I’m continuing to digest my 3DXW23 experience and what I learned. Design, engineering, and manufacturing are undergoing a radical transformation. With digital native experience becoming a norm, CAD/PLM (product lifecycle management) software-enabled workflows and business processes are enabling businesses to keep up with escalating customer demands and adapt faster in shifting market climates. But what does this mean for SOLIDWORKS customers?

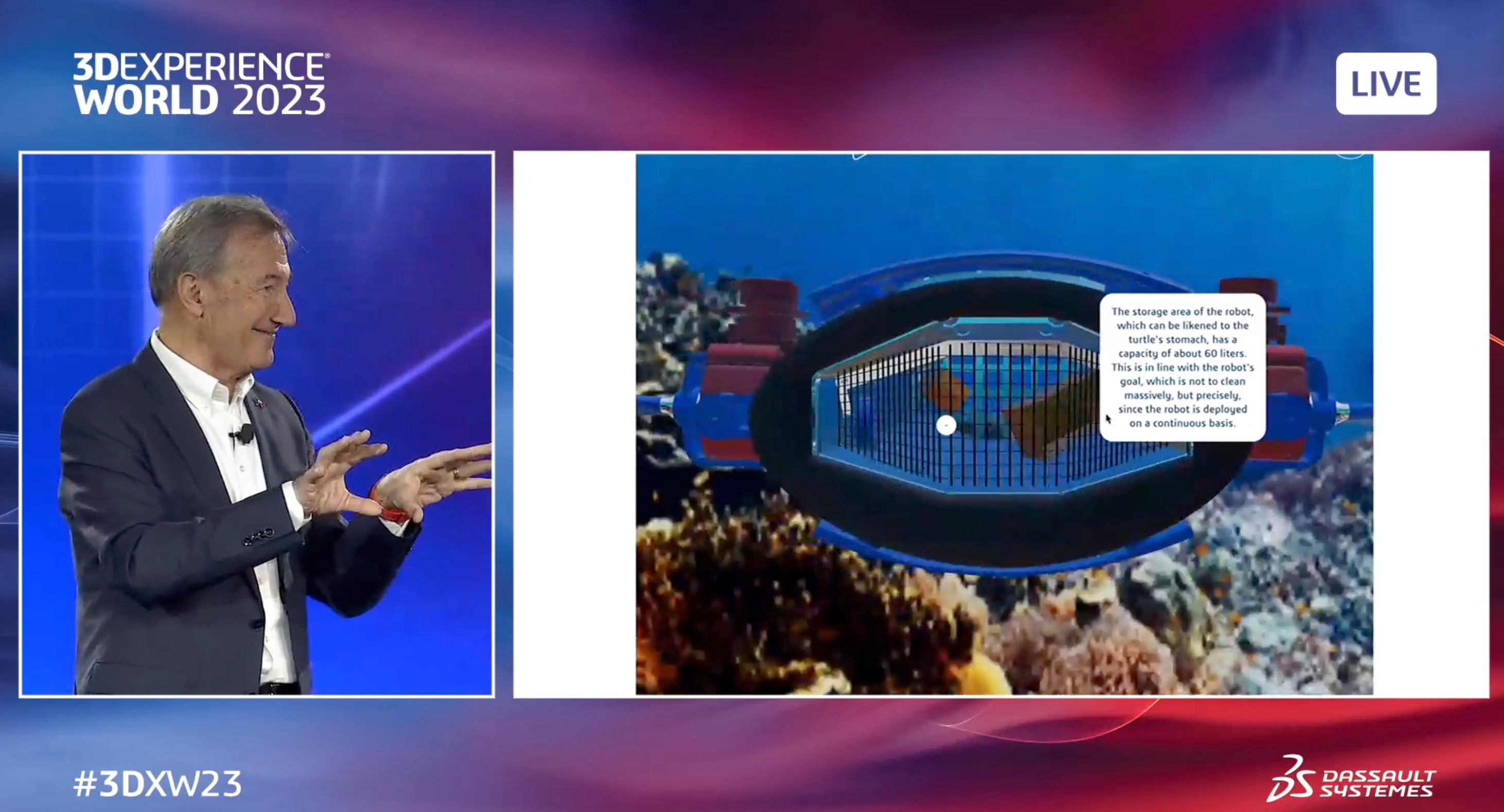

Last month, at 3DXW23 Bernard Charlès, Chairman and CEO of Dassault Systemes shared his views on the future of design and its impact on existing SOLIDWORKS mechanical engineering customers. Today, I want to share my insight and thoughts after the keynote presentation of DS Chairman and CEO Bernard Charlès.

