In the realm of engineering and manufacturing, making products faster, better, and with optimal cost is one of the biggest challenges. Industrial companies are experiencing significant pressure and attempting to bring new products that can help manufacturers to overcome their biggest challenges such as working with not accurate data, speeding up new product development processes, and mitigating supply chain and regulatory risks.

The problems I mentioned above are big, painful, and require immediate attention. Unfortunately, as stated by many researchers and analysts in the PLM space, in the current state of PLM, companies are still using PLM for the implementation of basic functions such as design data management, change control, and release management. Very few did something beyond that and therefore, it is a very interesting aspect of future PLM system development.

For a long time machine learning and artificial intelligence was a topic of research that was not widely accessible to the general public. An average consumer recognized that there is probably something in the way large tech brands improve natural language processing, and image recognition and mimic some elements of human intelligence. But these features and functions were not positioned to substantially help every single user in their activity and to empower the human brain. Until ChatGPT demonstrated it with a Generative AI system.

This year will clearly become a year of AI. the time when Generative AI and other AI tools will get a substantial boost. The popularity of OpenAI’s ChatGPT combined with Microsoft’s investment into OpenAI created this 2023 AI moment. Companies are looking at how to leverage AI and bring AI-driven features to their products. It continues to bring more and more questions about what is the future of AI in enterprise software and how software companies can use AI and related technologies to their competitive advantage.

From my perspective, I’m interested in how AI can be used in product lifecycle management, product data management, manufacturing planning, and supply chain management as these are the main elements of any product’s lifecycle and core phases of any product development process. How AI can improve process management for any industrial company and improve the capabilities of PLM solutions for engineering and production processes.

The Era of Copilots?

Unless you live under a rock for the last few years, you have most probably heard about the so-called copilot. The term was taken from aviation, but in my view, it fits very well, the approach artificial intelligence and machine learning are taking to deliver AI features to mass users. Instead of pushing AI as a replacement for the human brain and intelligence, copilot features are introduced as a “helper” that can assist users in their everyday tasks – writing an article, preparing a presentation, crafting a marketing campaign, or creating documents. Behind the scene, it will use the power of machine learning, natural language processing, deep learning, neural networks, and capturing and processing of unstructured data.

Leading tech brands are looking now at how to embed generative AI in their products. I was skimming news and articles over the weekend related to the topic. Here are a few you can find interesting showing what Microsoft and Google do.

Microsoft unveils AI-backed Copilot for Teams, Word, and more

Google embeds generative AI features in cloud and Workspace

Dynamics 365 ERP adds Copilot AI functionality

Build 2023: Microsoft wants developers to build IT with AI

Google teases generative AI expansion within its own cloud

A few notable examples of Copilot AI tools using Generative AI – GitHUb Co-pilot from Microsoft and PathWay Language Model (PaLM) from Google, which largely overlaps with the GitHub co-pilot model. According to Google, the features similar to the capabilities of ChatGPT and Github Copilot including code generation in multiple languages:

Code generation. PaLM 2 generates computer programming code in 80 different languages, including Java, JavaScript, and Python. Code analysis. The model can look at a block of code and identify potential bugs or coding errors.

