PLM (product lifecycle management) have a reputation as a complex IT project. During my two decades of experience with PLM implementation in different roles, I learned that a PLM project always requires substantial effort from all involved parties – software vendors, implementation service providers, and customers. And PLM projects have high mortality rates. If you have a different opinion, please send me an email – I want to talk to you.

Why do PLM implementations fail?

How many PLM projects fail? I didn’t find a quantitative answer to this question. I found tons of publications speaking about it. Here are some of them.

13 Common PLM Implementation Problems and How To Avoid Them via SharePLM

The PLM Blame Game via Jos Voskuil (aka Virtual Dutchman)

Why do PLM Implementations Fail? via Lionel Grealou

Why do PLM Projects (Still) Fail? via ProSTEP iViP and Martin Eigner

PLM implementation success rate in SME – research via Bas Koomen and CADMES.

5 Attitudes That Can Kill PLM Projects via Beyond PLM.

According to Bas Koomen’s research, the number of failed PLM projects is at least 50%, although they didn’t find a statistical confirmation of that. Here is the passage:

A general problem with PLM implementation is that many projects fail to achieve the project goal. Some authors claims a failure rate of 50%, but no further sources are mentioned [3, 7, 8]. Moreover, industry surveys show that companies struggle to implement PLM successfully [9]. While this is a problem for large companies, it is a considerable risk for SMEs. The relative cost of a PLM implementation is higher for SMEs because the fixed part of the investment is divided over fewer people.

According to Jos Voskuil, the failure rate and publications about PLM failures are because these stories “sell better”. At the same time, he said that although not considered as a “failure” many PLM implementations are behaving differently from anticipated.

I can publish a failure story for every PLM vendor if I want. However, the reality is that the majority of PLM implementations do not fail. Yes, they can cause discomfort or friction in an organization, as implementing the tools often forces people to work differently. And often, operating differently is not anticipated by the (middle) management and causes a mismatch in the people, process & tools paradigm.

The horror stories like this one – Telecom Giant Ericsson Halts Its PLM Project with Dassault’s 3DEXPERIENCE can be found for each vendor, but they outline typical problems – bad planning, technology not ready, underestimated the complexity of product-related data migration, conflicts between vendors and implementations, and many others.

IT Project Failures: Rates and Reasons

While I didn’t find specific stats about PLM implementation failures, I found very interesting IT project failure rates – IT Projects Failures Rates: Facts and Reasons. Check this out.

According to the Standish Group’s Annual CHAOS 2020 report, 66% of technology projects (based on the analysis of 50,000 projects globally) end in partial or total failure.

31% of US IT projects were canceled outright and the performance of 53% ‘was so worrying that they were challenged.

Research from McKinsey in 2020 found that 17% of large IT projects go so badly, they threaten the very existence of the company

BCG (2020) estimated that 70% of digital transformation efforts fall short of meeting targets

Here are the top 5 reasons why IT projects failed:

- Business questions were not asked about values, satisfaction, and delivery timeframe.

- The business cases are lacking and the project scope is poorly defined

- People back away because of other priorities

- Bad project management

- User requirements remain unclear

I can certainly see the common line between many PLM project failures and this IT project research.

Unstoppable PLM Playbook

When I started my blog back in 2008, one of my goals was to share my PLM knowledge and provide a public source of information where everyone can learn about PLM. The world was a different place 15 years ago. Today, you don’t need to go to the conference to get materials about PLM software. Information is provided by vendors and the number of people writing and sharing information about PLM has grown tremendously.

How to learn to implement PLM? I wrote about it in my earlier article – PLM playbook: how to learn about PLM? While I’m still happy to share my knowledge and experience, I think there is a bigger need in helping manufacturing companies and, especially PLM professionals, with the methodology of how to achieve the right goal when implementing PLM. Which made me think about the Unstoppable PLM playbook ©.

I found a similar passion for helping companies to adopt PLM while talking to Helena Gutierrez. Over many conversations during the last few months, we talked about how to help manufacturing companies with PLM adoption. The unstoppable PLM playbook is still a work in progress, but we want to start talking about it to get your feedback and start the conversation.

