The last two weeks were very busy for me and I’m still digesting what I learned last week at PTC LiveWorx 2023. It is great to see how physical events are coming back and LiveWorx 2023 was the first big event in Boston I attended after COVID-19 time. Check my previous article about LiveWorx 2023 experience.

Product lifecycle is getting very complex and manufacturing companies are continuously looking for a PLM technology that helps them to optimize an entire product lifecycle, to keep development costs low, organize efficient document management, and to invent a new communication system to help everyone to work faster in an entire lifecycle. It includes OEMs as well as extended enterprises these days including all contractors and suppliers.

PTC Roots are Faster, Better, and Cheaper

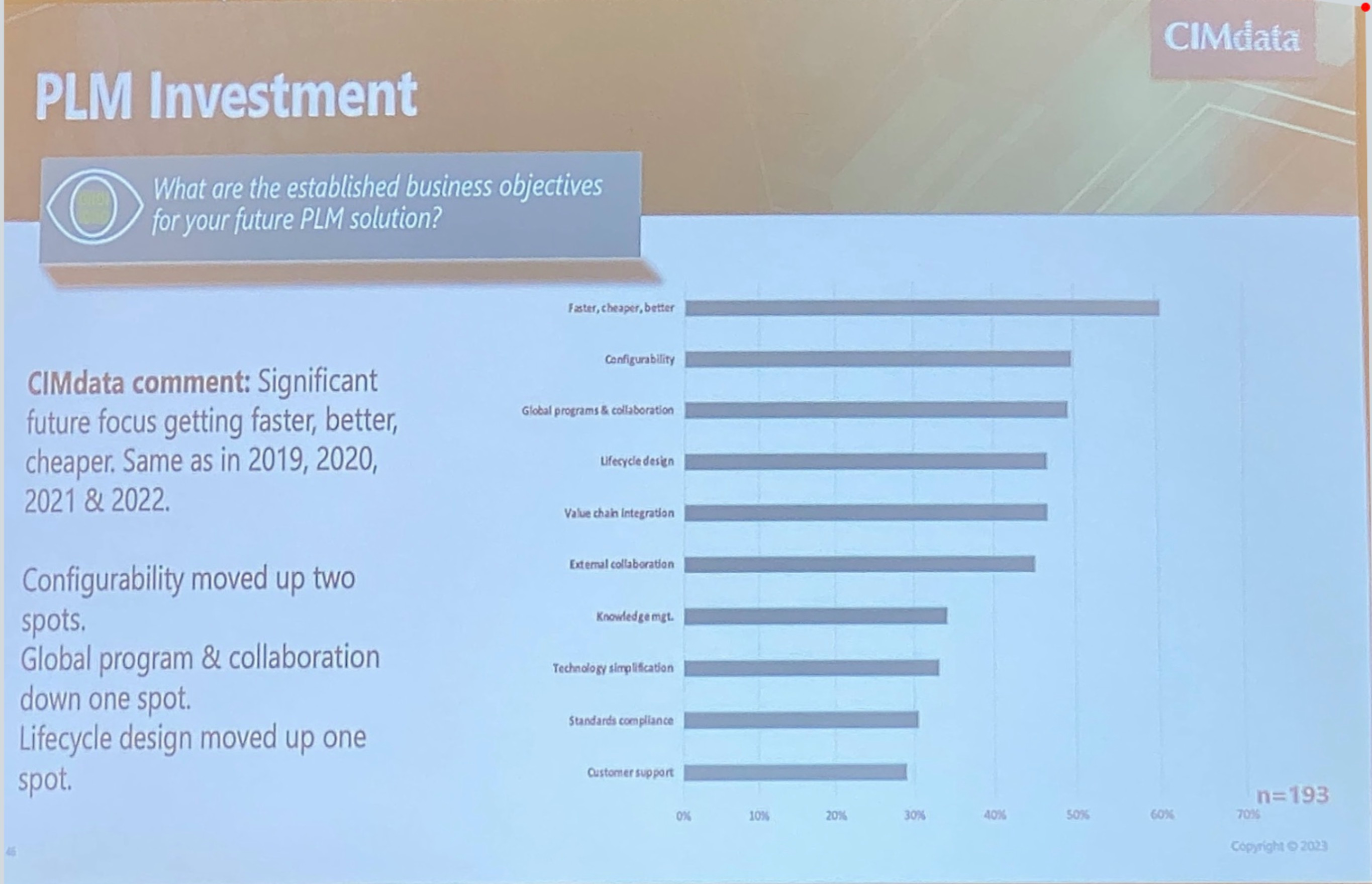

Manufacturing companies are continuously looking at how to develop better products faster at a lower cost. I guess you’re not surprised. We can see it confirmed as a top demand from manufacturing companies for the last four years (2019, 2020, 2021, 2022) CIMdata 2023 Market Forum. Check my writeup from the event – My top 5 important things about the state of PLM in 2023.

Speed was at the roots of PTC (Parametric Technology Corporation), which was founded by Sam Geisberg, a genius emigrant mathematician, who invented the mechanism, which became the foundational element of Pro/Engineer software and later was used by all MCAD software. It was much earlier before ideas of holistic product lifecycle management were introduced. Back in those days, it was about designing and building products and it was called CAD-CAM. One of the main engineering challenges CAD companies were focused on back in those days was how to document mechanical components, making design faster. PTC’s focus was on how to speed up the design process and make changes faster. Here is my favorite passage from Funding Universe written about Parametric Technology Corp history:

Geisberg’s software brought an important innovation to the CAD-CAM world that even his competitors conceded was revolutionary. His software could recognize a change in a single variable of a design and adjust the rest of the model accordingly. For example, a person designing a plane could change the length of the wings, and Geisberg’s CAD-CAM software would indicate what implications that change would have on the rest of the plane. The innovation sped up the design process and made it much easier for engineers to experiment with new ideas.

It was confirmed by many PTC customers back in the 1990s. Here is the passage from the NYT article which brings an interesting data point about the usage of Pro/Engineer by Motrolla to cut their design time more than in half.

Parametric’s software, conceived in 1985 by an emigre Russian mathematician named Samuel P. Geisberg, the company’s chairman, was designed to accommodate changes and give engineers the flexibility to do “what if” overhauls of designs, much as users of an electronic spreadsheet can easily revise financial data. Parametric customers are frequently able to halve their mechanical design time, analysts say. Motorola Inc., for example, recently used Parametric software to design its Micro Tac personal cellular telephone in 9 months instead of the usual 18, creating a phone half the size of Motorola’s previous models.

Digital Transformation Journey and Need for Speed

Time-consuming processes are a big deal in product development and manufacturing. Product lifecycle management often recognizes it as the hardest part. How to make it more efficient and faster?

