The industrial world is changing and so product lifecycle management (PLM) software. Back decades ago, PLM software was only for large defense, auto and aero companies building gigantic programs and it required millions in investment. Things are changing and manufacturing landscape is different from what was 15-20 years ago.

Product Development and Manufacturing Is Changing

A few things happened since then. Here are the three important drivers for change:

- Product and process complexity. We build more complex products that includes different components and entire systems. A small toothbrush has now a micro PCB board, embedded software and it connects with the cloud services and sending notifications to your mobile devices recommending you how to optimize your dental care. Before, it was 7 parts assembly made from plastic and now it is a complex system.

- Product development process is getting more complex, it requires more people to be involved, those people are working in different places and needs to be connected, get the right information at the right time and being notified when something goes wrong

- Demand for speed is skyrocketing. What was taking a year a decade ago is now squeezed to a month. Companies are pushed into an unprecedented stress for time, competition, regulation and supply chain turbulence.

So, companies need a different product lifecycle management to support business processes with the modern manufacturing environment. Product’s lifecycle is shortening, designing and building products requires an integration of multiple disciplines and tools together. It is different from your “grandpa PLM circa 1990s”.

PLM Software Industry Is Changing

There are many changes the world of software vendors building PLM software. The technological change is unprecedented. The amount of new technologies to help to build new type of PLM software is growing. Two decades of building SaaS software is fueling PLM software industry with new tech and new ideas. Check one of my recent articles on Engineering.com – Graphs Map the Future of PLM Software. But there are many others – database, cloud, AI and others.

