In today’s world, more and more companies need to collaborate globally. In the supply chain, this is a result of companies wanting to optimize their operations and having more suppliers involved in all processes of their activities. There are many solutions that companies are using for the global supply chain. With the current development of online tools, internet, and services, most of these tools have established online spaces where you can share and exchange information and transmit messages.

But something makes me feel unhappy about these tools and spaces. What I dislike is that most of them create their own eco-system. I think there will be a significant improvement if we are able to connect these solutions to organizational processes. But this is not always possible because companies today do not share their processes. In most of the cases, they use different tools to implement business process management in their organization.

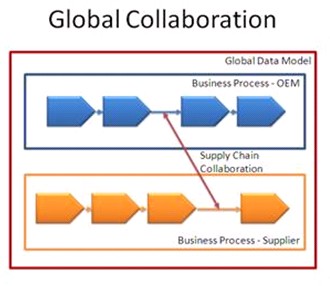

How can you make this collaboration possible? In my opinion, development of process interoperability can provide a new dimension in how company processes work together. The ultimate requirement is to keep processes separate, but, at the same time, allow them to work together. The main problem of such integration, as I mentioned above, is that because business processes are separate, data-base schemas are different. Each company process uses its own data schema to represent information which is tightly bound to a specific process implementation.

Today, I can observe two major ways process integration occurs: (1) mapping based approach; (2) query based approach.

For the mapping based approach, the integration creates a map between two local schemas. By doing this, a new “federated schema” is created. In some cases, companies are trying to use one of the schemas as a federated one. This is not always possible as sub-sets of schemas are used. But whatever the final schema is, this process is complicated and requires multiple mapping operations to happen. This way is also expensive, in my view, for long term support and changes. You can see some examples of this approach here: http://www.research.ibm.com/journal/rd/485/zhu.html

Another approach is query based. In this approach, a special interoperable query system needs to be developed. This “query” is able to establish a connection with both (or multiple systems) and extract/load information. With the latest development of SOA and Web Services, this way has become very popular. You can see example of this approach here: http://www.oracle.com/applications/pip-for-oracle-product-hub-data-sheet.pdf

I’m thinking about different way – integrated ontology development. This ontology would place a super-set on top of both business process models. Ontology, in simple words, is a data model. So, we need technology and/or a tool that wold allow us to develop an intermediate data model. There are such technologies in today’s world developed as part of Semantic Web W3C initiative – technology based on RDF (Resource Description framework) and OWL (Web Ontology Language).

[youtube=http://www.youtube.com/watch?v=mVFY52CH6Bc]

These technologies have been developed for the past 7-10 years and, in my view, have become more and more popular. They allow you to establish a global model for content and message transfer, thereby simplifying communication. The main advantage of this collaboration is that a new level of data models will be created. These data models, represented by RDF/OWL, will allow companies to establish a connected data environment that can be used by multiple systems.

And, to make some fun, take a look on this video. Even if content is not related to supply chain yet, the core idea of integration is the same.

[youtube=http://www.youtube.com/watch?v=hAAwKxeoCrk]