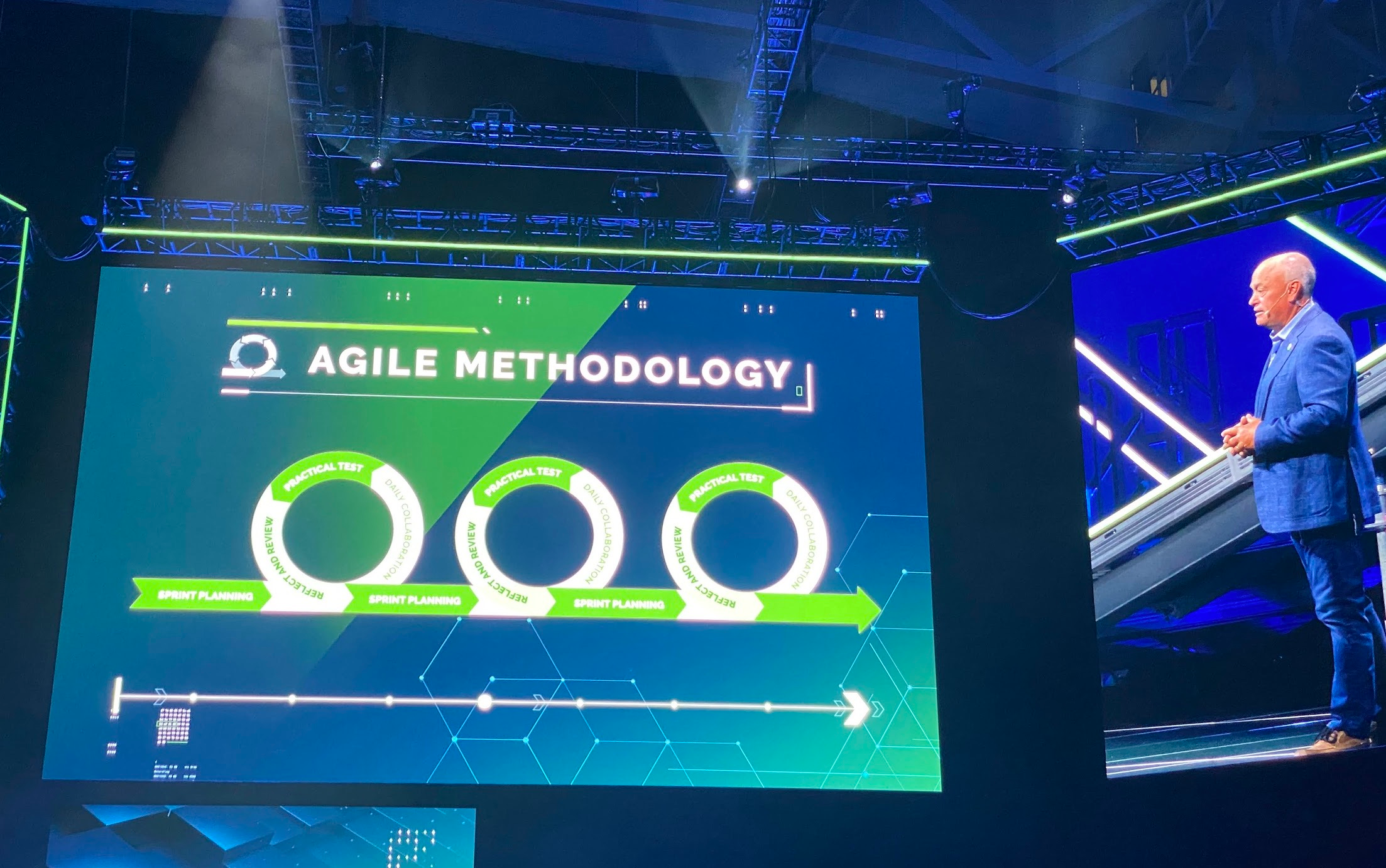

In the opening keynote by PTC CEO Jim Heppelmann, the message of “faster” played one of the key roles. Speaking about Digital Transformation, Digital Tread, and the Need for Speed, Heppelmann brings up an important change in the manufacturing – agile product development process.

The complexity of modern product development is unprecedented, but still, 80% of the cost is defined very early at the design change.

It was easier 40 years ago to design products faster. These days product development and manufacturing process is much more complex, which brings up It brings up the question of how the entire information lifecycle management in product development can be organized. In my view, it was always the hardest product lifecycle management holy grail.

