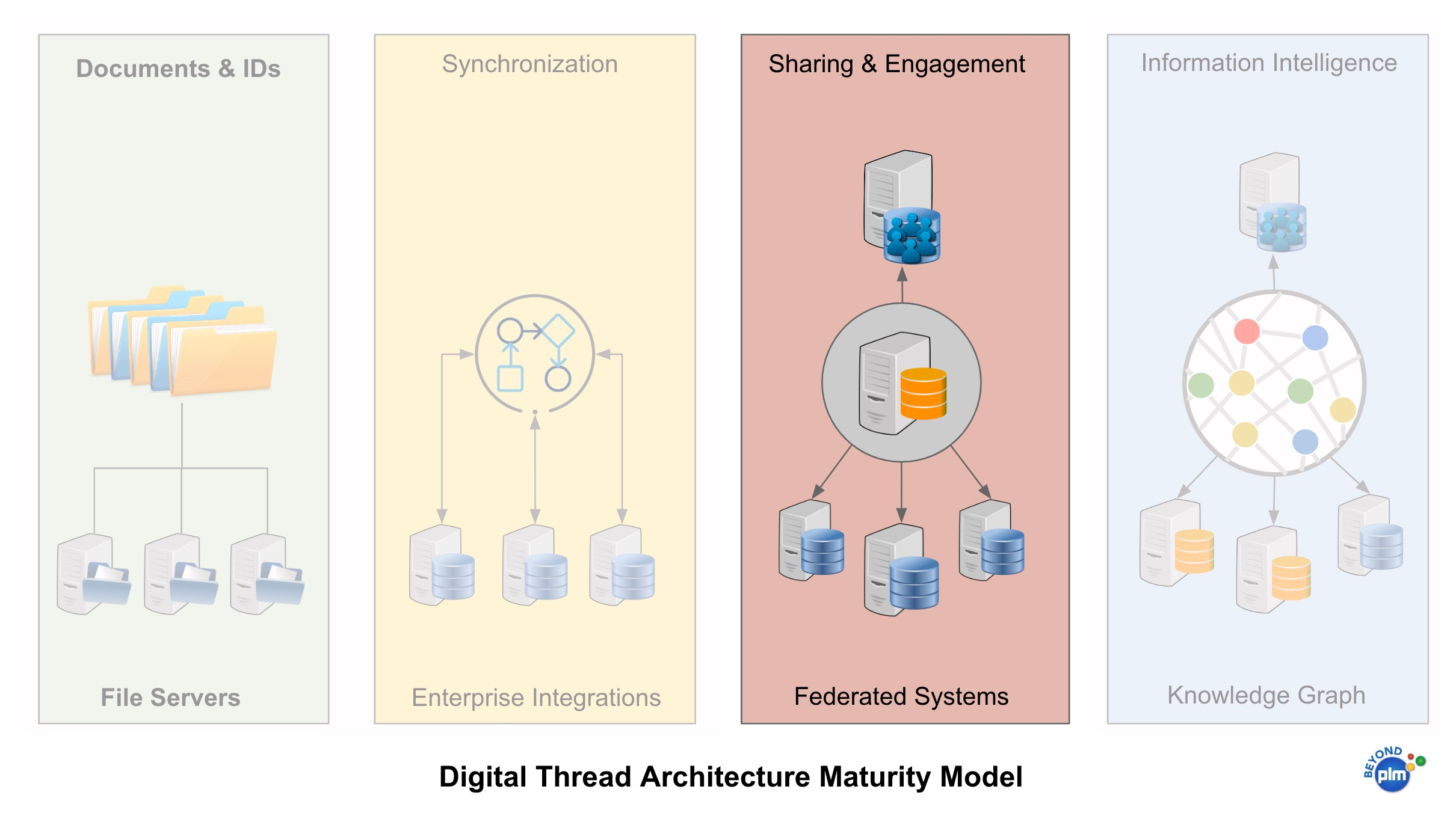

Manufacturing companies are looking into the digital thread of data across multiple stages of product lifecycle as the method to digitally transform manufacturing operations in many industries. In my earlier articles, I shared my thoughts about the evolution of digital thread and the way companies are implementing digital thread from a very rudimentary approach such as the intelligent part number and later in the process of building enterprise integrations. Check my previous articles

Digital Thread Evolution – Overview

Digital Thread Evolution – Folders, Files, and Part Numbers

Digital Thread Evolution – Enterprise Integrations

In my article today, I want to talk about data sharing and data federation.

