The manufacturing industry is transforming and digitalizing. Managing data is becoming extremely important in the modern digital world. In the old fashion pre-digital environment CAD systems were fully relying on files and managing data was totally dependent either on how to manage CAD files/ Excels or to deployment of PDM and later product lifecycle management systems. PDM/PLM was complex and annoying for engineers. CAD companies were acquiring PDM vendors for the last 15-20 years and practically eliminated independent PDM businesses. But even so, each CAD vendor has now a dedicated PDM system, engineers don’t like them and consider them as a very annoying but necessary thing.

For the last 10 years, we can see a growing trend in cloud CAD systems and PLM software. Those systems came with the idea of embedding PDM functions into CAD systems and making data management a breeze. But managing derivative information coming from CAD systems in the way of product data, neutral geometry files and other pieces of information needed to manage product development and manufacturing is not disappearing and even becoming more important since traditional mechanisms of sharing CAD designs are not available with cloud systems.

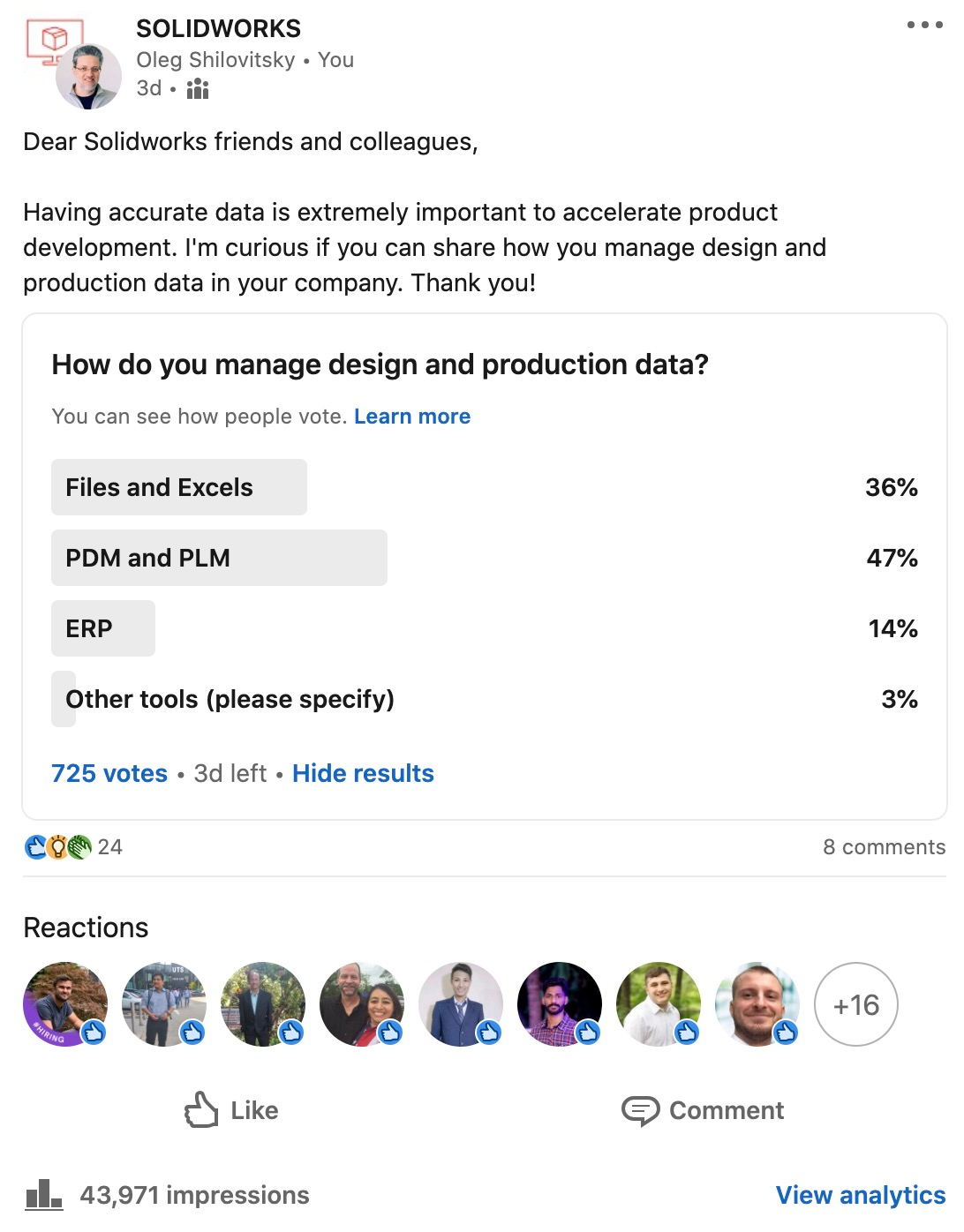

Earlier last week I created a poll asking LinkedIn Solidworks group about how they manage data. It is still active – you can navigate to this link and check. Below you can see some preliminary results with a few hundred votes.

You can see an interesting distribution with a large number of voters saying they use files and Excel to manage the data. One of the comments caught my attention and questions. It was related to cloud-native vs cloud-hosted CAD systems. I found this comment and link to Onshape’s article “The Difference between Cloud-Native and Cloud-Hosted systems very interesting.

In the growing number of cloud CAD systems (eg. Onshape, Autodesk Fusion360, Alitum 356, 3DEXPERIENCE xDesign, and a few others), the most interesting question for me is how these systems will interoperate together, but even more, how downstream product development and manufacturing processes will be managed to get access to a full design digital thread including mechanical, electronic and software data.