Digital Thread – A Central Element of Product Development

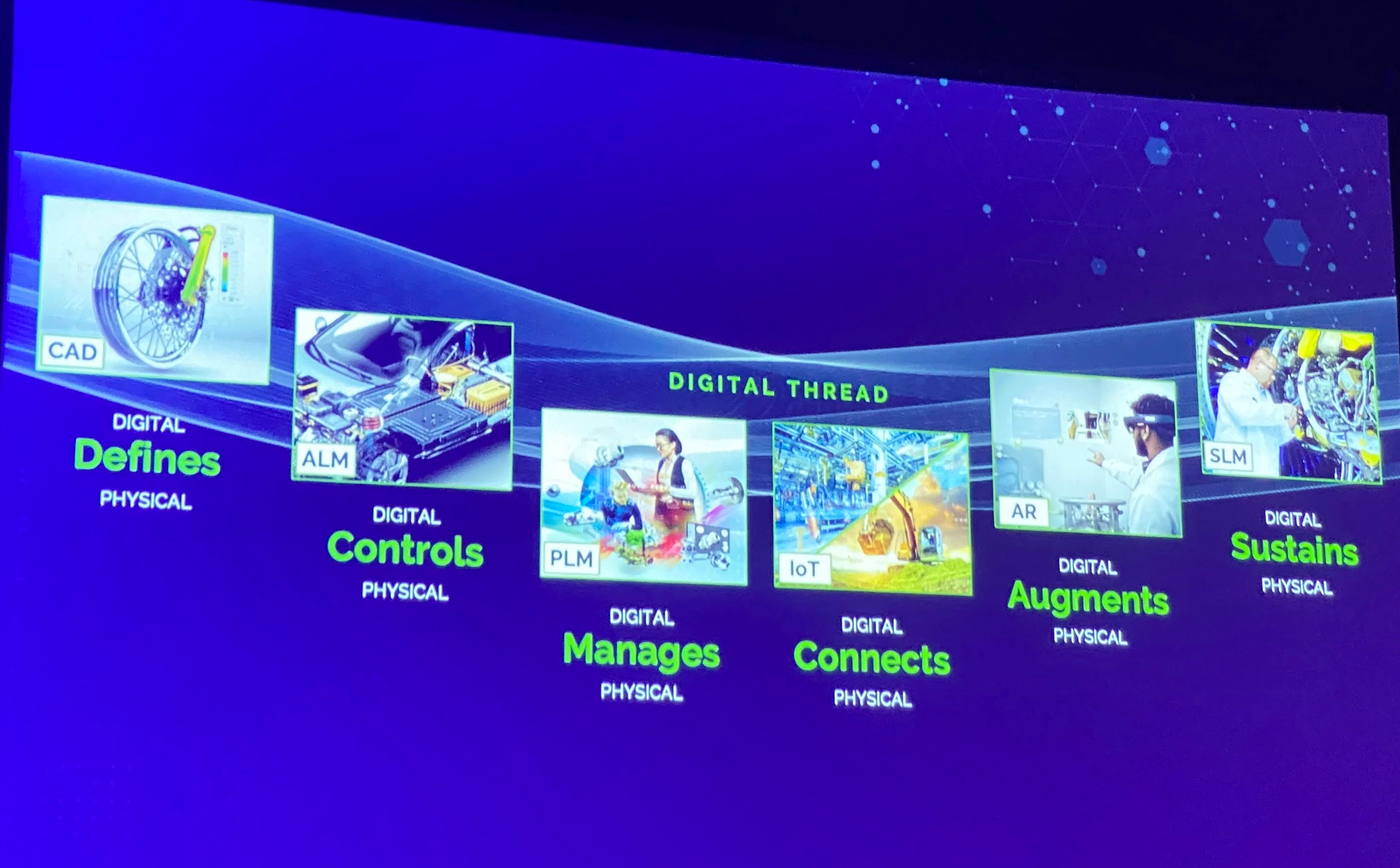

I think the digital thread was one of the most used combinations of words at LiveWorx 2023, bringing awareness of how important the connectivity of data, data sharing, and efficiency in modern product development.

Connecting different phases of product lifecycle management is a big deal and digital thread plays a key role in the process.