Key Points of Bernard Charlès Presentations

In his visionary speech, he presented his perspective on some design trends and provided an intersection between bigger technological trends and 3DXEXPERIENCE development.

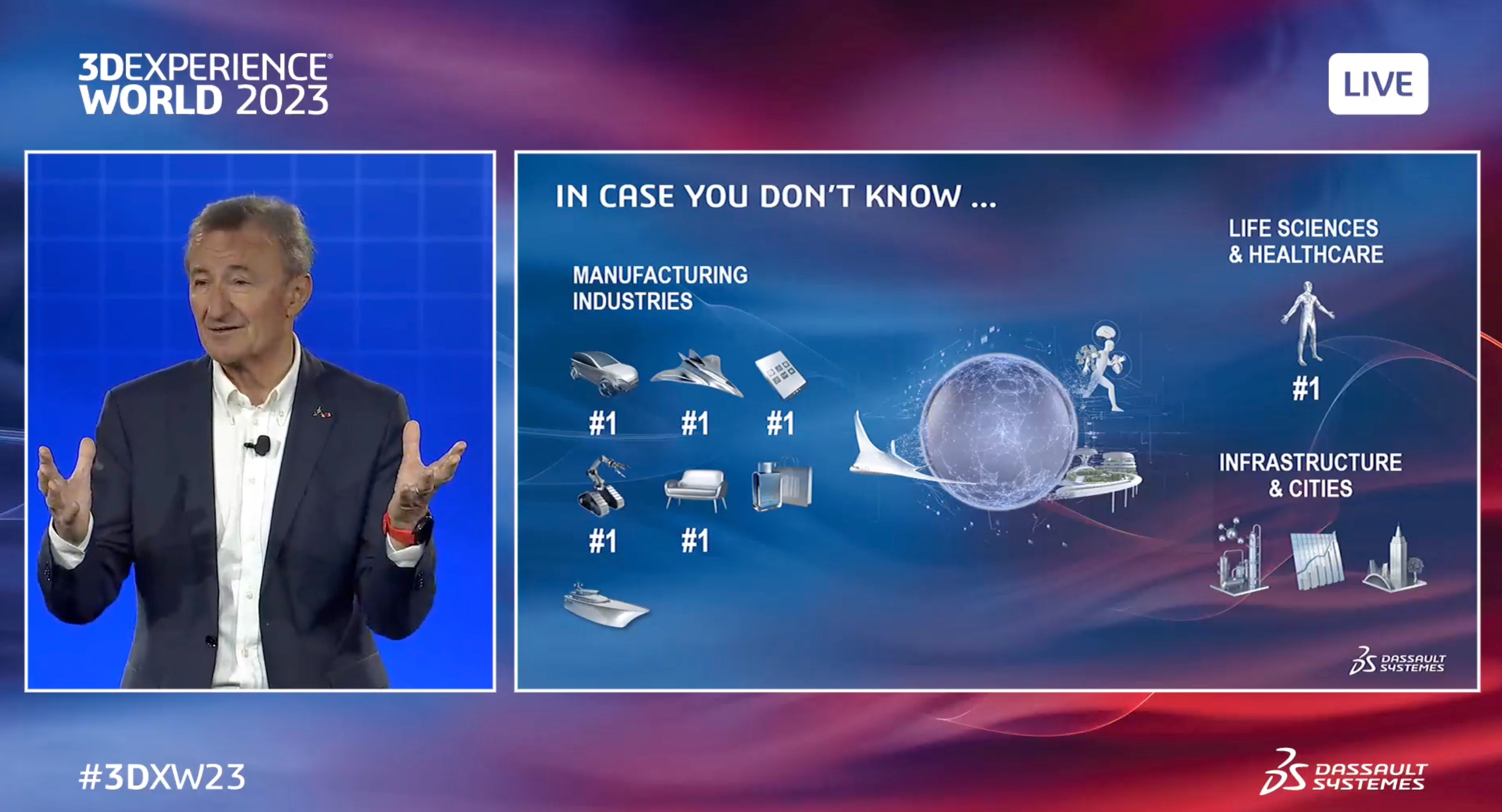

Global Manufacturing and Development Communities

DS is growing its eco-system of industries and Mr. Charles mentioned that DS is a player in all major industries from aerospace, automotive, industrial equipment, and many others.