From Syncing to Data Linking and Sharing

Enterprise integrations created mechanisms allowing to transfer of data from one application to another. In such a way you can transform BOMs, documents, and other pieces of information needed to be accessed in different systems. Manufacturing companies created many sophisticated mechanisms allowing them to transform information during transmission, and implement a variety of business and data transformation rules. While the technologies to synchronize data between multiple databases and enterprise systems are mature and sophisticated, the biggest disadvantage of these technologies is still data silos. When we take a piece of data (BOM, document, etc.) and transfer it from one system to another, we remove the ability of systems to work with real (live) data. Multiple copies of the data create synchronization problems and, as a result, the business value is diminished.

Internet and other modern database technologies developed a mechanism that allows to data to be shared and not copied between multiple systems and databases. From a process standpoint, a digital thread begins in one system and continues in another system linking different pieces of information together. Being able to do so without copy data from one system to another could be a big advantage.

Data Federation Technologies

By enabling data sharing and federation among diverse systems and applications, they are allowing businesses to make more informed decisions that lead to greater process efficiency and cost savings. With a digital thread, organizations can access a variety of product information simultaneously, like tracking materials usage or viewing real-time KPIs for machinery performance in one central place. Digital threads simplify communication between supply chain partners, making it easier to synchronize processes such as remote quality monitoring or factory analytics from multiple sources. All these advantages can be very beneficial if companies will figure out how to share and re-use data between systems without the need to copy data.

Data federation and data sharing are the technologies to support it. Federation of the data was invented quite some time ago and it is a mechanism that allows one system to “use” the data from another system using proxy and data queries across systems. The mechanisms can be different but involve multiple levels of APIs and data definitions combined with data caching and data retrieval. Data federation allows data from multiple systems (databases) to appear like they are located in a single database for query and retrieval.

Data sharing is becoming very popular these days with the introduction of multiple systems that includes “share” capability as one of the fundamental functions (eg. Google Docs, etc.). These methods quickly became popular and widely adopted by applications and companies. Data sharing allows users to get access to a specific set of information based on access control. It became very popular from the “document-centric” system standpoint. A similar approach is used also in many business systems sharing “data” and not actual documents.

Single Tenant vs Multi-Tenant Systems

A very important element of data integration in the digital thread is the ability to control the belonging of the data to different data sources and also to different companies. The data access across multiple companies in PLM systems and integration of data silos in a single thread between multiple companies is becoming really critical as the manufacturing industry is moving to a network fashion. Product lifecycle management spans multiple companies and existing data is located in multiple data management systems and source data systems belonging to multiple companies.

Most existing PLM systems in production today are single-tenant systems and it is a significant disadvantage because it limits everyone in the way data can be managed, controlled, and integrated.

Conclusion:

From the standpoint of Digital Thread, both federation and data-sharing technologies are the next steps in the journey of making data available and linked (connected). By allowing data to be linked and not syncing between multiple databases, systems are creating a digital thread as a continuum of the data located in multiple systems and belonging to multiple companies. The evolution of multi-tenant data architectures allows to companies to share it across company borders and not to export/import it between multiple systems. The PLM industry demands advanced data integration and data sharing mechanism allowing data consumers to get access to the data everywhere regardless of what company it belongs to without the need to develop complex data synchronizing processes. Making it happen requires a modern federated data model allowing data virtualization and sharing of all the data from different product lifecycle stages and companies. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital cloud-native PDM & PLM platform that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.