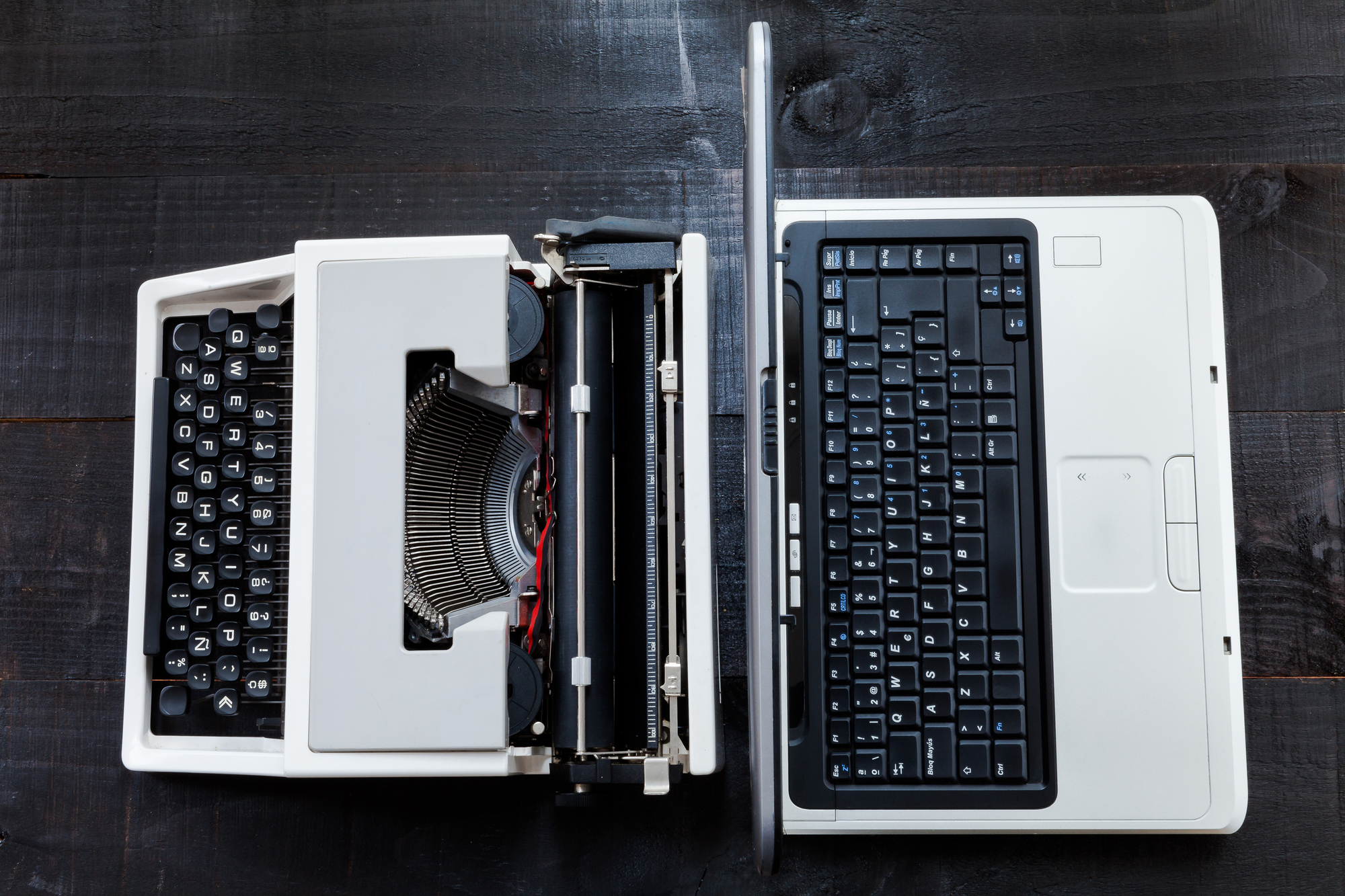

In the digital transformation era, the implementation of Product Lifecycle Management (PLM) systems has become a cornerstone for manufacturing and engineering companies striving for innovation and efficiency. However, the journey toward fully leveraging PLM technology often presents a paradox that hinders progress. The conventional wisdom—endorsed by PLM vendors and consultants—that adopting a PLM system necessitates a comprehensive transformation of business processes has led to a catch-22 situation. Companies find themselves in a deadlock, unable to move forward due to deeply ingrained process inefficiencies, often resorting to rudimentary tools like Excel, PowerPoint, and emails for data management and collaboration.

This dilemma was recently highlighted by Adam Keating’s observation:

“Several times in the past two weeks, I’ve heard ‘We can’t implement CoLab Software right now; we need to fix our process first.'” This statement reflects a widespread challenge within the industry, emphasizing the critical need for a shift in how companies approach PLM implementation.

I’ve heard about the same dilemma from our customers and prospects at OpenBOM. It is usually sounds like that.

“We are working very inefficiently using different homegrown tools, file storages, Airtable spreadsheets and a few legacy databases. We need to have some time to figure out our processes and how to manage our work. Once we decide how to organize the work, we will come and evaluate possible tools to help us.

