The discussion about what is a dominant system in the enterprise has started a long time ago. Historically, MRP, later MRPII and ERP systems established itself as a leaders and positioned as the only system enterprise IT should be concerned of. It was probably true for some time, but already back in the 2000s, the dominance of ERP systems was broken by a strong presence of CRM systems and later by different activities coming from PLM and other domains. While ERP achieved the goal to be ultimate control of all processes starting from finance, the stronghold of ERP as a single source of truth about the product was questioned by many PDM, PLM, and other systems. The old idea of a single source of truth in Product Lifecycle Management (PLM) began with the concept of single data, single application, and single platform. The premise was simple: create software that centralizes data and then expand its capabilities by literally controlling the data.

However, the landscape has changed. Companies began seeking solutions to solve specific problems more effectively than what a single Manufacturing Resource Planning (MRP II) or ERP database could offer. This shift led to the rise of specialized software vendors in Customer Relationship Management (CRM), PLM, Manufacturing Execution Systems (MES), and other areas, which managed to penetrate both large enterprises and smaller organizations. Today, the reality is a multitude of enterprise software and applications coexisting within organizations.

Earlier this week, I wrote an article about integrations in 2024, which you can check out here. While the presence of multiple enterprise software tools is not something that companies are disputing these days, the question about data is an interesting one. One of the trends, I identify in integrations is what I call – Data Centric and Master Data concepts. The concepts and implementations of master data management divided between analytical and operational.

The idea of data centric approach relies on the capabilities of multiple data management technologies to collect, aggregate and make sense of data that present in multiple systems. Here is a passage from my previous article:

This integration pattern is focusing on how to extract data from multiple systems and create a central repository for critical business data, ensuring consistency and accuracy across all systems. Once this repository is built, it can be used for multiple purposes such as data search and navigation, optimizing customer focused tasks in CRM software, concentrating data from many systems in a central ERP system or integrating multiple ERP systems used by a company. This pattern supports better data governance and can help maintain data integrity in complex environments. Technology for such a data centric integrations was evolving from both directions- connecting enterprise systems and developing of global scalable web platforms.

In today’s article, I want to explore the concept of “master data” and explain why it is becoming more critical than ever for manufacturing organizations.

The Shift from Applications to Data

Data is becoming one of the most critical assets for manufacturing organizations. The main factors that helped to this to happen are coming from both technological and business perspective. The technologies are advancing, and with modern cloud computing capabilities, it is not so hard to think about how to aggregate data from multiple systems at a reasonable cost. Data modeling and databases are becoming more and more efficient. The polyglot persistence architecture is contributing to that too – there are so many ways to slice and dice the that using graph databases, vector databases, NoSQL data management systems, and later using AI technologies. From a business perspective, manufacturing companies are moving from selling products to selling

Longevity of Data Over Applications: In enterprise organizations, data often outlives the applications that manage it. This shift highlights the importance of focusing on data management rather than just application management.

Accurate Data for Decision-Making: Accurate data is crucial for decision-making processes. It’s about getting the right data to the right people and organizations at the right time, ensuring informed and effective decisions.

Data as a Source of Analytics and Intelligence: Data serves as the foundation for analytics and intelligence. It is pivotal for the development of future AI applications and systems, driving innovation and efficiency.