As it was mentioned, the industrial machinery vertical is heavily presented by SOLIDWORKS customers in the 3DXW23 community.

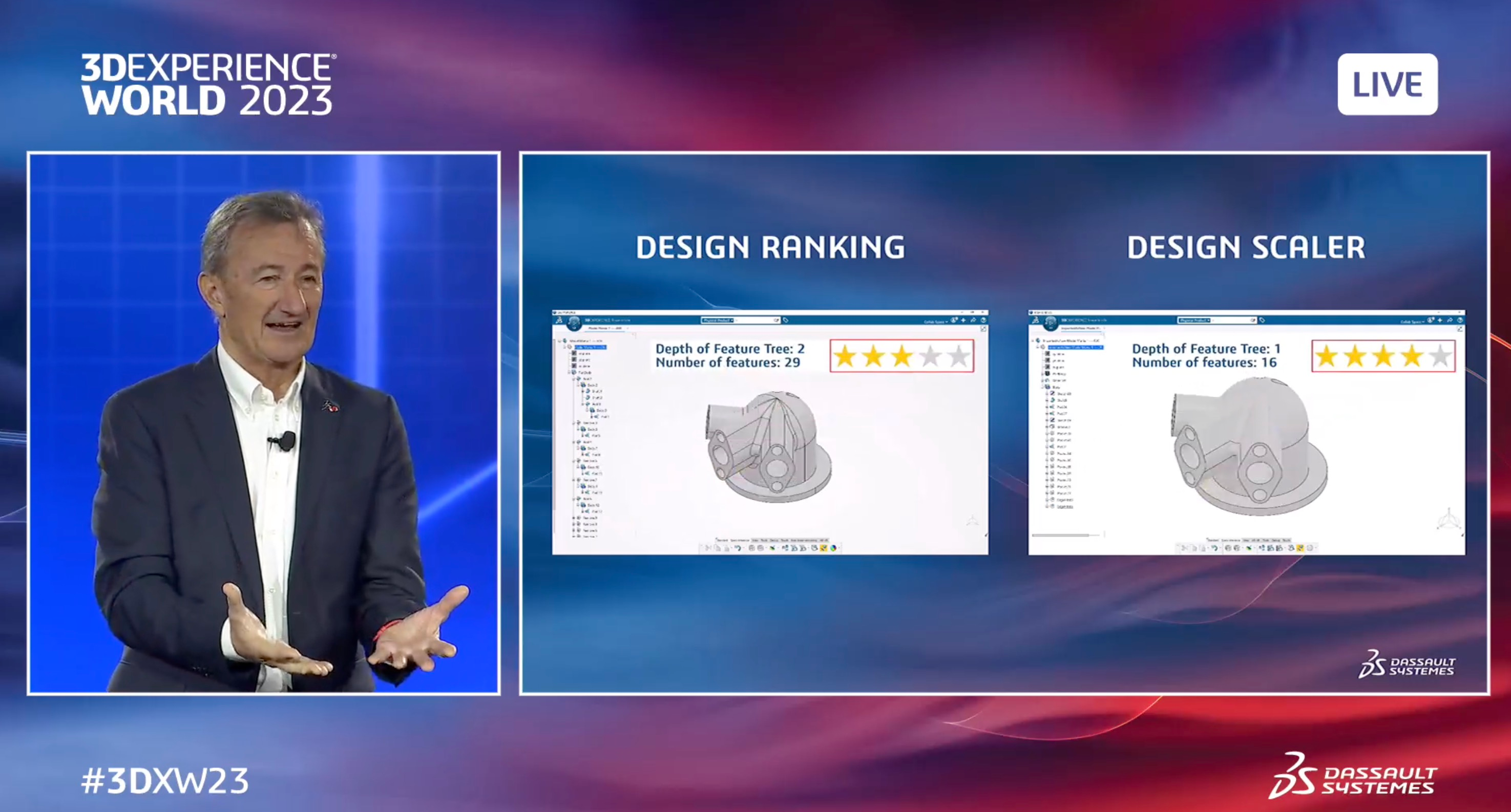

Design Quality and AI-enabled automation

Bernard Charlès mentioned ChatGPT and AI tech Dassault Systèmes is using in the 3DX Platform in the context of virtual twin experience. It was hard to understand if DS is actually using the ChatGPT platform or not. The example below is a design improvement process using (I guess) generative design capabilities. However, details were not mentioned.

The key message here was – we can automate design improvement.

