The PLM industry is finally moving a full speed ahead toward the cloud. Remember the cloud debates 10 years ago? Here are some old posts to refresh your memories – PLM and cloud trap, Top 3 PLM cloud killers. My favorite old article is the one I wrote back in 2016 after the Siemens PLM analysis conference in Boston. Check this out – Chasing the right PLM cloud. My favorite picture is from Jim Brown’s Tech-Clarity research – every cloud option came with tradeoffs.

A fast move to 2022 and we can see how PLM vendors are following the cloud path marketing their platform in a variety of forms – cloud platforms, true SaaS, cloud-native, etc. Earlier this week, my attention was caught by CIMdata commentary CONTACT Cloud – Bringing CONTACT Elements to the Cloud (Commentary). Check this out. I found the most interesting the following passage and the picture.

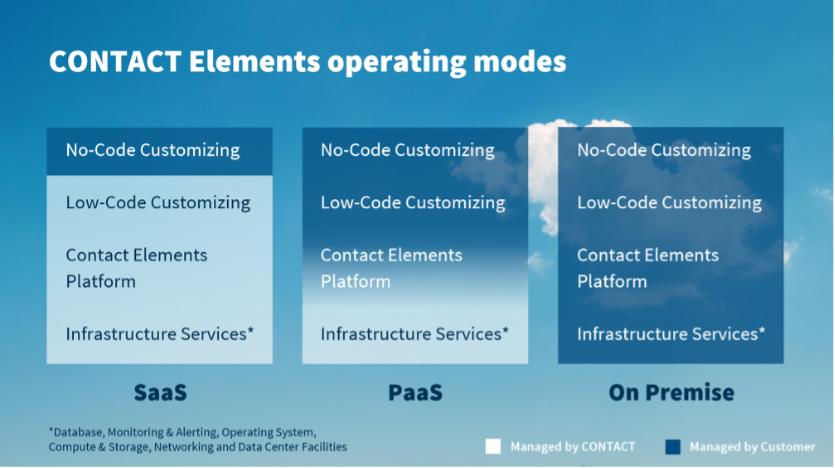

CONTACT Cloud, their cloud offering, builds on the strengths and experience with CONTACT Elements as shown in Figure 1. CONTACT Cloud is a preconfigured, ready to use PLM solution based on the platform. It is offered today on Amazon Web Services (AWS), the leading cloud hyperscaler. But CONTACT is exploring support for other hyperscalers like Microsoft Azure, Google, and other regional cloud providers. Their cloud offering uses standard cloud deployment tools and services, including Docker, Kubernetes, and Database Services for Oracle DB. CONTACT takes care of provisioning, monitoring, and securing the cloud instances and manages the relationship with the hyperscaler. This is important because an ISV like CONTACT Software will have more buying power than an individual company. CONTACT Cloud customers have no business or legal relationship with their hyperscaler. It is all handled by CONTACT. Their Instances are updated automatically or on a schedule defined by customers. This greatly reduces the IT management burden on industrial companies, ceding resources that can support more strategic investments.

The commentary made me think about the evolution of existing PLM systems and their ability to transform between multiple cloud options.

What Do Customers Want From Cloud PLM?

PLM infrastructure is complex and for the last 15-20 years proven to be hard to maintain, upgrade and use without significant support from PLM vendors and service providers. Large enterprise companies were able to afford it, while smaller manufacturing companies found themselves in a PLM release trap. These companies invested millions in PLM implementations but were not able to keep up with the new releases, expensive upgrades, and inflexible legacy PLM systems. Therefore, industrial companies are looking at how to escape from the PLM legacy.

For the last ten years, cloud services, technology, and infrastructure as a service offering became more reliable, secure, and acceptable for many organizations including manufacturing companies. Most of them are open to running their enterprise systems in the cloud and many of them are moving their IT infrastructure to hyperscalers as CIMdata called it in the commentary.

The opportunity PLM vendors found is to merge the interests of their customers to get rid of PLM complexity by offloading their PLM stacks to become hosted using AWS, Azure, or GCP. It sounds like an interesting opportunity for many organizations basically apply the “hosting” paradigm and take their existing mature platforms and deploy them using modern digital technology, and DevOps tools.

On-Prem, SaaS, and PaaS in a single package?

You can have our PLM on any platform and in any package – SaaS, PaaS, or On-prem. This message is really powerful and PLM vendors play it in the customer’s ears loud and clear. Don’t worry – you can have it in any way you want and even move back and forth as you wish. Here is the passage from CIMdata commentary about it.

