and ensures that the system can adapt to new challenges as they arise.

What is my conclusion?

The era of monolithic PLM systems is coming to an end. I can see the path forward for manufacturing companies to adopt breakdown of PLM monolithic legacy into manageable set of SaaS (services). The path forward belongs to agile and connected Services

Companies that want to stay competitive must move toward agile, connected services that can address specific needs more effectively and adapt to change more quickly. By building a strategy that focuses on domain-specific services and connecting them through horizontal solutions, organizations can create a more flexible, scalable, and future-proof PLM architecture.

Moving away from a monolithic foundation is not just a technical challenge; it’s a strategic imperative. Embracing an agile approach with connected services allows companies to innovate faster, respond to market demands, and ultimately achieve better business outcomes. The time to make the switch is now.

Just my thoughts…

Best, Oleg

Disclaimer: I’m the co-founder and CEO of OpenBOM, a digital-thread platform providing cloud-native PDM, PLM, and ERP capabilities. With extensive experience in federated CAD-PDM and PLM architecture, I’m advocates for agile, open product models and cloud technologies in manufacturing. My opinion can be unintentionally biased.