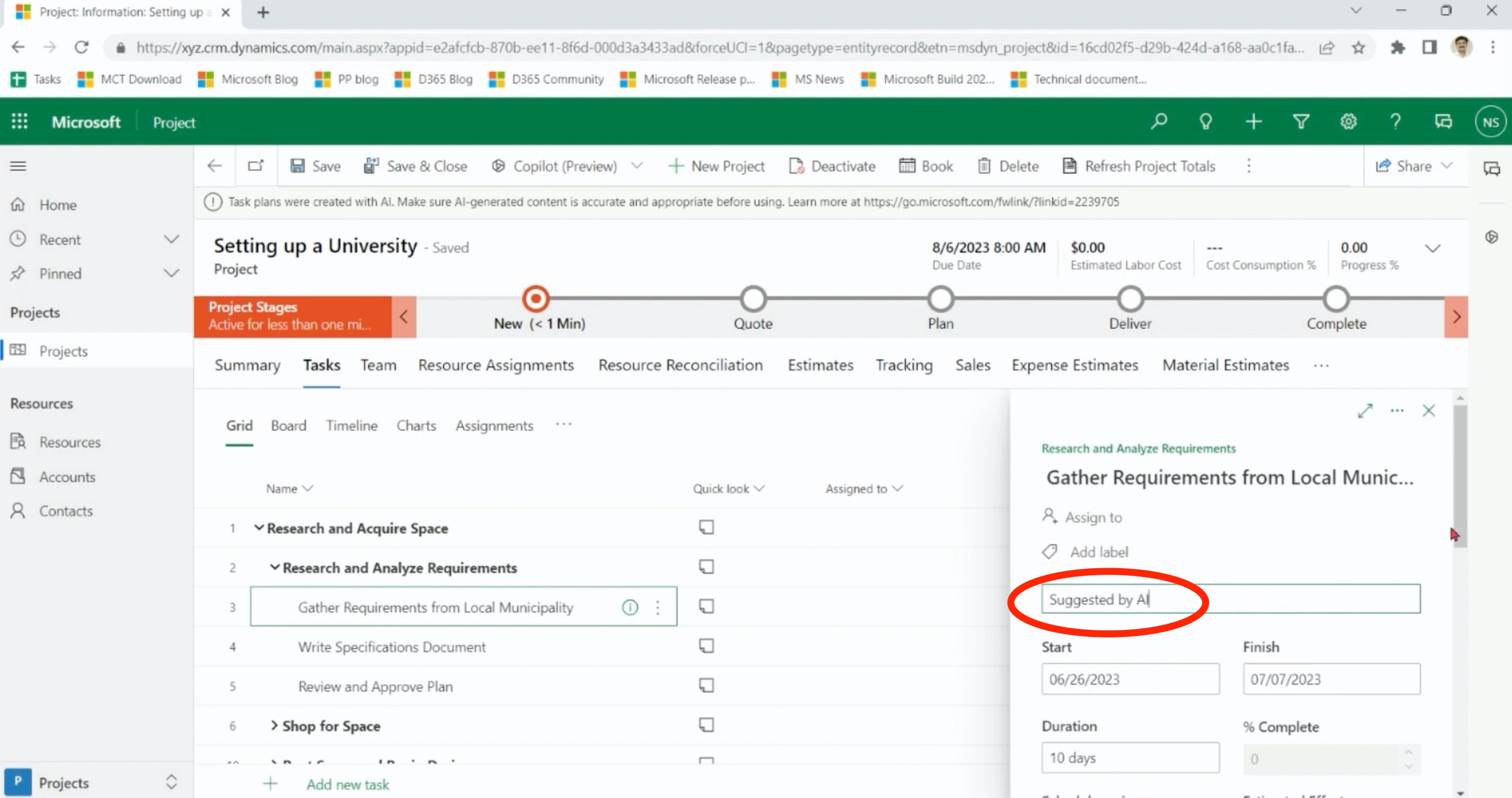

Dynamics 365 copilot is interesting. Check more here. The most interesting thing that I found is the ability of the Dynamics 365 Co-pilot to create project tasks based on the project context and additional information.

Are we going to see Copilots in PLM software?

A very interesting question about the usage of Generative API and co-pilots in PLM software. In my view, the question of how to use generative AI and co-pilot in PLM software is a topic of research by many companies these days. What if similarly to generative a suggestion for work-breakdown-structure (WBS), a system will be able to generate a product structure (aka BOM copilot)? I shared some of my thoughts earlier in my blog.

Ai-driven disruption in PLM: key takeaways from MIT imagination in action event

PLM trajectory from CAD files to product data, knowledge graphs, and AI/GPT

There are three fundamental questions that in my view, need to be resolved before technologies such as GPT will become useful in PLM scenarios:

- Contextualization of GPT models based on customer data

- Data security and IP protection

- Business models to make co-pilots with relevant data available for industrial companies

The PLM industry is just starting the GAI journey with much research underway. Here are a few interesting links and articles – SAP Co-pilot, Microsoft 365 Co-pilot, Oracle Linux Performance Co-pilot, Salesforce CodGen Co-pilot, OpenBOM BOM Copilot research (please note- I’m OpenBOM CEO and cofounder).

What is my conclusion?

A lot of work is happening now in the AI space. In my view, the era of PLM co-pilot is coming. I’m not sure about the names, but what is clear is that all companies are looking at how to harness the power of data to streamline operations, to speed up processes and product development. And these are the most important things for industrial companies. Every manufacturing company in the world is looking at how to make money, save money and reduce risks. The question is how to get help. Copilots can leverage previously accumulated data to help companies with all these tasks. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital thread platform including PDM/PLM and ERP capabilities that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.

Best, Oleg