The topic of “intelligent part numbers” (IPN) came across again. This time it caught my attention via the post on LinkedIn from PLM Technology Group. The post links to the article – PLM and Configuration Management Best Practices: Part Numbers from PLM Advisors. The topic is really important and, especially, since it was marked as “best practice”, I thought I will share my thoughts.

Before continuing, I’d really recommend you read comments in the LinkedIn discussion thread. They are very thoughtful and, in my view, very conclusive. Here is my favorite comment from Wendy Baker:

I’ve been implementing and managing PLM systems for 20+ years. Just because you CAN doesn’t mean you should. Intelligent part numbers are only intelligent to the people that created the system, and for about 2 yrs before they get bastardized. And, how do you use items that have a product line/ product code on the next product? Many items already in a system can be used in a new product design, saving time and money. Also, if using PLM no need to buy revision in a part number. The example is so antiquated

Intelligent part numbers were born back in time when the document (even a paper document) was king in engineering and manufacturing. Therefore, they have been used as a tool to describe components and include all data in this “intelligent” code.

We are in the digital age of information management now. This is the time to follow the digital way to define information in a semantic fashion. Despite their long-held reign in the realm of engineering and manufacturing, intelligent part numbers (IPNs) are now a liability in the era of digital transformation exactly how it was described in the comment above. The advancement of data management technologies and the growing complexities of global supply chains have revealed the inherent limitations of intelligent part numbers. Here, we will explore why IPNs are becoming obsolete and why a shift toward more flexible and advanced data management practices is necessary.