PLM Software Selection Process Is Changing

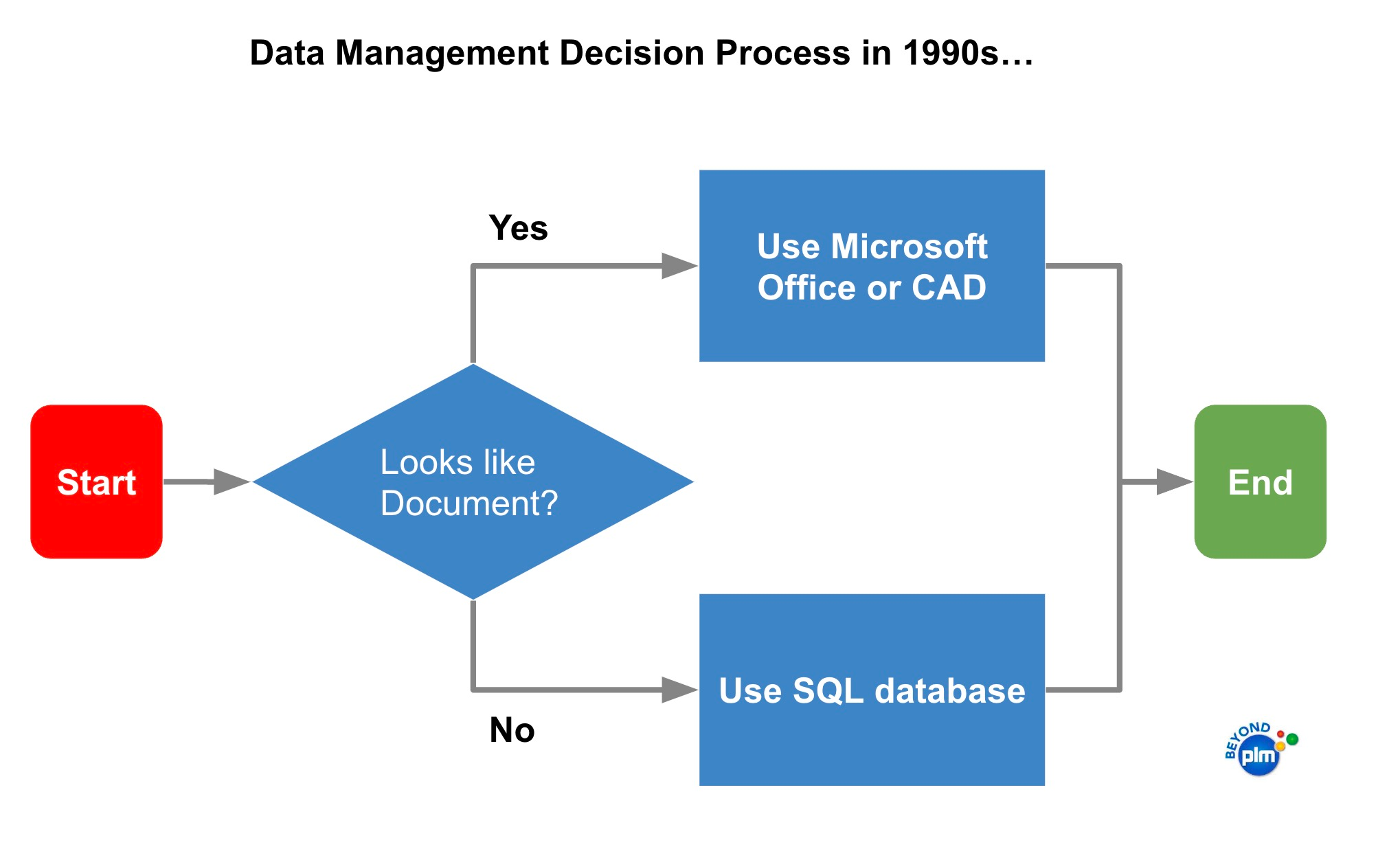

The process of selecting PLM software is changing too. Years ago, the process of PLM selection was easy and similar to this graph – (1) use Microsoft Office or (2) Use PDM system from CAD vendor.

The world is changing industrial companies are disparately looking for help to choose the right technology. So, pressure goes up, the management is looking for answers and engineers and IT people are looking how to make the right choice.

While “buying from IBM” can be still a right approach for some companies to reduce risks and promise to themselves a bright PLM future, the number of large PLM projects that failed (even after purchasing latest and greatest stuff from big 3 PLM software vendors) and, also, the type of companies I described above (agile, nimble and innovative) are not finding themselves in a good position to buy “another CAD file data management with fancy document management workflow capabilities”. They need more.

Having a strategy when selecting a PLM system is important. Although you might find many options to select PLM system, when it comes to the real selection, companies are selecting from a dozen products and after additional slice and dice, focus on 3-4 systems that fit their needs. In my work with many customers, we found that elements of an unstoppable PLM playbook can be used to go from an abstract set of requirements to specific needs your company has.

Top 7 PLM Software Selection Mistakes

I want to focus on very typical mistakes that I’ve seen industrial companies are making when approaching the process of PLM software selection. The list below is my “7 Don’t” you want to follow before acquiring ANY PLM software in 2023.

Mistake 1: Don’t spend time on the requirements about what you need.

Mistake 2: Assume “one size fits all” and looking at big players with large solutions

Mistake 3: Buying “cloud PLM marketing” promising all advantages of mature solutions on the cloud

Mistake 4: Not running a trial with the software and checking it “first hand”

Mistake 5: Thinking that “legacy data” will magically move to a new system

Mistake 6: Not defining internal “PLM roadmap” with milestones

Mistake 7: Acquiring PLM solution for the next 20+ years

I will speak how to avoid these mistakes and what to do in my next blogs. There are many other mistakes, but I thought narrowing to 7 is important.

What is my conclusion?

Product data management, product lifecycle management, supply chain management and other disciplines are important to ensure the company can functioning properly. But unlike 20 years ago, the software world is changing. You’re not looking into “system for department” like it was decades ago, you’re looking for services to support you in specific functions. This is a key change. It is less about how to ensure that all your data and files are located in a single place (although it can be nice), but about how to ensure that people have an access to this data online (and not exporting Excels from a large PLM database because it is not available without VPN or licenses are too expensive).

The world is changing and so PLM software is changing too. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital thread platform including PDM/PLM and ERP capabilities that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.