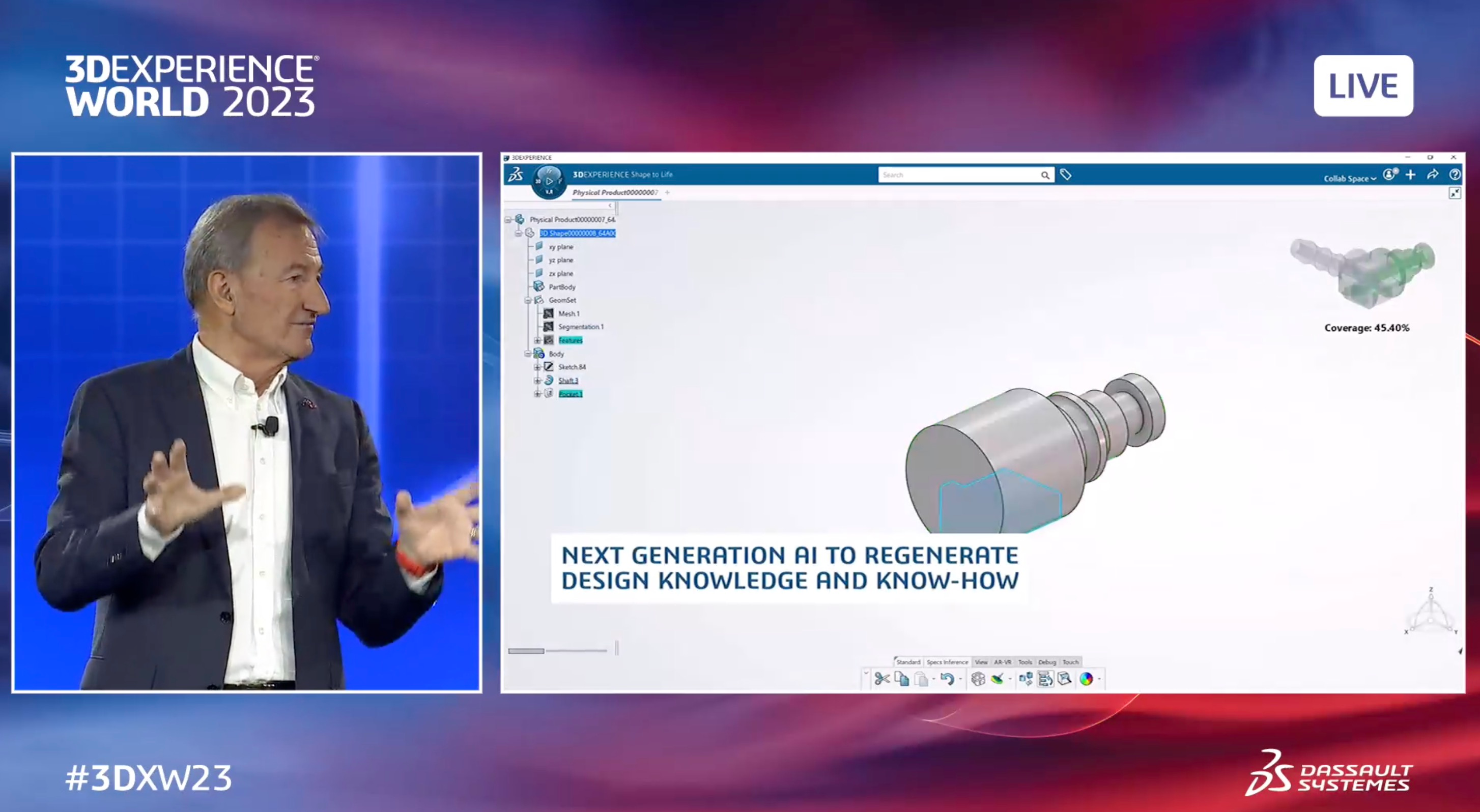

Regenerate The Real World Data

Capturing real-world data was the second main point. Supported by 3D scanners, the process of capturing existing parts and regenerating the design automatically looks fascinating. I can see many examples and use cases where similar experiences can be very beneficial (especially in the context of maintenance parts). Although, design speed is also an interesting aspect of this method.

Once, done with parts, the logical path is to move to manufacture and supply chain where there are many existing challenges with supply chains.

