I want to continue my first PLM Glue Technologies topic (#1 was about data). Sunday is good time to think about something big – such as Business Rules. Business Rules are often used to emphasize connection between organizational goals and operations. Since PLM in view expected 360 Degrees view on Product Lifecycle to have connection to organizational goals sounds very important.

Area of Business Rules technologies created by something called BRMS (Business Rules Management Systems), software allowed to define, deploy, execute, monitor and maintain wide set of business logic in organization. Over past few years significant consolidation on the market of business rules engines happened and several big enterprise software vendors as well as platform providers acquired or developed Business Rules offering. Finally companies consolidated into BRMS platforms (or part of bigger Application platforms) and Rules Engines Toolkits – some of them open sources.

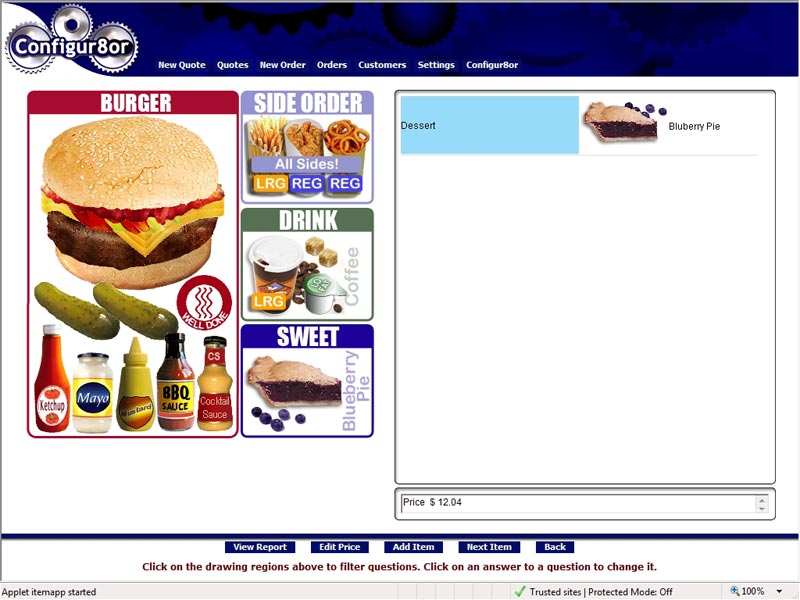

I think usage of Business Rules Systems together with PLM systems can bring more openness and clarity in the way product data managed in context with decision management. Such rules defined in external manner will allow to tailor PLM system behavior without too deep involvement into PLM implementation. But in order to do it PLM systems need to support level of openness for data to be used for rules. Possible areas to use BRE in PLM can be implementation of product compliance and regulation, Knowledge Based Engineering, product configuration and decision making.

Any comments? Does anybody have experience in bridging Business Rules Engines and PLM?