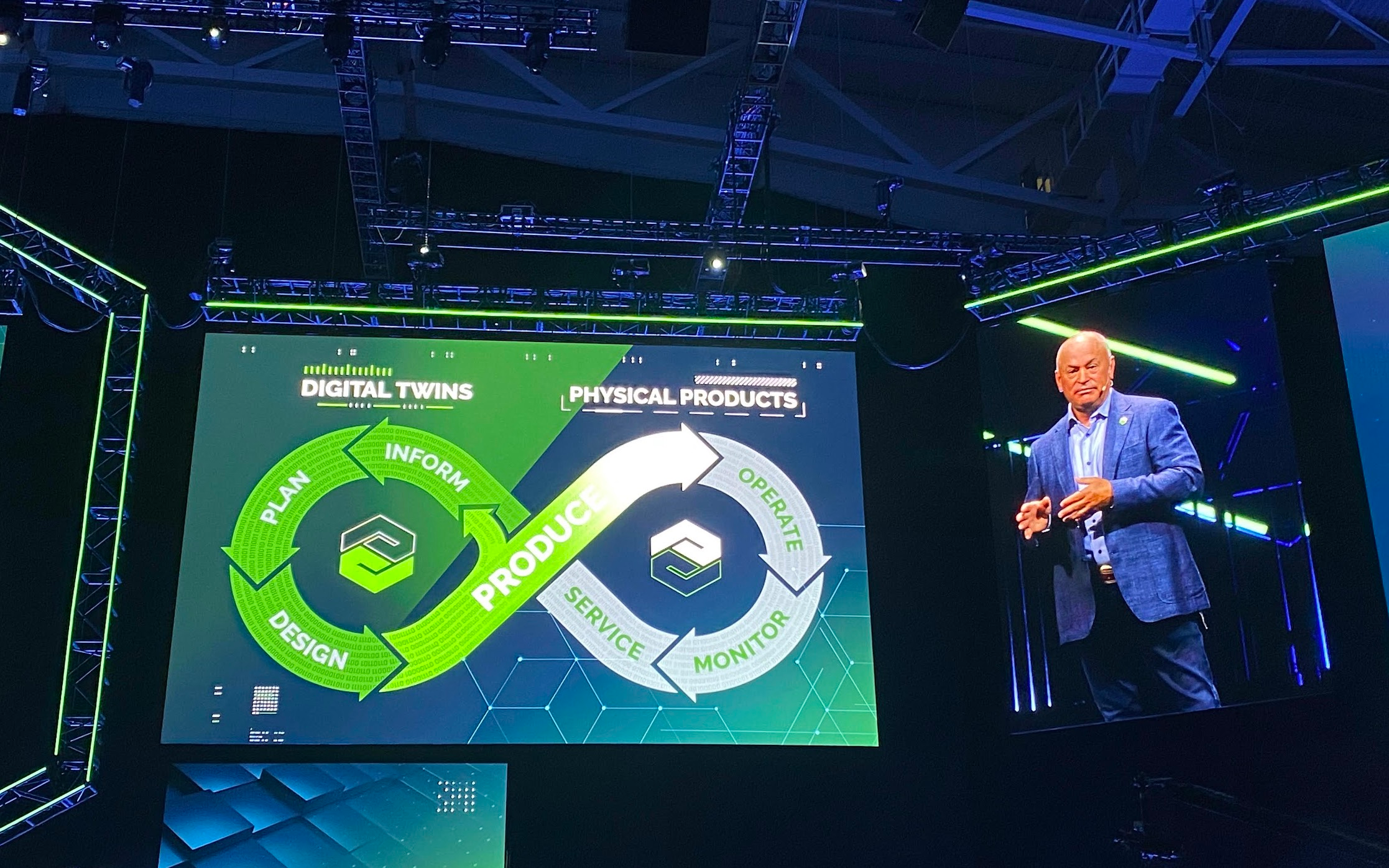

PTC’s vision was presented in the infinite loop of agile product lifecycle management connecting Yin and Yang – digital and physical products in a single operating system.

PTC spent $3B on development and acquisitions

For the last few years, PTC was spending heavily to support its vision of power to create, agile product development and holistic lifecycle in product lifecycle management. It included investment in SaaS CAD and PLM products, ALM, and service maintenance software.

You can see a broad portfolio of PTC now covering an entire product lifecycle management from the initial design where their core product (Creo) is the foundation of the efficient design process, expands in the modern agile cloud-based Onshape, expand software and ALM by Code Beamer and put a ground stake into service and assets for physical products connecting to ‘as-maintain’ and customer systems of records (CRM) with ServiceMax product.

What is my conclusion?

PTC demonstrated impressive growth and expansion of their vision of holistic product lifecycle management connecting existing product portfolio, recent development, and acquisitions into a network of products that can operate together to support modern product development and manufacturing processes. You can see all pieces of software and technologies covering different stages of multi-disciplinary design, production planning, SaaS foundation, and connecting both virtual and physical products together. The achievements are very impressive. I liked how Jim Heppelmann put all nuts and bolts of his vision together. The next PTC challenge in this journey will be to create a continuous information model of the digital thread. In the history of PLM, integration and building an informational continuum was one of the hardest parts of product lifecycle management. Connecting technologies, not losing flexibility, and supporting multiple industries would be the next thing I like to watch in PTC’s journey. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital thread platform including PDM/PLM and ERP capabilities that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.