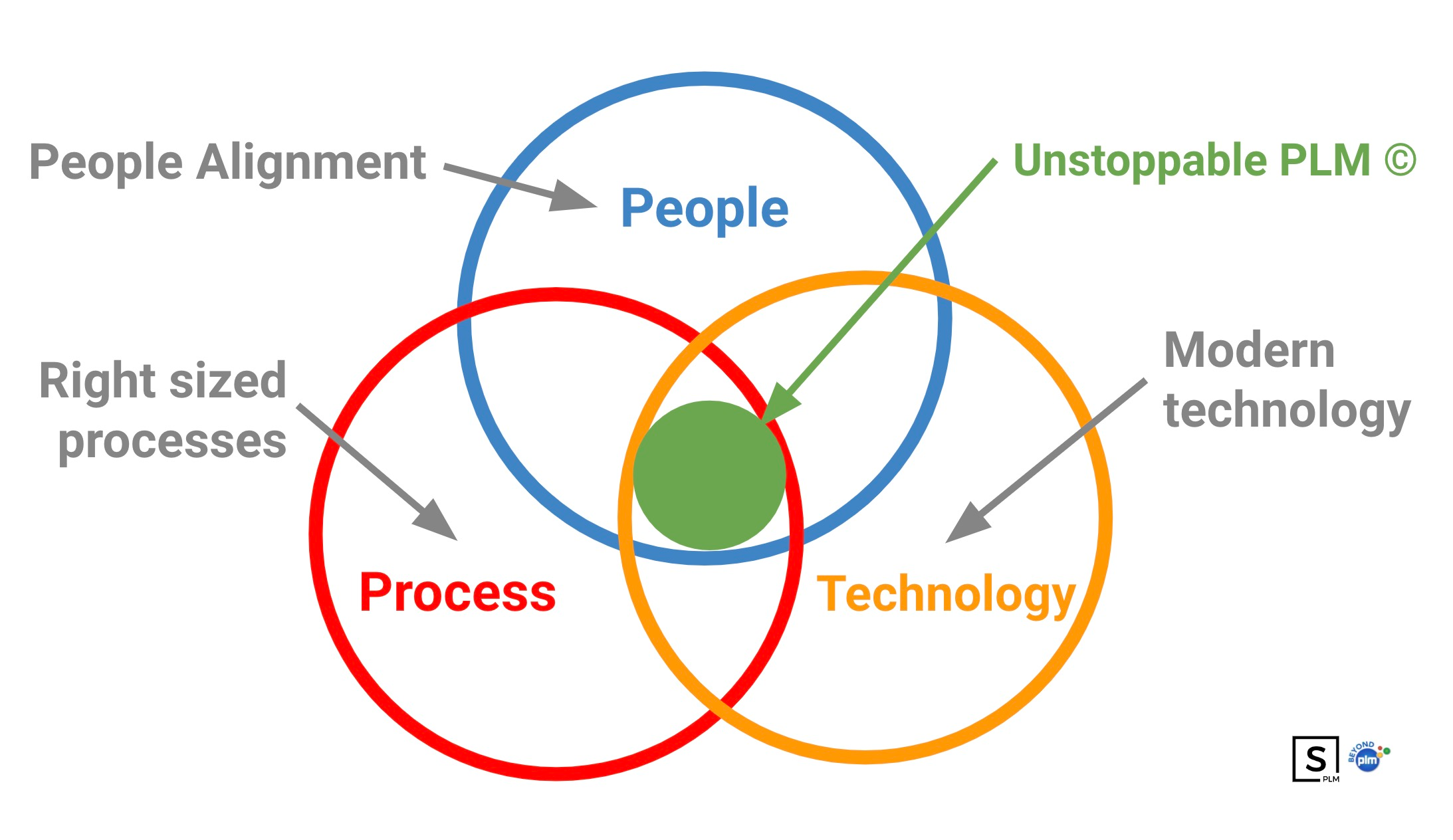

The success of PLM implementation is in the intersection of three domains – (1) Process; (2) People and (3) Technologies. While you can find many publications about it, I found building a specific implementation plan is a place where most companies small and large are usually struggling.