Material Planning and Supply Chain

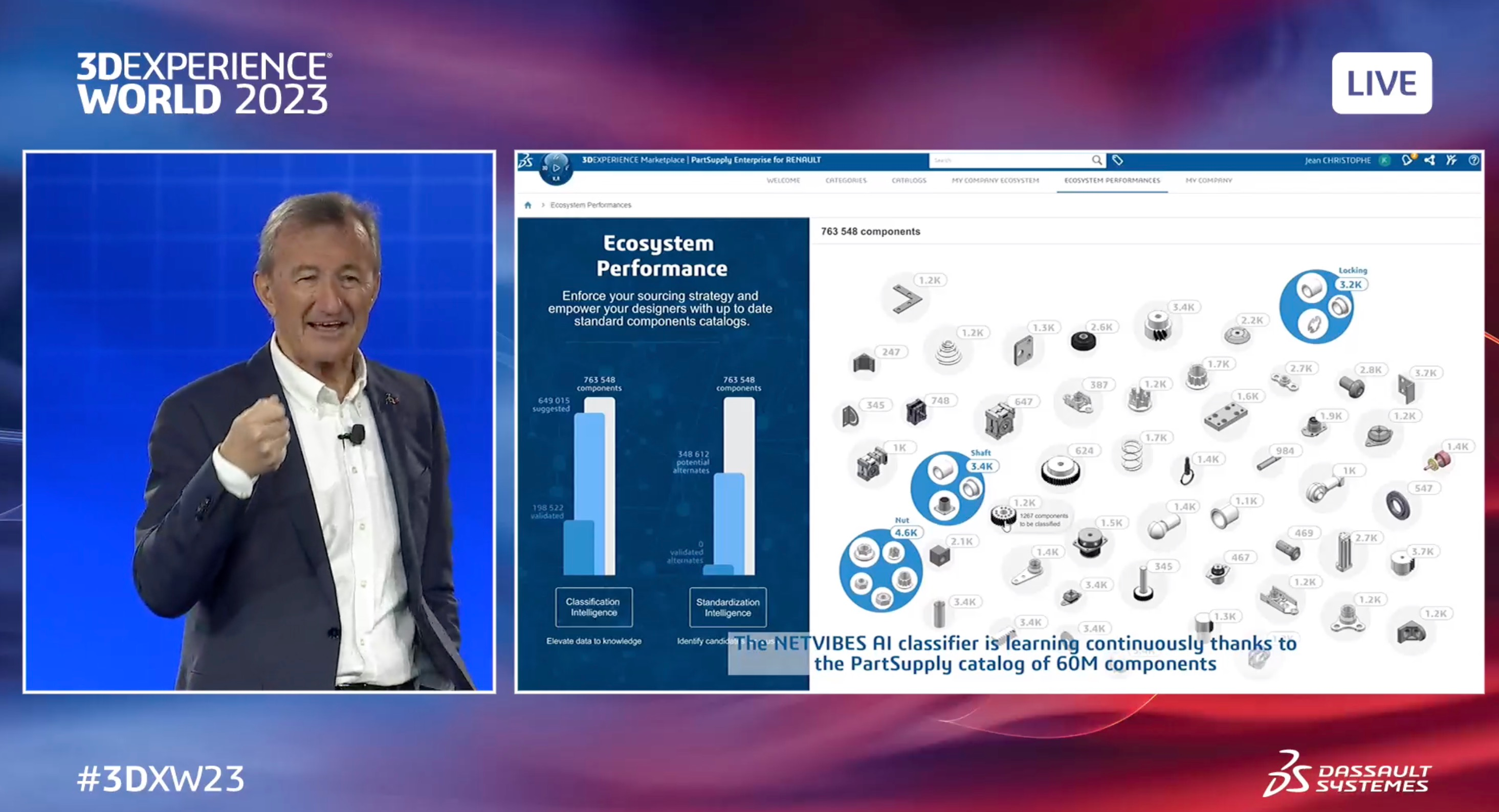

The example below demonstrate the new classification capabilities of the 3DX platform. It is not clear how they can be applied to existing SOLIDWORKS customer data. The demo was presenting