In the world of engineering and manufacturing, data integration is paramount. As industries evolve towards more interconnected systems, choosing the right integration framework is crucial for efficiency, interoperability, and scalability. integration of enterprise resource planning systems (ERP), supply chain management, product lifecycle management and business processes in a modern enterprise can be complex task.

How to choose the right technologies to integrate existing PLM and ERP systems? How to build business functions and integrated management systems to streamline product lifecycle management and supply chain. This is a place where digital thread begins. Cloud based systems can improve application integration and make them simpler. But choosing the right technology in a modern enterprise environment when a company run an existing PLM and specific ERP system, can be a complex task. Similar to that brining a modern PLM tools with existing ERP system and setting up mature desktop CAD system or modern cloud CAD integrated with existing ERP systems can be a challenge too.

Earlier this week, my attention was caught by discussion about OSLC (thanks Alex Bruskin and Jos Voskuil for brining this up). Check the following link for comments. If you never heard about OSLC, here this is your time to catch up during the weekend.

Check Alex’s article for a good summary of standards and initiatives by different CAD/PLM vendors and their customers – STEP, JT, 3DXML, PLMXML, as well as industry standard tech for integrations such as REST, GraphQL, etc. The discussion about standards reminded me all articles I wrote earlier discussing what technological options can be used for better integrations. Here are a few old links you can find interesting:

PLM and Evolution of Integrations

Is there a value in PLM data standards?

Future PLM integrations: data service standards via REST APIs

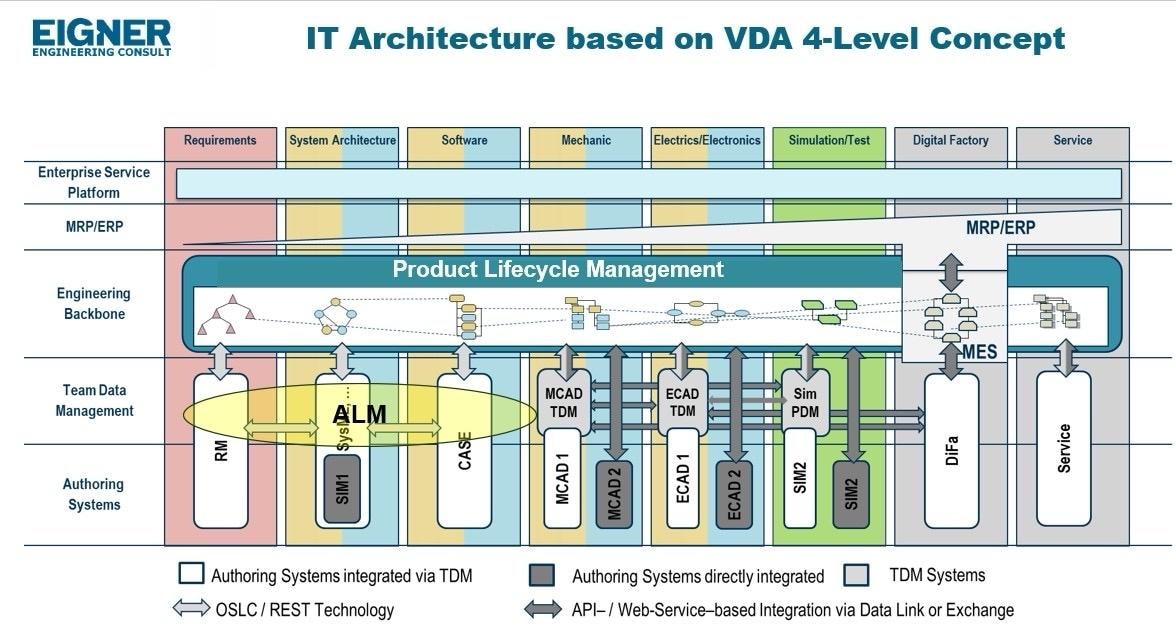

The last one was specifically interesting memory recollection when I’ve seen the following picture from Martin Eigner presentation showing options to bring data from TDM layer up to engineering backbone using either OSLC and REST technology.

If you never heard what is REST API, you can check this website or this article from Red Hat. There are many others. Check this IBM video- you can find it helpful.

I think many companies are asking the question what is the right technological choice for their integration efforts. Should the rely on open standards and web service interfaces such as REST, GraphQL and different integration tools or, as an alternative to invest into technologies like OSLC and integration platform supporting them.

In this article I will try to give my perspective on strengths and weaknesses of each approach, aiming to determine which is better suited for different use cases in engineering and manufacturing integrations.