The Downside of Intelligent Part Numbers

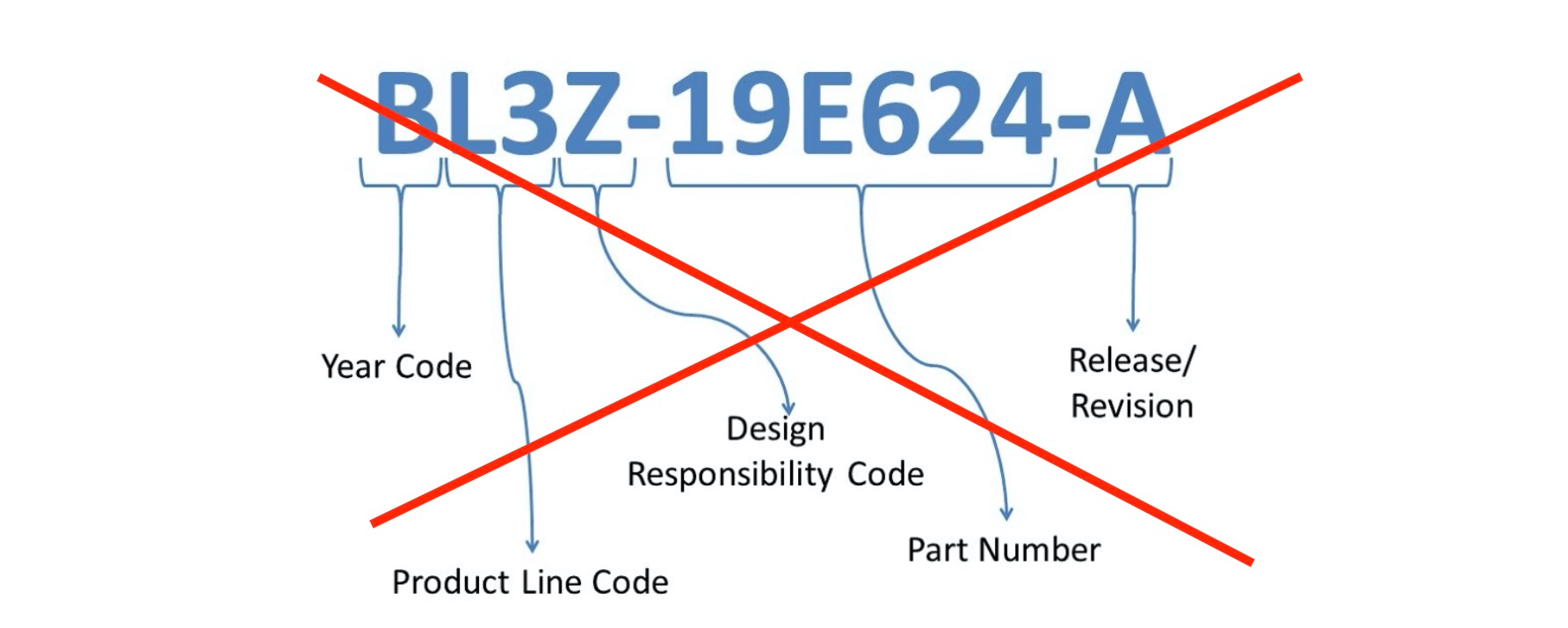

Intelligent part numbers, or significant part numbers, are identifiers that not only distinguish a part, but also carry embedded information about the part’s characteristics, such as its type, size, material, or its place in a sequence. While this method might have been practical in the era of paper-based catalogs and manual record-keeping, it is less suited to modern data management for several reasons:

- Limited Flexibility: An IPN system ties the identity of a part to its specific characteristics. However, when those characteristics change – as they often do in the dynamic environment of manufacturing – the part number also needs to change. This results in a cumbersome and time-consuming process of updating documentation and systems. Think about new product codes or changes. You should be able to re-code everything in a flexible way. You cannot do it with “intelligent” part numbers embedded everywhere.

- Legacy Dependency: IPNs require insider knowledge to decode the information they contain. This can lead to confusion and errors, especially when working with external stakeholders like suppliers and customers who may not understand the numbering system. Moreover, this dependency on specific individuals who understand the IPN system can become a bottleneck in operations. Even more, in the world of SaaS, these IDs are becoming really hard to manage for integration purposes.

- Scalability Issues: As businesses grow and diversify, the complexity of “intelligence” in these part numbers increases exponentially. This can make it hard to add new categories of parts or adapt to changes in the business, making the system less sustainable in the long run.

- Barriers to Automation and Digital Transformation: Intelligent part numbers pose a significant challenge to implementing automation. SaaS software, especially works with REST APIs that better use modern classification methods using semantics rather than strange codes from the past defined 30 years ago. They require human interpretation, which hinders the seamless integration of systems and processes, a key aspect of Industry 4.0.

The Benefits of Simple (non-intelligent) Part Numbers and Semantic Data Management

On the other hand, a system that uses simple (non-intelligent) part numbers – identifiers that don’t carry inherent meaning about the part’s characteristics – combined with semantic data management techniques, can overcome these issues. Here’s why:

- Enhanced Flexibility: simple part numbers allow parts to change without needing to alter the part number. This flexibility reduces the administrative overhead associated with part modifications.

- Universal Understanding: simple part numbers can be used for reference and can be automated and combined with rich semantic information, eliminating confusion and reducing errors. They don’t require specialized knowledge to decode, breaking down knowledge silos and enabling smoother collaborations.

- Scalability: With simple Part Numbers combined with semantic information, businesses can grow and diversify without the need to revamp the entire numbering system. This simplicity enhances the system’s adaptability and sustainability.

- Facilitating Automation and Integration: Simple part numbers work seamlessly with modern data management systems, APIS, enabling automation and making it easier to integrate systems and processes. This enhances efficiency, accuracy, and speed, and is in line with the principles of Industry 4.0.

Conclusion:

Intelligent part numbers were introduced because engineers and manufacturing companies did not have computers. Thus, the role of intelligent part numbers was to help everyone understand everything about an item based solely on its part number. However, as we move towards digital transformation, with connected tools and digital threads, the necessity for intelligent part numbers is dwindling. Even more, intelligent part numbers lead to data and process management complexity that cost a lot of money down to the road, and companies pay for these mistakes later.

While intelligent part numbers might have been beneficial in the past, they are becoming a hindrance in the modern era of digital transformation in engineering and manufacturing. As businesses embrace advanced data management technologies, the shift from intelligent part numbers to modern semantic data management is inevitable. This transition will facilitate better flexibility, understanding, scalability, and automation, setting businesses up for success in the ever-evolving industrial landscape.

So, in my honest opinion, intelligent part numbers must be replaced with simple numbers and attributes capable to describe all information (in your example – year code, product code, design responsibility code, etc). When will this change completely? That’s a good question… because while technology adapts easily, people often do not.

Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital thread platform including PDM/PLM and ERP capabilties that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.