PLM projects are famous for their complexity and failures. How to turn your PLM implementations from a state of uncertainty and disaster to a state of measurable and accelerated growth. This is my fourth (and probably last) article in the series of works outlining core principles of PLM implementations that can help you to organize your PLM strategy and turn it into a successful implementation with tangible results. If you missed my previous publications, please check them out.

PLM Playbook: How to learn Product lifecycle management?

PLM Project Failure and Unstoppable PLM

How To Make PLM Simple, But Not Simpler?

PLM: A Different Name for Your Daily Routine

If you’re engaged in the production and manufacturing sector, chances are you’re already incorporating fundamental elements of product lifecycle management (PLM) into your workflow. In the course of creating CAD designs, maintaining version control, producing Bills of Materials, and facilitating collaborative efforts with manufacturing and suppliers, you are effectively implementing PLM, often without labeling it as such.

Originally, the term PLM was introduced by engineering software providers and large corporations, such as aerospace and automotive manufacturers, Its purpose was to streamline and organize change processes within engineering and product development departments. It’s crucial to note that it borrowed heavily from pre-existing configuration management practices used by these industries.

Therefore, I have good news for you. If your company is producing and shipping something (eg. physical products), you do have PLM. It can be poorly organized and use the wrong tools and technologies. It can be a paper tray, files and folders, Excel spreadsheets, or some form of database and data management. But you have it because, without it, you won’t be able to do anything.

PLM Implementation Mirage In Dessert

Years ago, I was leading a team of engineers for a project with a large telecom company. With a tight timeline and a laundry list of features to implement, we were under significant pressure. The director pointed out that endless development and improvement of features can turn a project into a mirage — a goal that can never be achieved.

This concept reminded me of many Product Lifecycle Management (PLM) projects I’ve seen over the years, where companies start initiatives without a clear completion strategy. They continually add new requirements, features, and technologies, without a defined endpoint. Consequently, PLM often becomes synonymous with expensive, complex, and extensive projects that try to cover too many aspects. Sales tend to overstate what PLM technology can achieve and unrealistic expectations are set.

So, how to change these bad practices? How to rethink the PLM approach in product development, engineering, and manufacturing processes. A product is never truly complete, and continuous development should be seen as a necessity rather than a hindrance. In the same vein, PLM should be viewed as a series of iterative deliveries that progressively improve the product, manage data, enhance communication, and refine the manufacturing process and customer experience.

A successful PLM project, then, is more like a journey from one oasis to another in a desert, moving from point to point, and achieving goals along the way. This approach prevents PLM from becoming a mirage, a goal forever out of reach, draining resources and delivering no returns.

Agile PLM Implementation Processes

For the last two decades, agile methods because de-facto a norm in software development practices. Especially when combined with cloud and continue integration (CI), these product development processes create a huge competitive differentiation for these organizations and improved the way technology products now can be developed and delivered to customers.

For the last 10-15 years, I was managing teams and being involved in agile product development of PLM products and PLM implementations as a consultant and in my role as a software vendor. I learned multiple lessons about how to make these implementations successful in small and large industrial companies. I also learned how to avoid mistakes and use different measurements to improve engineering and production processes.

During the last year, I discussed many of these concepts with Helena Gutierrez. She is leading a boutique consulting company specializing in change enablement for PLM implementations. Together we are looking at how to share our experience and approach to help companies to use modern technologies and implement PLM systems.