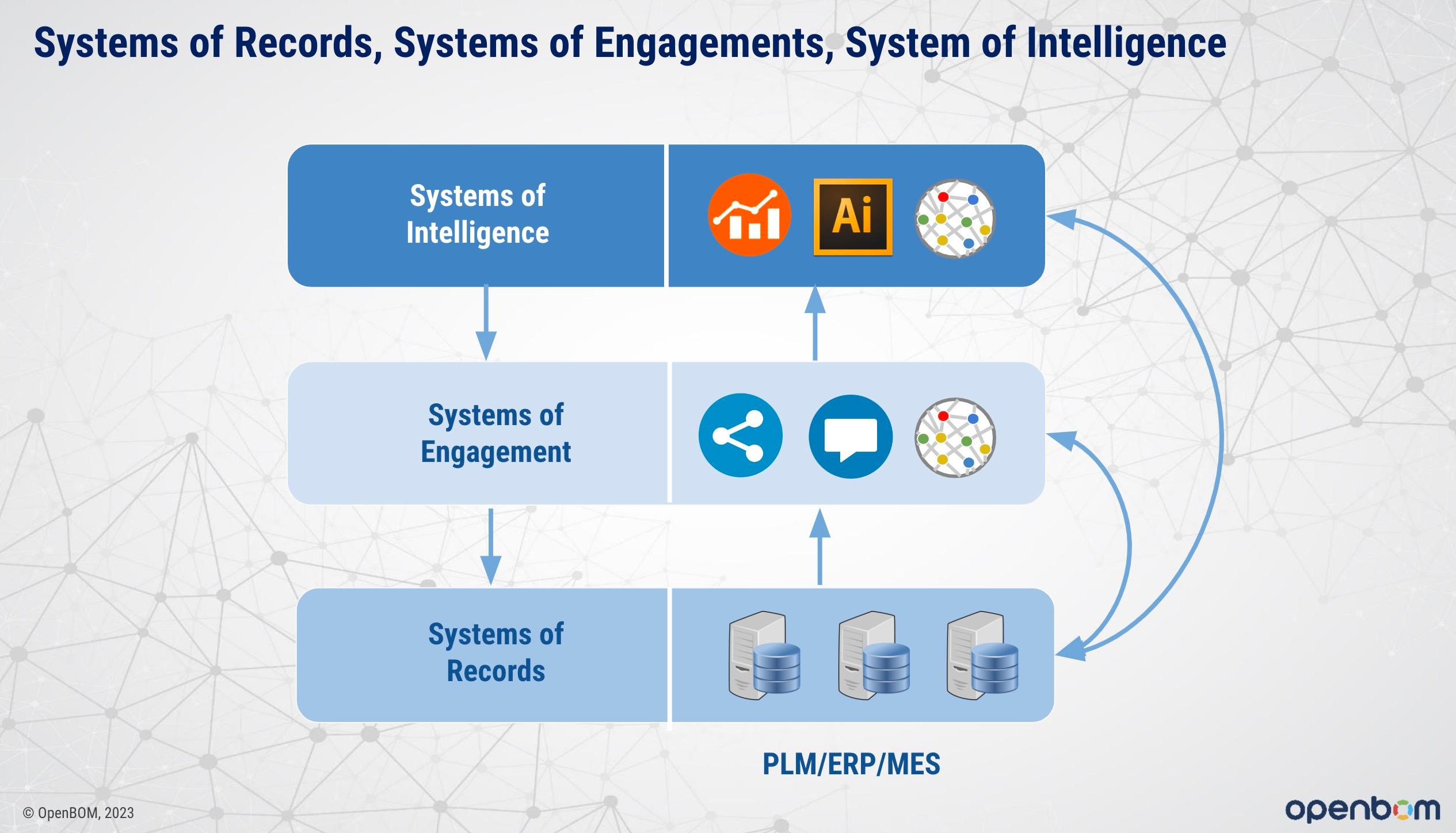

Data Usage Beyond Systems of Record (SOR): The trend of using data outside traditional systems of record is gaining traction to support systems of engagement. This approach enhances the ability to interact with data dynamically and in real-time.

Cross-Company Coordination and Communication: The need for accurate data extends beyond individual companies, especially in scenarios involving maintenance, support, and contract manufacturing. Ensuring data accuracy across various systems of record becomes a critical challenge.

All these points highlight the growing need for companies supporting manufacturing businesses to focus on obtaining data in an accurate, clean, and connected form. This will enable them to provide better services and fuel future solutions.

Possible Trajectories for Master Data Development

For the last decades, the trajectory of Master Data related development was focusing on aggregating, cleaning, and creating a consistent set of data records that can be used across multiple people and organizations in a company. Here are some trajectories of the development related to master data.

- Development of Holistic Flexible Data Models: Creating flexible data models that can absorb, explore, and act on data is crucial. This includes leveraging graph models, Large Language Models (LLM), and various generative AI initiatives.

- AI-Driven Connectors for Data Integration: Developing AI-driven connectors capable of automatically retrieving data from different systems is essential. Imagine Google crawlers on enterprise steroids, seamlessly integrating diverse data sources.

- User-Friendly Services for Data Visualization: There is a need for universal, easy-to-use services with user experiences that can visualize integrated data sets. This includes analytics tools similar to PowerBI, graph exploration and navigation tools, dashboards, and collaborative review and editing tools.

New database technologies related to master data capturing, organization and use are evolving and intertwining with expansion of online services available for companies. The three level of systems – SOR (System or Records), SOE (System of Engagement), SOD (System of Decision) are evolving in parallel and expanding in the organizations.

