I was catching up on some PLM social media writing earlier today. Unfortunately, I was not able to attend PDT Europe this year, but one of my favorite PLM blogging colleagues Jos Voskuil did an excellent job by creating a summary of the conference in his two blog posts – Day 1 and Day 2. Check them out. I found it very informative.

Digital Transformation – Is it time to make your hands dirty?

Jos wrote in his blog about digital transformation – it is time for us to roll up our sleeves and get some work about it. He quoted Torbjörn Holm, co-founder of Eurostep, who addressed one of the bigger elephants in modern enterprise: how to deal with data? The main point I captured is that the amount of data is growing and it is becoming very hard to get the right data contextually presented at the right time for the right people. Another aspect and significant problem for data collection are that a large portion of the data is actually stored in documents and not really accessible by any data sharing and managing services.

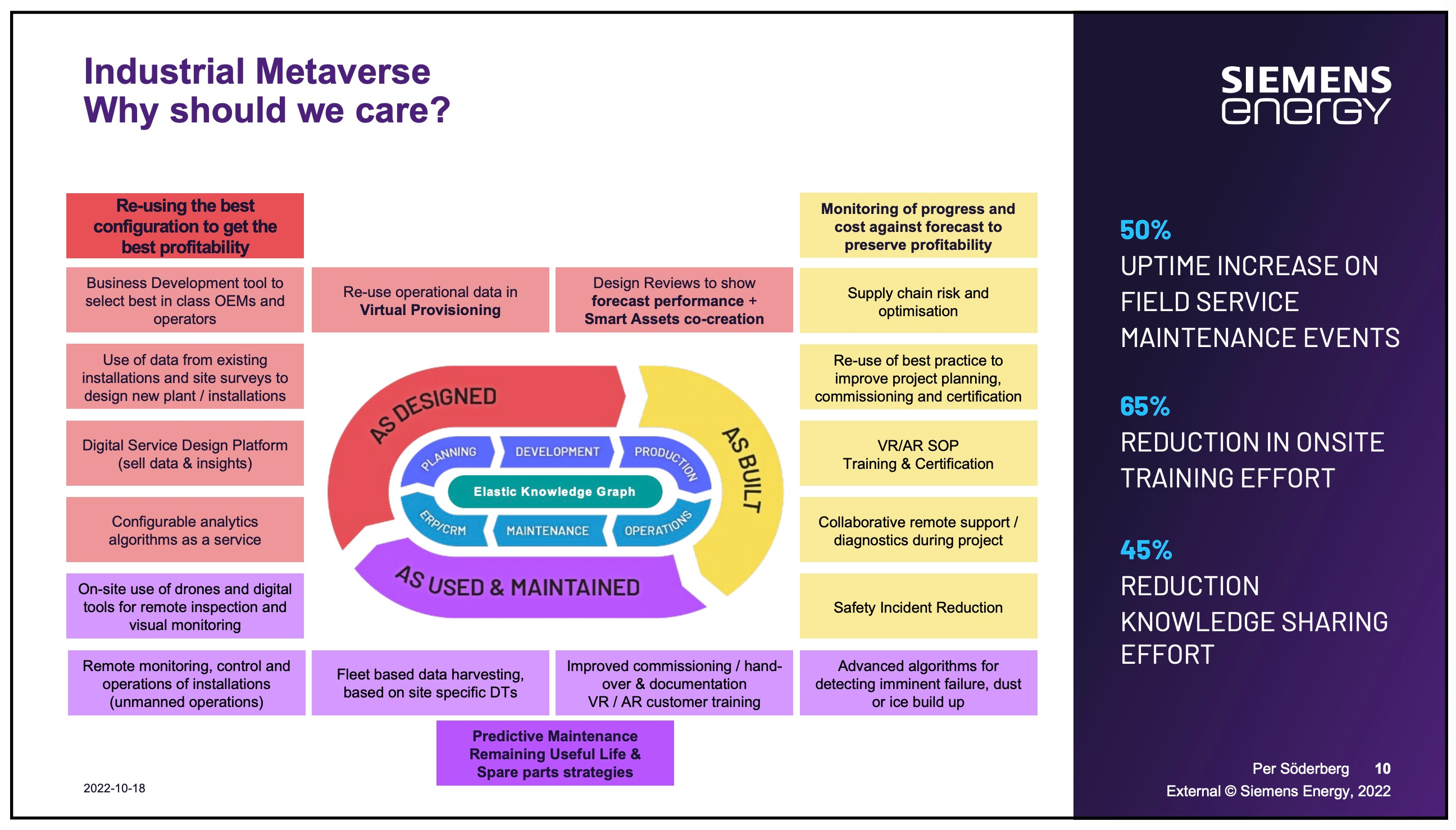

Another presentation about digital transformation mentioned by Jos during Day 2, was the Siemens Energy presentation. Per Soderberg, Head of Digital PLM at Siemens Energy, talked about their digital transformation project that started 6 – 7 years ago. Knowing the world of gas- and steam turbines, it is a domain where a lot of design and manufacturing information is managed in drawings. The ultimate vision from Siemens Energy is to create an Industrial Metaverse for its solutions as the benefits are significant.