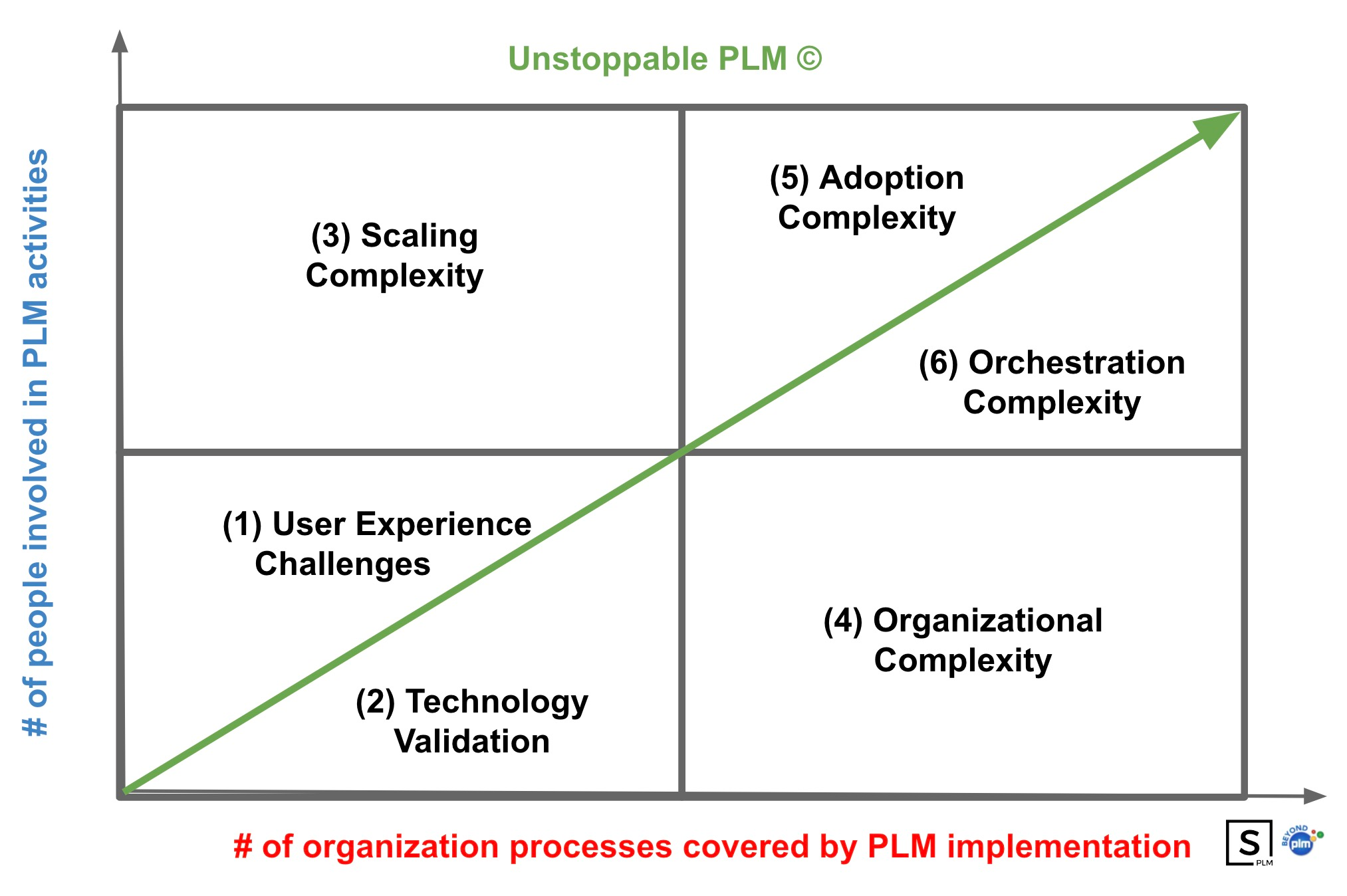

I like 2×2 diagrams. They always can help to clarify the issue and find the right methodological approach. Here is a diagram that can be used to understand the complexity of PLM implementations in any organization. It is a very high-level playbook for any organization, but this is where you should start your unstoppable PLM journey.

What is my conclusion?

Implementing PLM is not a simple thing. Depending on the organization, project scope, and objectives, it is a serious project that requires planning and management. Companies often think that they are very different in the way they need to implement PLM. While it is true, I found a very common set of rules and logic about how to achieve successful goals in the implementation of PLM. I like 2×2 diagrams – they help a lot to understand the nature of the problem. The diagram above helped me a lot in many implementations to understand how to address a specific company’s needs and how to work toward a successful PLM playbook for each specific company. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital thread platform including PDM/PLM and ERP capabilities that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.