Why Traditional PLM Approach Cannot Help You to Do More?

In the article today, I want to discuss one of the most critical problem many organizations have these days – how to achieve better results with more with less. We are live in the world that creates more expectations for what we need to. But we have limited resources. Manufacturing companies need to build a higher quality products faster and spend less resources. Better, Faster, Cheaper – this is where demand always being, but these days is extremely painful for many companies.

Old product lifecycle management (PLM), product data management (PDM) and document management tools offer your a business transformation strategy, which is good and important, but leaves you without tools that can efficiently brings you that point. The entrenched PLM tools are complex, resources thirsty, not robust and time consuming. Most of them were born 25+ years ago and relies on old database technology, single company architecture and demand re-thinking your processes without ability to be flexible. This is why it is important to bring new PLM solutions and PLM software capable to revert the process upside down and rethink how business systems can be used in product lifecycle.

Let’s talk about importance of processes and modern digital tools available today in the market.

The Importance of Processes

Processes are the backbone of any organization. Without well-defined and efficient processes, companies stagnate, unable to execute their strategies effectively. The traditional view that processes must be perfected before the adoption of a PLM system can inadvertently lead to paralysis by analysis.

In contrast, I believe in the potential for modern PLM technology to drive process improvement as part of its implementation. In an old joke, I called it “to build an airplane and fly it at the same time”. While it is a joke, of course, I think we can take it seriously. Modern SaaS platforms are never stop their development. Most of them are platforms that continues their development non-stop and improving what they do by providing new features and functions as well as adapting themselves by continues measurement and self-improvements. Moreover, modern AI research demonstrates the ability of system to learn and to improve as an outcome of system usage by a specific process and data.

This approach allows companies to evolve their processes dynamically, leveraging the insights and capabilities provided by the PLM system.

The Role of Digital Tools and AI

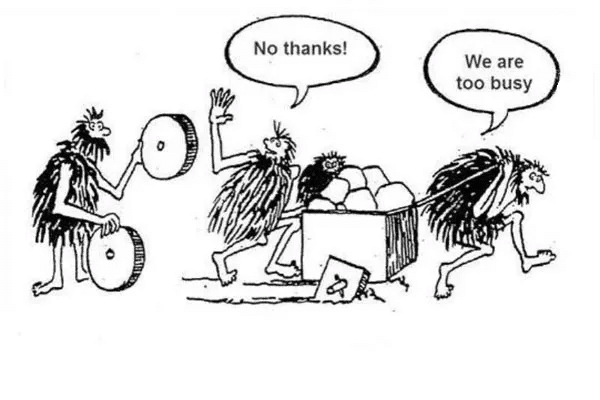

In a world increasingly dominated by digital technologies, the tools we use to manage processes and data are pivotal. Relying on outdated or simplistic tools like Excel and PowerPoint for process management is akin to seeing every problem as a nail when you only have a hammer.

I don’t know who is the author of this image, but it explains very well what I see in many companies that are struggling to improve their processes using old tools. Read more about it in my article.

Digital tools and AI offer the sophistication needed to handle complex processes, enabling more efficient organization and execution. By integrating these technologies into PLM systems, companies can redefine their processes in ways that were previously unimaginable, facilitating innovation and agility.

A New Type of PLM Technology and Role of AI

The key to overcoming the PLM implementation paradox lies in adopting a new type of PLM technology—one that is inherently designed to improve and fix processes from the outset. This technology should offer instant start capabilities, trial accounts, flexible data models, seamless integrations, and the ability to conduct quick pilot projects. Such features ensure that companies can experiment and iterate on their processes in real-time, without the need for extensive upfront process refinement.

AI brings an additional perspective in the world of PLM implementations. We are still at a very early days of AI, but you can see how it shifts the perspective. These days, I recommend to everyone before doing any task to “ask ChatGPT”. It is proven to be a good strategy to optimize any tasks you do. It goes forward because today, AI can perform tasks. I’m sure, modern PLM will be able to leverage AI after capturing data from a company and analyzing it. I will keep this topic for the next article. Stay tuned.

Conclusion

The journey toward effective enterprise system implementations to support product development such as product data management (PDM), product lifecycle management (PLM), enterprise resource planning (ERP) and customer relationships management (CRM) implementation does not have to be a choice between refining processes and adopting new systems. By embracing a new type of digital technologies and modern SaaS tools that facilitates process improvement as an integral part of its adoption, companies can escape the catch-22 situation that has plagued the industry. This approach not only accelerates the implementation of PLM systems but also ensures that the processes underpinning these systems are optimized for the digital age. It’s time for manufacturing companies and engineering teams to rethink their approach to PLM, moving beyond traditional paradigms to a future where process improvement and system implementation go hand in hand.

The path forward requires a balance between process refinement and technological adoption. I invite your comments and insights as we navigate this evolving landscape together. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital-thread platform with cloud-native PDM & PLM capabilities to manage product data lifecycle and connect manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.