Before answering this question, let’s dive into the details of cloud architectures to understand how cloud-native CAD applications can make a difference by eliminating data management hurdles and, at the same time, why it might not solve one of the most fundamental data management problems of data accuracy.

Understanding the Basics of Cloud-Native and Cloud-Hosted Applications

In the evolving landscape of cloud computing, two terms often come into focus: “cloud-native” and “cloud-hosted.” Both models represent ways to leverage the cloud’s power, but they differ significantly in implementation and philosophy. Before we dive into the debate, it’s essential to clarify what these terms mean.

Cloud-Hosted Applications

Cloud-hosted applications are typically traditional software applications that have been migrated to the cloud. This practice is known as “lift-and-shift,” as the existing application, initially designed to run on-premises, is lifted from its current environment and shifted to a cloud platform.

Although this approach allows businesses to take advantage of basic cloud benefits like cost reduction, scalability, and improved availability, it doesn’t fully leverage cloud capabilities since the application was not initially designed for the cloud environment.

Cloud-Native Applications

Cloud-native applications, on the other hand, are designed and built specifically for cloud environments. They are developed using a collection of small, independent, and loosely coupled services, also known as microservices. These applications take full advantage of cloud principles like automated scaling, easy recovery, distributed development, containerization, and DevOps practices.

Cloud-native applications are built to exploit the cloud’s potential fully, providing flexibility, robustness, and scalability that are simply not possible with cloud-hosted apps.

Cloud-Native vs. Cloud-Hosted: The Traditional Debate and What’s Coming Next?

Traditionally, the debate has centered on whether it’s best to ‘lift and shift’ applications to the cloud or build applications specifically for the cloud environment.

A cloud-hosted approach might seem faster and less costly initially because it avoids the time and resources needed to redesign and rewrite applications. But in the long run, those systems are still managing data in the same way they did with on-premise. In the case of CAD, it is a file-based system. Cloud-native applications are more scalable, resilient, and agile, making them better equipped for today’s fast-paced digital landscape.

However, the most interesting point to me related to cloud CAD applications is related to how cloud CAD (both hosted and native) are managing design data. What we learn from different architectures is that all cloud-native CAD systems have developed a way to store data in the database, rather than use a traditional file system. Which from one side, solves the painful PDM problem, but on the other side, creates another silo (for example for mechanical design and PCB design). We will come back to this point later.

Is the Cloud-native vis Cloud-hosted Debate Still Relevant?

Yes, the debate remains relevant. As businesses increasingly rely on cloud services, the decision between going cloud-native or cloud-hosted can significantly impact operational efficiency, scalability, and even the bottom line. Companies need to weigh their short-term needs against long-term goals. If they require an immediate transition to the cloud without a large upfront cost, cloud-hosted solutions might suffice. However, for organizations with a long-term vision that involves scaling, evolving, and remaining competitive in a digital-first environment, cloud-native could be the optimal choice.

From a CAD data management standpoint, the real question if cloud-native CAD applications can solve two fundamental problems of data management – (1) a single source of truth (design database); and (2) interoperability, which is absolutely needed for modern complex development where all systems (mechanical, electronics, software) are intertwined and focus on the integration of business systems and entire product development process.

Stressing the Importance of Integration and Openness in Cloud-Native Applications

While cloud-native applications offer various benefits, they can become even more powerful when they embrace integration and openness. Integration refers to the ability of these applications to work seamlessly with other systems and services, while openness refers to using open standards and technologies. All cloud-native systems are using REST APIs, which is a de-facto standard in cloud applications. By doing so, the question of data interoperability is removed (as long as these systems provide APIs).

However, it brings many other questions related to product data management, supply chain strategy, and entire product lifecycle. In an ideal world, an integrated cloud-native architecture allows organizations to leverage different technologies and services simultaneously, providing a highly adaptive environment that can quickly respond to changing business requirements. But in reality, the integrations in the pre-cloud file-based CAD systems were solved by accessing CAD files and getting the data, today requires a new way to integrate data from multiple cloud-native CAD systems and make this data available downstream for decision making.

What is my conclusion?

The industry is transforming from managing data using CAD files and Excel spreadsheets into a digital form. It is triggering the question of how modern manufacturing is integrating computer-aided design, PLM systems, and an entire set of business processes into an entire single digital system. The product development process is complex and requires the interaction of multiple teams, focusing on design, production and manufacturing planning, procurement, and many other activities. The efficiency of the collaboration and effectiveness of decision support bring the demand to get accurate data, recombine data sources (eliminate silos) and give to product development team access to accurate data at any moment of time.

Ultimately, supporting agile product development workflows using cloud-native applications can be a winning element in this ongoing debate. As organizations look to innovate at speed while maintaining high service levels, the cloud-native approach is hard to beat. However, products are becoming more complex and require the integration of multi-disciplinary design data sets and using this data for production planning and procurement. Native-cloud CAD is another silo. Alone, it won’t solve the problem. It will help to eliminate CAD files, but then customers will be looking at how to get all data sets (BOMs, derivatives such as STEP, PDFs, DXF, etc) and integrate all digital information about the product design together. There is a need to have other cloud-native tools capable to combine design data into business outcomes – data sets, bills of materials, RFQs, purchasing orders, to contact contractors and suppliers.

Cloud-native CAD is a big step in eliminating CAD files and replacing old fashion PDMs. But these systems are just one step in the overall holistic process of digital transformation. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital thread platform including PDM/PLM and ERP capabilities that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.