…Customers in need of customization beyond low code have the option to switch between cloud and on-premise implementations. A company can start with the cloud version and decide to change to on-premise. The reverse is also possible, making it easier for customers to meet the changing IT deployment needs of their organization. CONTACT supports customers by either importing their data into the cloud instance, or by exporting it from the cloud to an on-premise instance.

However, this message also explains the architecture of PLM products that support this multi-cloud architecture approach. From a technical perspective, these systems are identical and the only difference between them is the deployment environment. The limitation of customization for the SaaS option reminded me of OOTB (out of the box) PLM circa the 2000s when applications provided preconfigured functions but not provided any ways to change them.

I found the triple platform of On-Prem/PaaS/SaaS becoming popular over the last few years. You can see the same pattern is repeated by multiple vendors – Siemens (TeamcenterX), PTC (Windchill+), and Aras (Enterprise SaaS).

The question I expect customers to ask is what is the right approach to fulfill digital transformation needs, bring the right tools and optimize business processes while reducing the cost and burden of maintaining expensive legacy PLM products. The answer is not as simple as you can think initially. Hyperscalers such as AWS, Azure, or GCP are the silver bullet PLM vendors are using to prolong the lives of their existing platforms and deliver proven applications to customers. What customers need to do is to evaluate these applications from the perspective of their modern needs for digital transformation:

- Openness and integration

- Data sharing capabilities

- Intelligence and data usage

Let me share my thoughts about digital transformation demands and what can and cannot be done using universal PLM platforms.

Digital Transformation and Web Services

Cloud computing services are leading the way in digital transformation coming to improve the way companies streamline business processes. Back in the time when the existing PLM paradigm was born, the purpose of PLM was to manage data, organize control, and access information. By itself, it is an important goal. However, is it really enough for modern manufacturing transformation, reducing supply chain management risks and integration with the rest of the digital technologies available online today?

Manufacturing is fast turning into a network of companies cooperating and working together. Manufacturing businesses are switching from selling products to selling services and looking at how to build on-demand manufacturing platforms capable to build products based on customer demand and optimizing production and supply chain.

Legacy PLM platforms were mostly focused on the efficiency and ability to streamline processes. It was the goal, but now it is changing. Companies are looking at how to focus on effectiveness and decision making moving away from simply optimizing existing processes. How to extend system support from process efficiency to effective decision-making is the real question. Here is the passage from my article in the OpenBOM blog – System of Intelligence, Decision Support, and Manufacturing Effectiveness.

For years, PLM systems were implemented to make things work efficiently. Making file releases, storing data about the product, and simplification of revision control, support the change management process, PLM vendors were focused with speed and productivity while organizing the most efficient process. Cloud PLM (or SaaS) didn’t do much difference in PLM systems. Most vendors understood the cloud simply as a way to deliver the same PLM system, faster, cheaper, and with less effort. Upgrade of PLM systems to the next revision, which for years was the biggest PLM challenge is actually also an element of efficiency.

What is heavily overlooked are tools that can help us to make the right decision or, in other words, to decide what to do first. Such tools are not focusing on how to do revision sign-off or ECO approval faster, but first to decide that change is needed and what is the right change. A decision to replace a supplier from a bad supplier to a good supplier, selecting a specific vendor or component, and instant calculation of cost based on the design decision, can turn things upside down.

The paradigm change for PLM systems can be a switch of the focus from data management and process streamlining to artificial intelligence, data models, machine learning, and specific database queries applied for the decision support system to make engineering and company activities focused on what is right to do.

Legacy PLM systems are not capable to connect into a live network of services interoperating together to deliver the experience and data that are needed by modern manufacturing companies and businesses. Connecting to online data, optimizing the supply chain, and managing data of customers, suppliers, and partners without importing all information into a single SQL database.

In my article PLM 2030 and point of no return for fax machines, I shared my perspective on the future of connected PLM systems and how modern architecture will play the role in building a new type of PLM platform.

What is my conclusion?

Digital transformation, expansion of cloud development tools, and development capabilities to deliver better business systems is the clear goal of IT in all manufacturing companies these days. Bringing existing PLM platforms to platforms like AWS, Azure and GCP seems to be a good step towards breaking the legacy release cycle, switching the maintenance burden to PLM vendors, and allowing hybrid cloud computing to enter the doors of manufacturing facilities. At the same time, brining legacy systems to the cloud will not change them and companies are risking the be stuck in supported and upgradeable cloud silos without the ability to connect their PLM platforms to online digital services. For the last 10 years, the PLM industry passed the barrier of cloud adoption allowing to bring existing platforms to be hosted using hyperscalers like AWS. The next decade will be about how to connect systems together to make them work in a connected and coordinated fashion. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital cloud-native PDM & PLM platform that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.