Understanding OSLC

OSLC is a set of standards created to simplify and unify the way software lifecycle tools communicate and integrate. Originating from the need to streamline collaboration across diverse tools, OSLC provides a standardized way for tools to interoperate, focusing on:

Interoperability: OSLC enables tools from different vendors to work together seamlessly, ensuring data flows smoothly across systems.

Standardization: It offers standardized data models and interaction patterns, reducing the complexity of integrations.

Traceability: OSLC supports linking data across lifecycle stages, maintaining traceability from requirements to delivery.

Understanding REST API

REST is a technology that uses standard HTTP methods (GET, POST, PUT, DELETE) for communication between systems. It has become a widely adopted paradigm due to its simplicity and flexibility. REST emphasizes:

Simplicity: RESTful APIs are simple to design and understand, making it easy for developers to implement integrations.

Scalability: REST’s stateless nature allows for high scalability, essential for large-scale manufacturing systems.

Flexibility: REST can handle a variety of data formats (JSON, XML, etc.), offering flexibility in data representation.

How to compare OSLC and REST?

I will try to compare different aspects of integration building between systems to compare what is the best approach to build integrated environment.

Interoperability

OSLC was built specifically for interoperability, OSLC excels in scenarios where diverse engineering tools need to work together. Its focus on standardization ensures consistent communication between tools, making it ideal for complex manufacturing environments where traceability and compliance are critical. At the same time REST APIs is highly flexible and can be used to create interoperable systems, it lacks the built-in standardization of OSLC. Developers must define their own data models and interaction patterns, which can lead to inconsistencies and increased development overhead.

Scalability

OSLC‘s design focuses on interoperability and traceability, but it can be less efficient in highly scalable environments due to the overhead of maintaining standardized interactions and data models. Opposite to that, REST’s stateless architecture makes it inherently scalable. It can efficiently handle high volumes of requests, making it suitable for large-scale manufacturing operations where performance is a key concern.

Ease of Implementation

Complexity of integrations can be a killer. Implementing OSLC can be more complex due to its strict adherence to standards. It requires a thorough understanding of OSLC specifications and often involves more upfront work to ensure compliance. At the same time, REST APIs are generally easier to implement and understand. Their simplicity allows for rapid development and deployment, which can be advantageous in fast-paced manufacturing environments.

Flexibility

Flexibility is a key in PLM and other applications of engineering and manufacturing. While OSLC’s standardization promotes consistency, it can also limit flexibility. Adapting OSLC to unique use cases may require significant customization, which can be cumbersome. On the opposite side, REST offers high flexibility, allowing developers to tailor APIs to specific needs. This adaptability is beneficial for integrating diverse systems and accommodating evolving requirements.

Semantic Data Layers and Graph Product Models

While speaking about integration technologies, it is important also to mention data modeling technologies. Because organizing data models is a key for successful integrations. Both OSLC and REST requires data models to integrate the data. Engineering and manufacturing disciplines are complex and demands sophisticated models to organize data. It is a place to think about wht can be an efficient data model for future PLM. Check my articles

Why do you need a graph model to embrace PLM complexity

3 Benefits of using graph-based digital thread product models for PLM-ERP integrations

How to include graphs and networks in PLM architectures

What Is My Conclusion?

Choosing between OSLC and REST depends on the specific needs of your engineering and manufacturing integrations.

The robust OSLC framework can ensure consistent communication and compliance. It is good for complex and regulated environments. When standardization is a your primary concern, this is probably a better choice. Keep in mind you will need to make your tool OSLC compliant, which is an additional cost and complexity levels.

When you need scalability, simplicity and flexibility, my recommendation is to choose REST. The use of REST API is widely supported by all SaaS applications and integrated frameworks. REST’s ease of implementation and performance advantages make it suitable for large-scale operations and rapid development scenarios.

Finally, REST vs OSLC are not mutually exclusive. You can use REST API implementations of OSLC and OSLC is using REST for some implementations. I’m curious to learn more from people with integration project experience of both. One size doesn’t fit all in PLM integrations. The best approach may involve leveraging both OSLC and REST, capitalizing on their respective strengths to create a comprehensive and efficient integration strategy for your engineering and manufacturing systems.

Just my thoughts…

Best, Oleg

Disclaimer: I’m the co-founder and CEO of OpenBOM, a digital-thread platform providing cloud-native PDM, PLM, and ERP capabilities. With extensive experience in federated CAD-PDM and PLM architecture, I’m advocates for agile, open product models and cloud technologies in manufacturing. My opinion can be unintentionally biased.