The vision slide above is clearly my favorite. I found the idea of a knowledge graph super powerful. I was writing about Knowledge Graph and why should we care many times in my blog. Here are a few articles.

Why PLM needs to learn about Google Knowledge Graph?

Why Graph Knowledge Model is a Future of Manufacturing and Product Lifecycle?

From PLM data to manufacturing knowledge graph

I’ve been making multiple research work on how to use graph models in engineering and manufacturing applications for the last ten years. Some of my earlier work was in the development of applications using semantic models and RDF triple stores database. At OpenBOM (disclosure – I’m co-founder and CEO), we’ve been using graph databases to create a flexible data engine capable to capture and semantically organize information. Check some of the articles I published about Knowledge Graph on the OpenBOM blog. For example, check these two articles:

The foundation of product data-driven AI

OpenBOM Graph-Centered Applications

How To Share Data?

Jos’ articles from PDT Europe made me think about business processes, digital transformation, and how various engineering and manufacturing software such as product lifecycle management (PLM), product data management (PDM), and supply chain management will be transformed using digital technologies and turn all analog data into digital data. Companies are running multiple business systems, but managing data is becoming a tedious and complex process. While the business strategy of companies is discussing the business value of data and business leaders are talking about PLM systems that will help companies to bring business outcomes from digital transformation projects, the technology and customer experience are still lagging behind.

These are 5 things that I think should help manufacturing companies share data:

Maintain Reliable Data Sets

When it comes to the data, less is more. The biggest challenge is siloed data sets that for years were replicated without proper maintenance. Many organizations were focusing on “enterprise integrations”, but these programs were mostly focused on how to copy data between data silos instead of establishing meaningful information assets using modern digital technology with the future application of artificial intelligence and other analytics.

Another aspect of data management is related to very old PLM system architectures. Data sources in SQL databases with proprietary data schemas make it very hard to maintain up-to-date information sets and real-time data access combining engineering, customer, and partner information. All together represents a big challenge for new business models of global manufacturers focusing on how to organize efficient product value chains and maintain their goals related to cost, operation, sustainability, and many others.

Eliminate Data Storage in Documents

This one is killer. A huge amount of data is located in documents – CAD documents, Office documents, Excels, PDFs, and many others. The document paradigm is around for many years and it is the mainstream way for companies to manage data and data sharing. Extracting data from documents and turning it into granular shareable data sets – this is where the digital thread begins.

Align IT landscape using REST API and Web Services

A fragmented IT Landscape is another killer in existing data management systems. Large companies are operating redundant enterprise systems (eg. PLM, ERP) that must be consolidated. Many systems were connected with point-to-point integrations, extremely costly and inefficient. The systems are populating data siloes with limited capabilities to share data. Existing APIs are focusing on operation transactions and are not efficient for data sharing and contextual data visualization.

To build efficient methods of data organization all systems must be modernized and data must be available via REST API and web services. This is how data will become available to build decision-focused systems. This is also the next step for modern PLM system architecture. Data sharing and digital transformation require more data to be available in a contextual way.

Develop Flexible Adaptable Data Models

Many existing enterprise systems were developed without flexibility in mind. As a result data models of these systems are not adaptable and cannot be transformed to support new business processes and tasks. Modern PLM and other data management systems need to be focused on how to support flexibility in data modeling and data sharing. It includes modern data management architectures, including NoSQL and graph databases and related analytical capabilities.

Network of API to manage data handover and data sharing

The majority of old enterprise systems were built using single-tenant architecture. When these systems were designed, no one was thinking about companies using data management platforms capable to serve multiple companies. A network data management layer is a capability of the platform to connect multiple companies or business units of the same company operating independently, but collaboratively. These global platforms are very powerful when applied to independent OEMs, contract manufacturers, and supply chain partners. However, the same model can be used in an isolation by large enterprises limiting it to their own Tier1-n suppliers.

What is my conclusion?

Digital transformation of enterprise companies requires building an independent layer of data access and data sharing. The ideas of such a system have been around for a long time. The name of those systems. While Siemens Energy used the “Industrial Metaverse” name, many other names can come. The digital thread is a foundation of all these systems and requires building a scalable data management architecture that can represent the information in contextual shareable data assets connected with existing operational systems. The first step of such a system will not require changes to existing ERP, PLM, and other systems. The focus of data sharing will be to support decision-making. Such a layer can be built using multiple web services and combined together. Just my thoughts, for the moment. But it is a topic for my next blog. Stay tuned…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital cloud-native PDM & PLM platform that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.