the work, Dassault Systèmes made for one very large automotive company in Europe.

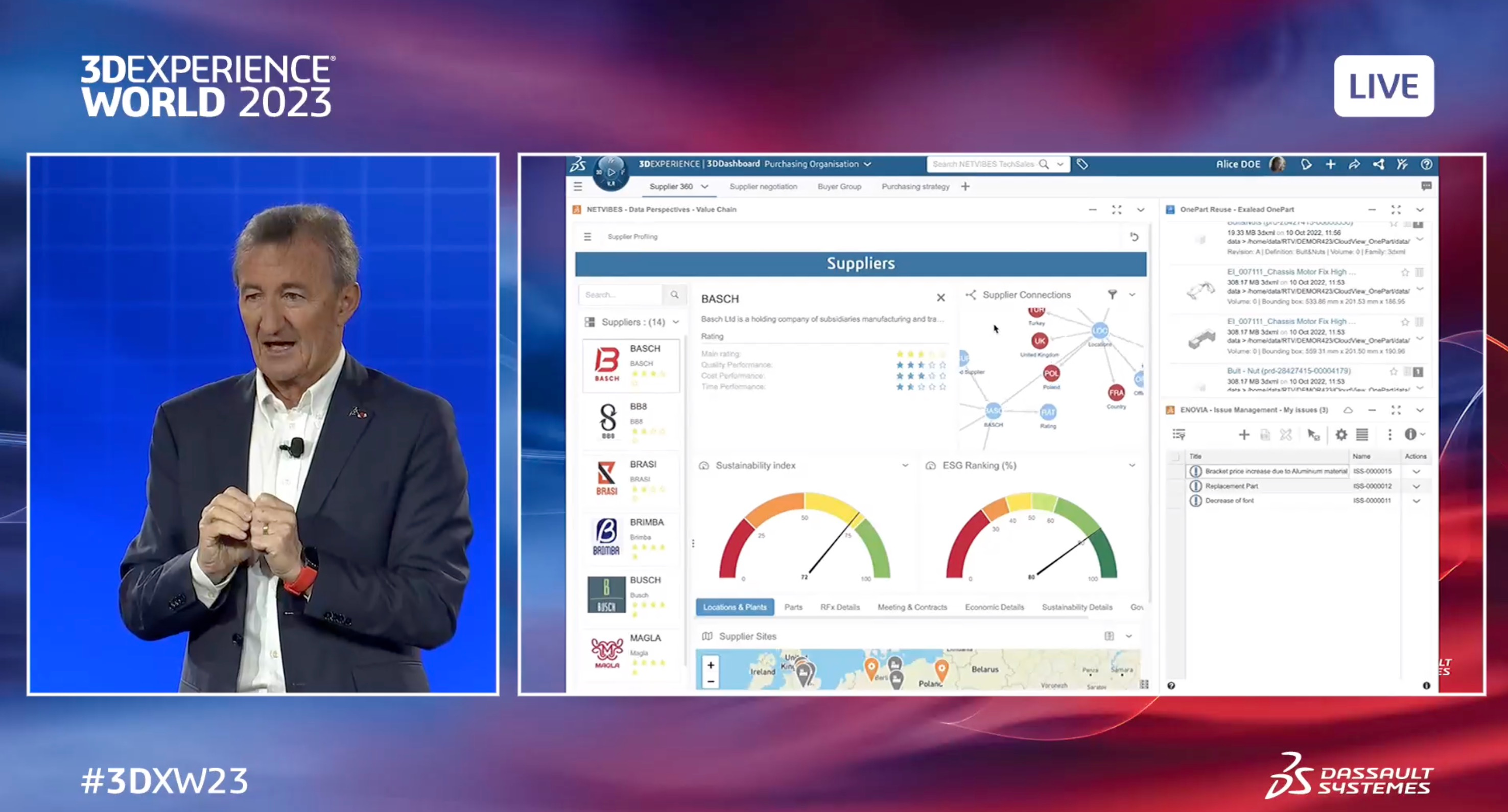

Selecting suppliers, making assessments of material, and purchasing options. It was a very visionary and interesting presentation,