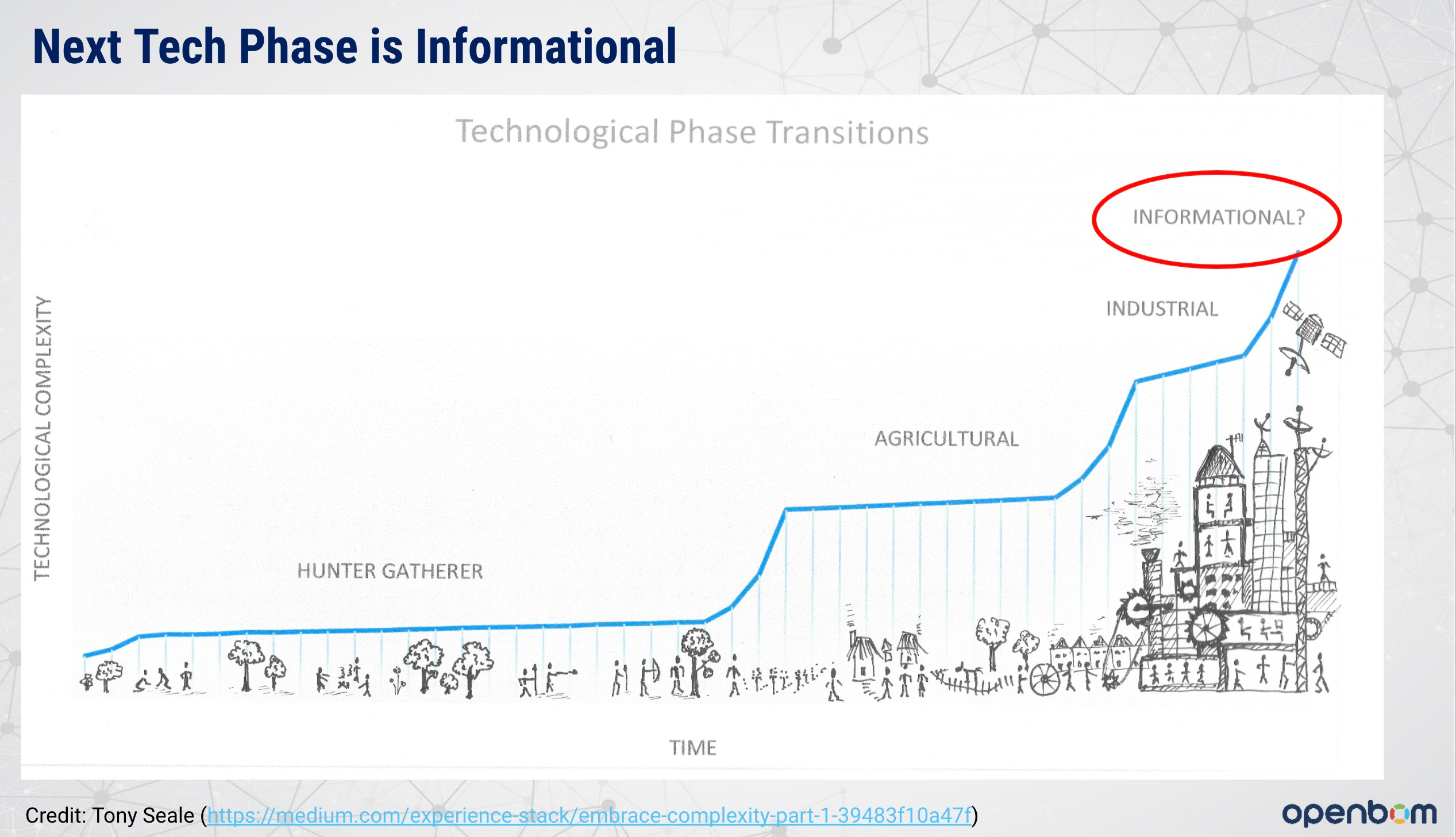

In my view, master data concept is becoming vertical in organizations to support the all three levels – SOR, SOE, SOD. Which will bring the most important point I wanted to make – it is all about data, how to collect it in a most reliable way, how to control it, how to make sense of data for decision making. Check my presentation from PI DX 2023 in Atlanta last year to learn how product knowledge graphs can become a foundation for master data in manufacturing organizations. The next tech phase is informational, therefore access to the data beyond applications will be more and more important.

What Is My Conclusion?

Product lifecycle management and product data management are transforming. The previous focus was on management of CAD documents and engineering release process. These days, companies are looking how to expand their activities and make PLM solutions and PLM software to focus on a wider scope of data to support a broad product development process. The ability to collect information and organize it in the way it can be used will be more and more important. Multiple systems of engagements (or collaboration) will be the next wave of systems that will overlay existing enterprise PLM (SOR) and offer services that will help companies to streamline processes, but at the same time will capture the data that is currently “lost in transitions” (Excel, Power points, Emails, etc.). These systems will be capable to provide a better “Master Data” control beyond old storages and monolithic platforms. Existing “mindshare” PLM vendors will be looking how to tap into this space and grab a portion of master data.

So, the battle for master data supremacy has began. Everyone understands that the future belongs to companies that can handle complex enterprise manufacturing data sets across multiple business systems and access data for business processes more efficiently. Mastering data management will be key to gaining a competitive edge in the ever-evolving landscape of enterprise software.

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital-thread platform with cloud-native PDM & PLM capabilities to manage product data lifecycle and connect manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.

Pingback: Beyond PLM (Product Lifecycle Management) Blog Breaking Free from Monolithic PLM: Building an Agile Strategy with Focused Services - Beyond PLM (Product Lifecycle Management) Blog()