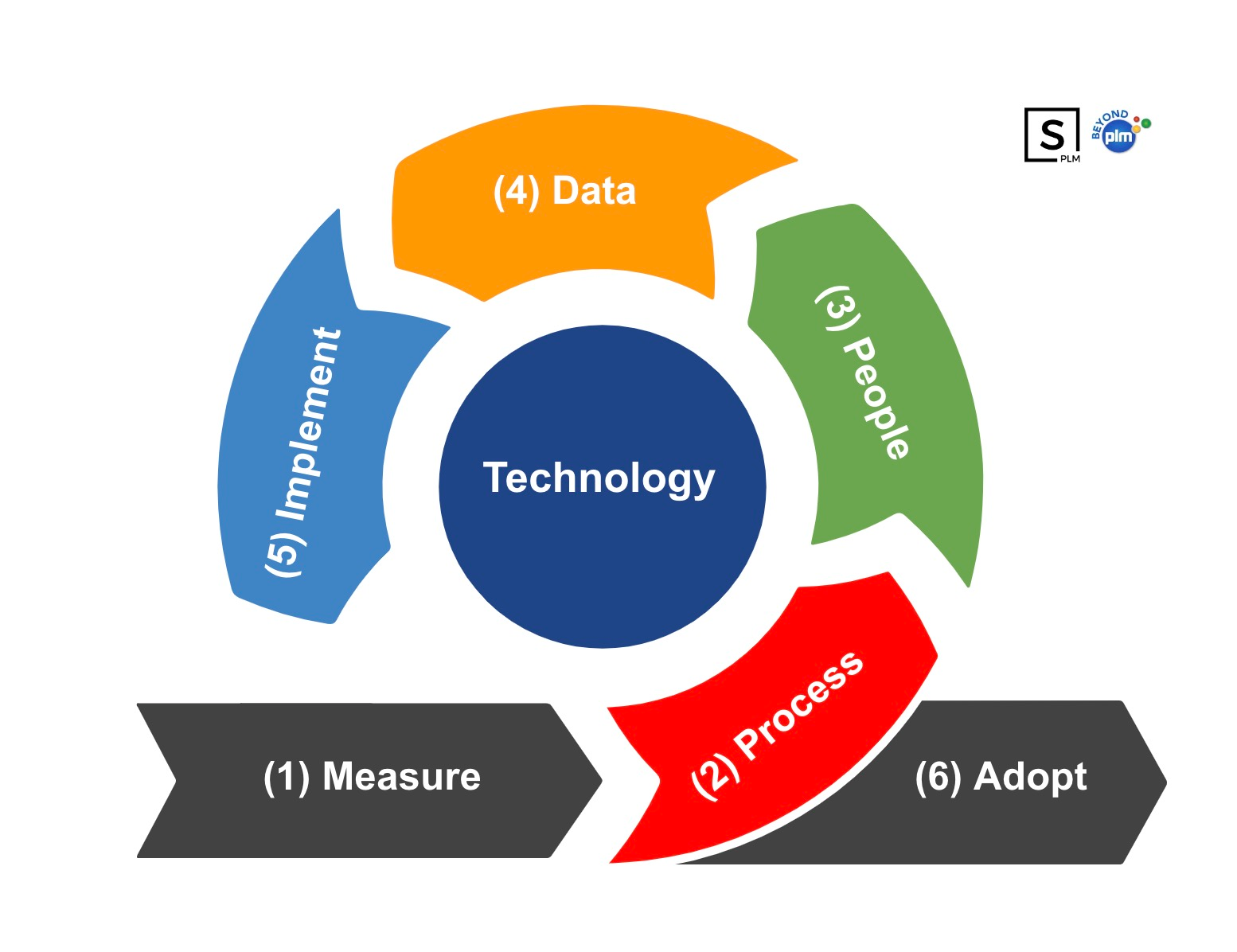

In my article today, I want to share a summary and recommendation of the following 6-step process management best practices that can help you to manage PLM implementations. The foundation of this approach is a sprint-based (phased) approach. Fast iteration combined with these best practices gives a great outcome based on the experience I had.

The following picture gives you a framework that can help you to define your tasks when implementing PLM in any organization. Keep in mind that the picture describes one sprint, and the idea of it is to be repeated many times.

PLM Technology

The foundation of any data and process management is technology. When I say technology, I mean any technology. From my standpoint, you can decide to use file storage, Excel, and emails. It is unlikely to become a successful PLM implementation, but it will be your technological decision point. Of course, better technological advancements will bring better implementations potentially.

Measurement and KPI

You cannot effectively manage any process without measurement and KPIs. These KPIs are absolutely important for any organizational process. Therefore the foundation of any PLM implementation is KPIs you can bring and business processes that can be described using these KPIs. It can be anything – damaged CAD files, lost BOM Excels, absence of traceability, and many other things. But KPIs are absolutely important to create a solid foundation for PLM implementation.

Process

Capturing a process to improve is the first step. You really need to focus on a specific process that must be improved, don’t focus on PLM Holy Grail. Consider it as a “process” that will be improved in the current “PLM sprint”. You would like to have many such implementations done. Think more about sprints and small steps.

People

Once you identified the process, getting an alignment with people that are involved in this process is absolutely important. You need to get approvals and buy-ins from key department leads (at least) to being PLM implementation curation to a desired level.

Data

We live in a digital world and, therefore you need to keep the focus on how to manage data in the most comprehensive and intelligent way to support activities. Technology is, of course, where you start, but what is important is to put data at the center of the business and strategy.

Implement

Companies are looking into implementation as an important step in the achievement of successful PLM-driven processes. However, don’t turn it into a regular procedure- make it different, and help companies to learn what to do.

Adopt (and Onboard)

Even the best PLM implementation needs to be adopted, nothing will happy by itself. It is hard to get systems adopted where they are complex and requires multiple configuration steps. Adoption includes multiple aspects (1) process implementation, (2) organizing KPIs, and (3) measurement of what can be improved next.

What is my conclusion?

PLM implementations are complex processes and require dedication from both vendors (implementation teams) and customers (people that are going to adopt the technologies and everything that is related to them). Without appropriate preparation and strategizing, you can find yourself in a PLM implementation gridlock. Our experience with unstoppable PLM implementations will help you to achieve better results. Stay tuned…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital thread platform including PDM/PLM and ERP capabilities that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.