My biggest interest in the selection of suppliers was related to the capabilities of the 3DX platform to connect to existing suppliers with all geographies and to support all existing options used by SOLIDWORKS customers in real life. Without that, all these new platform capabilities with be dead on arrival.

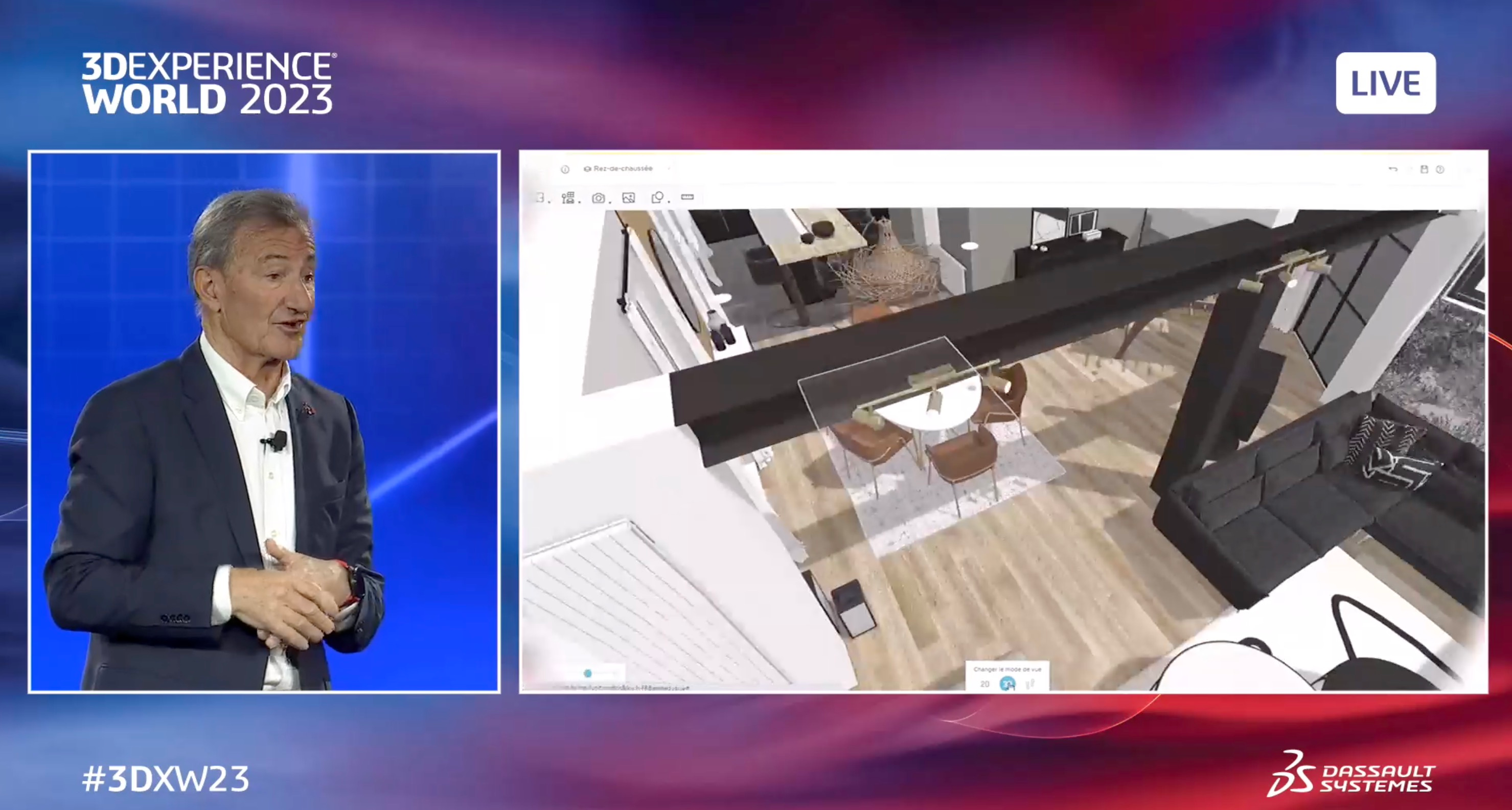

B2C Solutions – HomeByMe

Dassault Systèmes experimented outside of the box with IKEA building a new design platform – HomeByMe allowing consumers to design their homes and build them using IKEA catalogs.

The system is available online and I was able to make some very small tests. They are not scientific and I didn’t build a real design. However, I was more interested in the user experience.

What was very inspiring is that it doesn’t have heavy roots in existing CAD/PDM/PLM platforms. All existing PLM platforms have this complex experience inherited from years of enterprise solution development. You can see the same complexity in the 3DEXPERIENCE platform too. But HomeByMe doesn’t have it.

SOLIDWORKS Customer Experience and Major Paradigm Shift

3DXW23 is a new event, which the first time happened back in 2020 before the COVID pandemic hit the world. Although it is presented as a 3DEXPERIENCE event, the community of attendees is largely presented by SOLIDWORKS eco-systems and customers. Therefore, I can see some interesting projections of new 3DX experiences for SOLIDWORKS customers.

The traditional roots of SOLIDWORKS customers and all engineers involved in SOLIDWORKS design and eco-system are heavily influenced by existing SOLIDWORKS products that were first time born back in the middle of the 1990s on top of the Windows platform success. Until now, the majority of CAD design is done using the same paradigm – desktop CAD application heavily mixed with Folder/Files data management user experience (even the most successful existing SOLIDWORKS data management PDM product is mimicking Folders/Files with the database backend).

The introduction of 3DX cloud services to all SOLIDWORKS customers is a big paradigm shift in the way customers will operate and use their tools. Even the best change is hard. Such a fundamental change will be extremely hard for customers and will require a re-alignment of workflows and processes.

So far, DS was growing 3DEXPERIENCE with the large influence of major manufacturing brands. The example of a car manufacturer experimenting with the supply chain of components above is one of the examples. How similar experience will be applied to manufacturing and engineering companies using SOLIDWORKS is the question that I think was at the air of the conference as I was talking to attendees.

Design experience with products like HomeByMe is very interesting. Because it introduces an example of how a new experience (different from the 3DX Platform) is presented to customers. As far as I understand from Bernard Charlè’s presentation it has its roots in the same platform, but the experience is completely different.

Bernard Charlès was talking about life synthesis-based paradigms used to design new products with the example of a turtle robot.

It made me think about what paradigm the 3DX platform needs to use to help mechanical engineers using SOLIDWORKS to adopt new data management tools, improve collaboration and optimize the supply chain. I didn’t find the answer to this question at 3DXW23. But this is a topic for a separate blog article.

What is my Conclusion?

New tech and methods are here. The capability of technologies used in AI and the cloud are inspiring to bring new design tools and new experiences. But the main challenge is the change, in my view. DS is full power ahead to transform the community of SOLIDWORKS customers with new products connected to existing SOLIDWORKS desktop products. It includes cloud services that will be available to all SOLIDWORKS customers from July 1st, 2023, and also a bunch of new tech and system roles coming from 3DEXPERIENCE platforms. As much as I’m excited to see these technological innovations, the question of how to find new experiences to replace a super successful SOLIDWORKS Desktop/File/Folder paradigm with the cloud tools will be the key challenge for DS. New data management paradigms are hard. When SOLIDWORKS picked the Windows experience, it followed the platform trend and it was a super successful thing. These days we have many new paradigms coming from the web, mobile, connected, and metaverse experience. Will it help SOLIDWORKS customers to evolve into a new DS Platform reality? What will be a successful new experience for all engineers using SOLIDWORKS now and tomorrow? Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a global digital thread platform providing PDM, PLM, and ERP capabilities and new experience to manage product data and connect manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.